Myriawatt-level ultra-high-power all-fiber continuous fiber laser system

An all-fiber and laser technology, applied in the laser field, can solve the problems of dependence on imports, achieve the effect of simple structure and function design, easy commercial mass production, and realize commercial mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

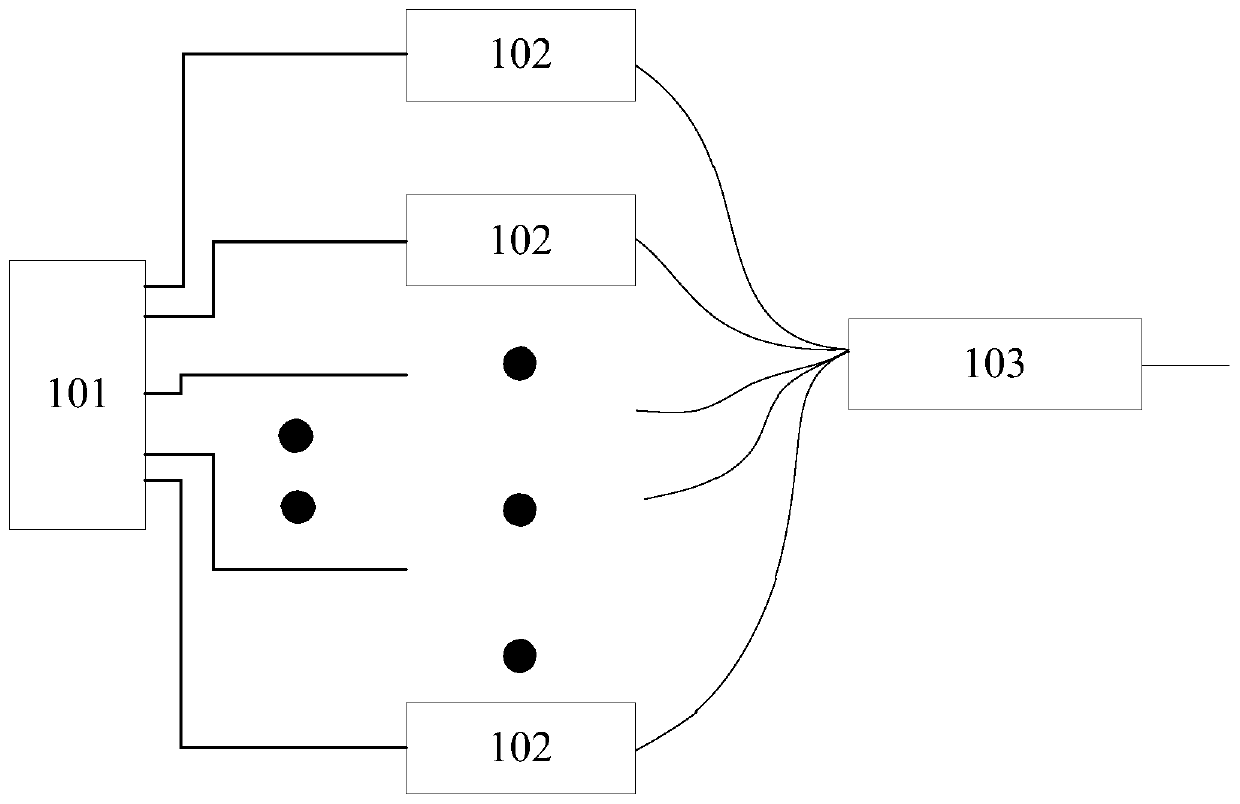

[0077] refer to figure 1 , shows a structural block diagram of a 10,000-watt-level ultra-high-power all-fiber continuous fiber laser system of the present invention, which may specifically include the following modules:

[0078] The total electronic control module 101, at least one laser module 102 respectively connected to the total electronic control module, and the laser synthesis module 103 connected to the output end of the at least one laser module;

[0079] The total electronic control module 101 is used to respectively control the opening or closing of each of the laser modules 102, and monitor the operating status of each of the laser modules 102 and the laser synthesis module 103;

