Piezoelectric element lead bonding method and piezoelectric element having pins

A piezoelectric element, lead welding technology, applied in the manufacture/assembly of electrical components, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of positive and negative electrodes of piezoelectric components Coating peeling off, welding process is difficult to strictly control, increase repair rate and other problems, to improve yield rate, improve heat dissipation effect, improve heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

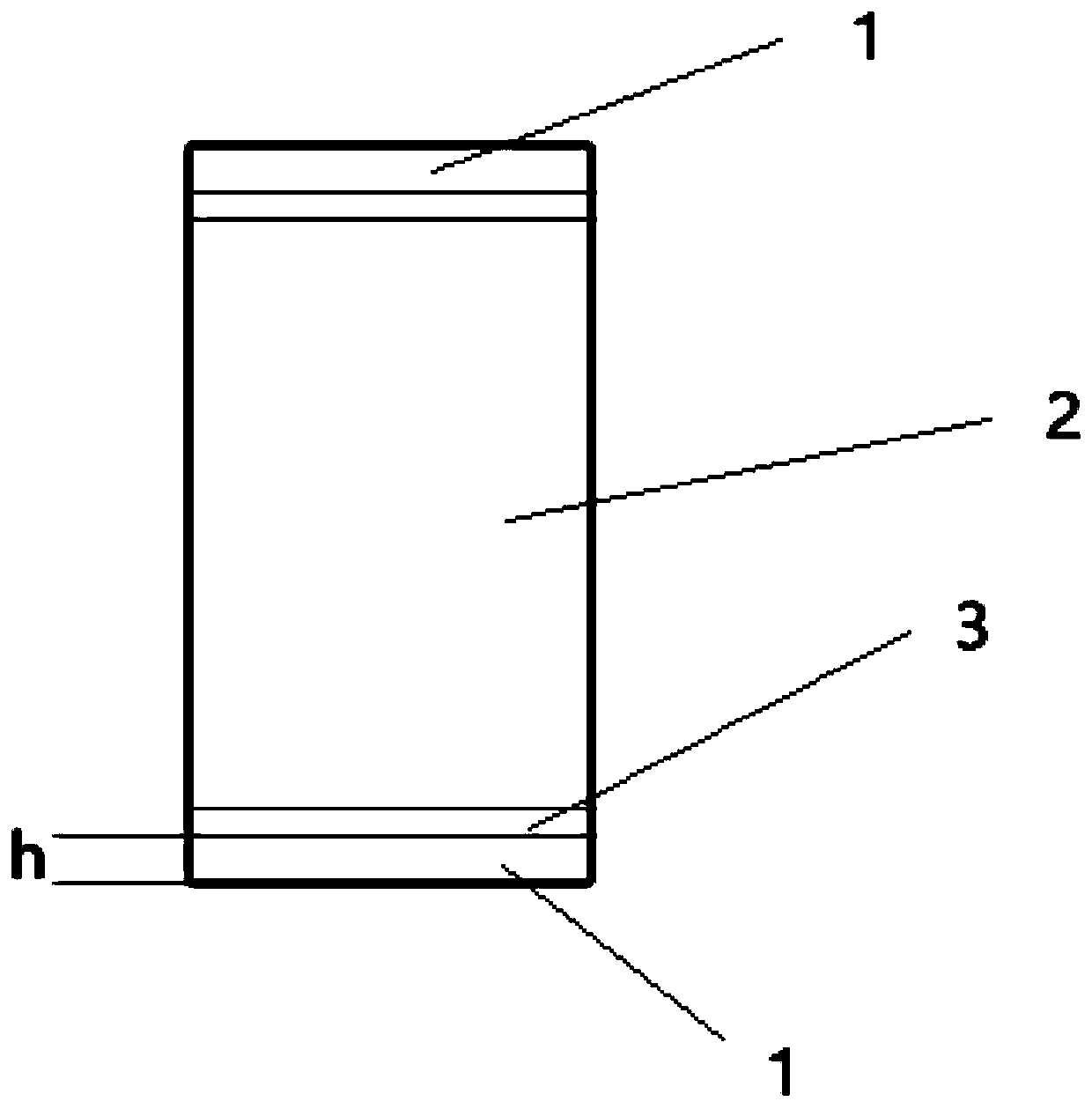

[0048] This embodiment provides a piezoelectric element lead welding method, including the following steps:

[0049] S1: bonding a layer of conductive metal layer 9 to the surface of the positive and negative electrodes of the piezoelectric element through glue;

[0050] S2: welding pins on the conductive metal layer 9 corresponding to the positive and negative poles of the piezoelectric element;

[0051] S3: Form a slit 6 along the isolation groove 3 of the piezoelectric element to cut the conductive metal layer 9 .

[0052] In the piezoelectric element lead welding method of the above-mentioned embodiments, the conductive metal layer 9 is bonded to the positive and negative surfaces of the piezoelectric element through conductive glue, and the pins are welded to the conductive metal layer 9. Since the pins are welded to the additional conductive On the metal layer 9, it is not directly welded with the coating of the piezoelectric element, which can prevent the coating from ...

