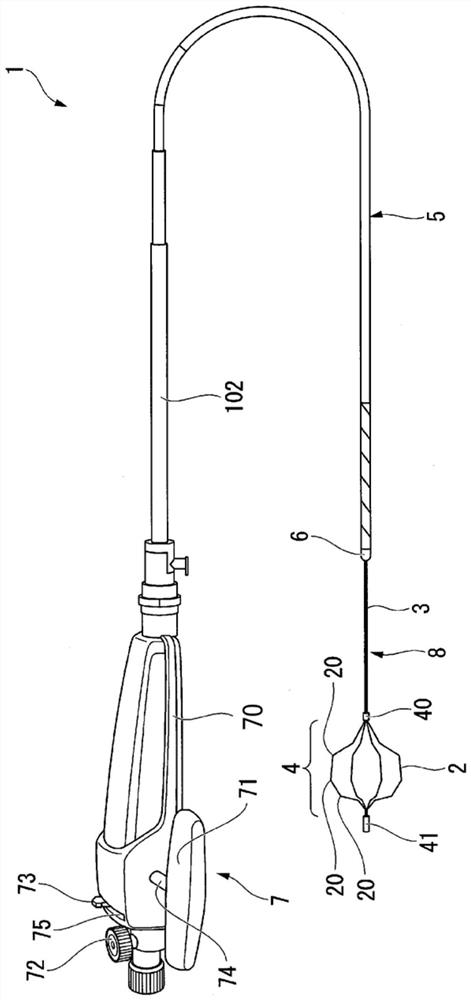

Stone Basket Disposal Appliance

A technology for disposing of instruments and basket lines, which is applied in the fields of medical science, surgery, diagnosis, etc., can solve the problems of inability to maintain and pull out the stone extraction basket from the pipeline, etc., and achieve the effect of easy removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

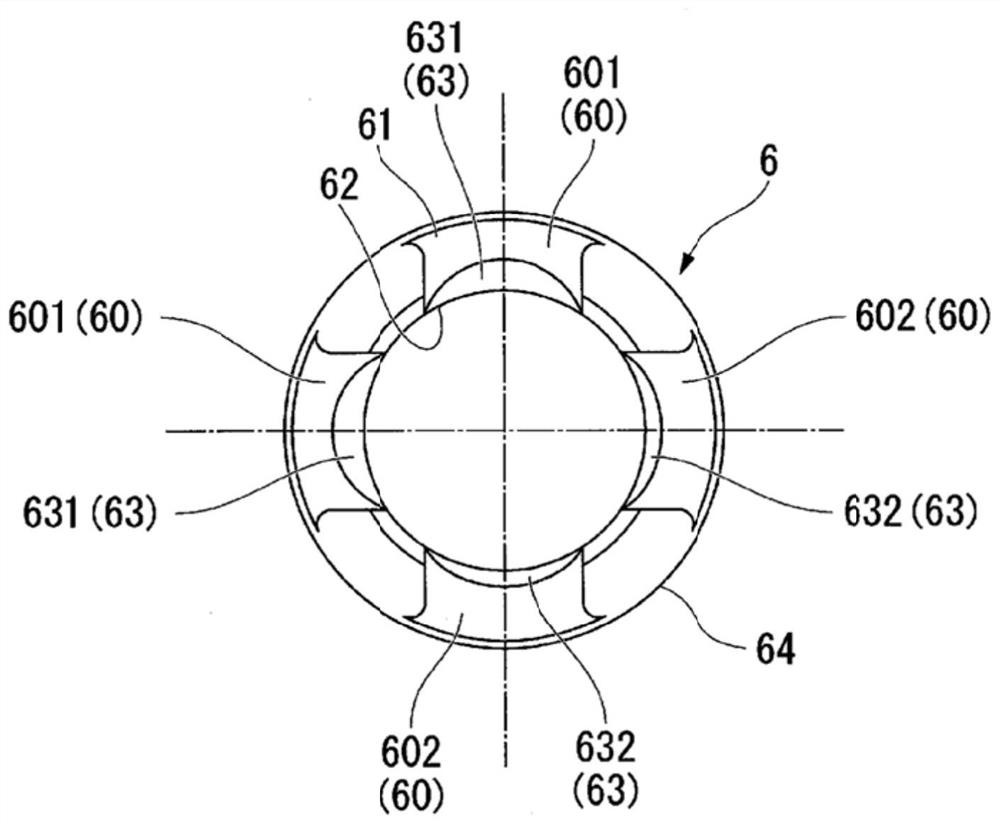

[0067] Modifications of the tip cover of the above-described embodiment will be described. Figure 9 It is a schematic diagram which shows the structure of the modification 1 of the said embodiment. In this variant, as Figure 9 As shown, the first surface 631A of the tip cover 6A is an R-angled surface, the second surface 632A is a C-angled surface, and the inclination angle and the amount of chamfering are the same. In this modification, when the stone basket wire 2 contacts the corner formed at the boundary between the second surface 632A and the bottom 61 or the corner formed at the boundary between the second surface 632A and the inner peripheral surface 62, the Stress tends to concentrate at this contact location. On the other hand, since the first surface 631A is an R-angled surface and no corner such as the second surface 632A is formed, it is less likely to be broken than the basket wire 2 passing through the second groove 602 . In this way, even if the amount of c...

Deformed example 2

[0069] Figure 10 It is a schematic diagram which shows the structure of the modification 2 of the tip cover of the said embodiment. The inclined surface of the top end cover is not limited to the R angle surface and the C angle surface, but can also be as Figure 10 Shown is the inclined surface 63B in which the C-angle surfaces with slightly different inclination angles are continuously formed. exist Figure 10 In the shown modification, the length m2 of the 1st surface 631B and the 2nd surface 632B differs. In this modification, the length m22 of the second surface 632B is shorter than the length m21 of the first surface 631B. Therefore, when tension is applied to the stone extraction basket wire 2, the stone extraction basket wire 2 passing through the second groove 602 is acted with a larger breaking force than the stone extraction basket wire 2 passing through the first groove 601, which is different from that of the stone extraction basket wire 2 passing through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com