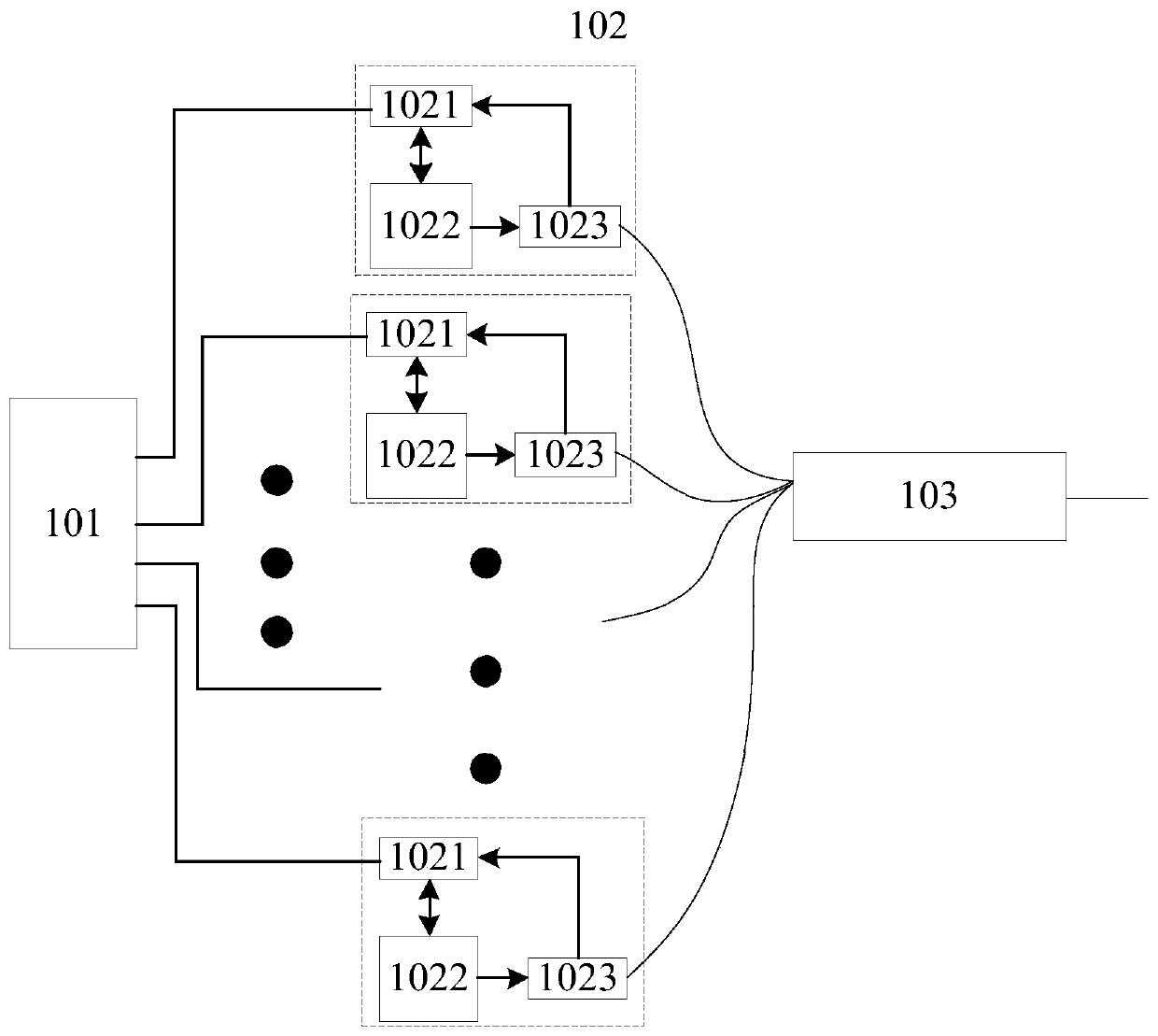

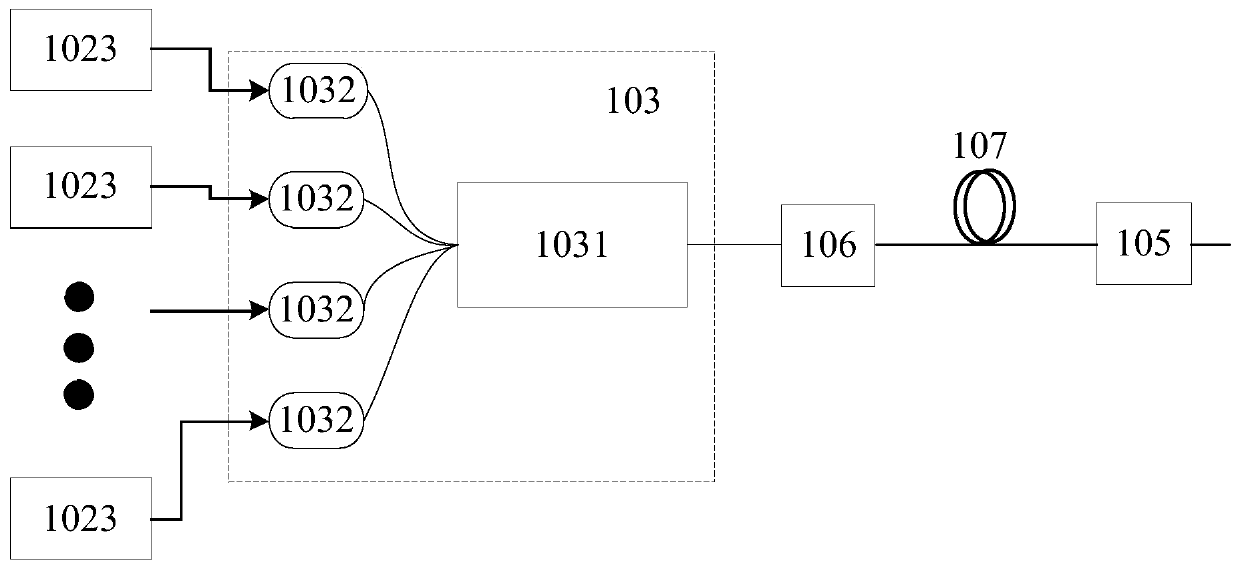

[0080] The laser module 102 is config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com