Embodiment 2

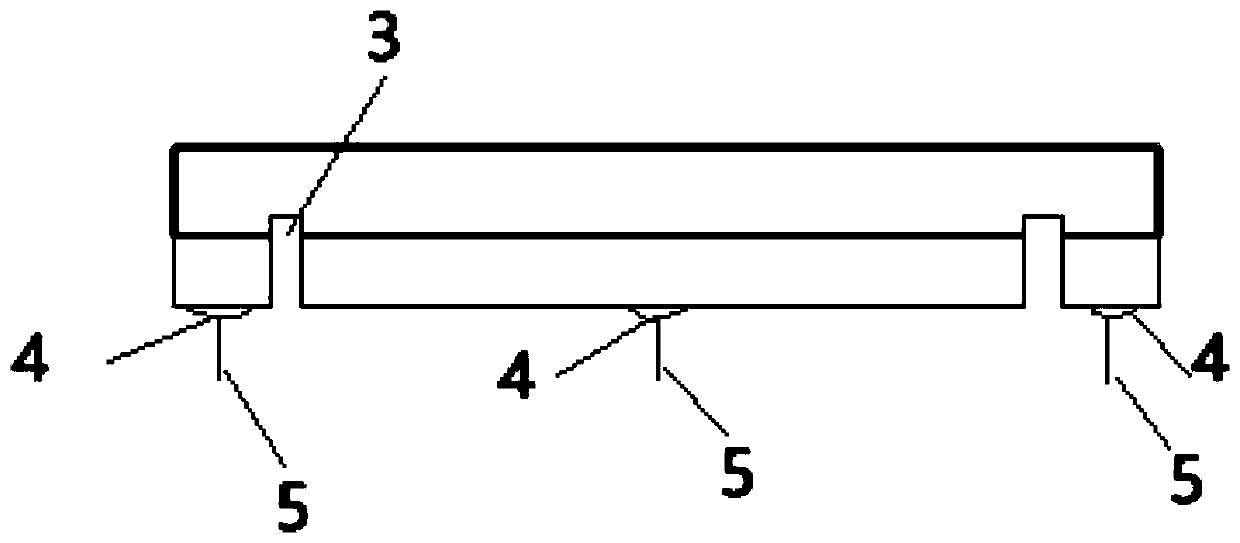

[0057] This embodiment provides a piezoelectric element lead welding method, including the following steps:

[0058]S1: Bond a layer of conductive metal layer 9 on the surface of the positive and negative electrodes of the piezoelectric element through conductive glue. The conductive metal layer 9 has extensions beyond the piezoelectric element on both sides of the piezoelectric element, and on the extension Forming several folding lines 7 along the direction parallel to the two sides of the piezoelectric element, and folding the conductive metal layer 9 along the folding lines 7 to form a bending portion 8;

[0059] S2: welding pins on the conductive metal layer 9 corresponding to the positive and negative poles of the piezoelectric element;

[0060] S3: Form a slit 6 along the isolation groove 3 of the piezoelectric element to cut the conductive metal layer 9, and cut off the excess conductive metal layer 9 along both sides of the piezoelectric element.

[0061] In the meth...

Embodiment 3

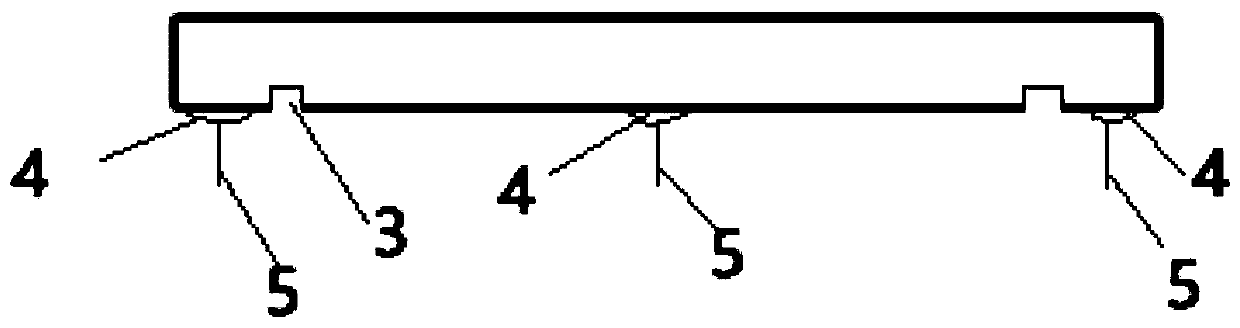

[0066] This embodiment provides a piezoelectric element with leads, which is obtained by welding the lead of the piezoelectric element in Embodiment 1 or 2. The structure of the piezoelectric element with pins such as image 3 As shown in or 4, the pin 5 is first connected to the conductive metal layer 9 through the solder joint 4, and the conductive metal layer 9 and the piezoelectric element are bonded into one body through conductive adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com