Image sensor and forming method thereof

An image sensor and graphics technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problem of low sensitivity of photodiodes, and achieve the effect of good image and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] At present, when the image sensor is working, the incident light is first filtered into three monochromatic lights of red, blue and green through a filter, and then the corresponding photodiodes collect the corresponding optical signals, output electrical signals, and restore the image through difference calculation. . Since the photodiode only has the function of photoelectric conversion, in the case of weak light, the light sensitivity is not enough, which affects the imaging effect of the image sensor.

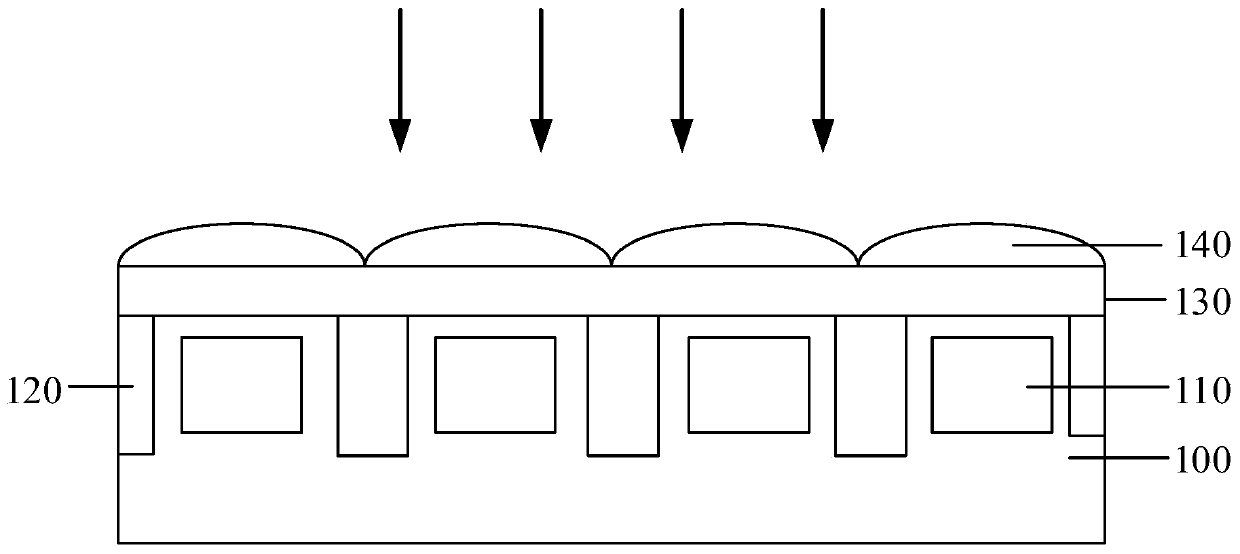

[0024] figure 1 is a structural schematic diagram corresponding to the formation process of the image sensor. refer to figure 1 , providing a semiconductor substrate 100, in which discrete photodiodes 110 are formed, and the discrete photodiodes 110 are isolated by deep trench isolation structures 120, and the depth of the deep trench isolation structures 120 is Deeper than the photodiode 110, so as to obtain a better isolation effect and avoid the problem of phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com