Frozen-dried yoghourt product, component and preparation method of frozen-dried yoghourt product

A technology for dairy products and freeze-drying, which is applied in milk preparations, dairy products, applications, etc., can solve the problems of broken freeze-dried yogurt products, poor taste, unfavorable transportation or storage, etc., and achieve the effect of preserving nutritional value and rich taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A freeze-dried yogurt product, weighed according to the following components:

[0077] Yogurt 60 parts by weight;

[0078] 20 parts by weight of banana pulp;

[0079] 5 parts by weight of candied pineapple pulp.

[0080] Washing, sterilizing and beating the fruits and vegetables to prepare fresh fruit and vegetable pulp for later use. Add spare banana pulp (fresh fruit and vegetable pulp) to yogurt to obtain the first mixed material, measure the sweetness value of the first mixed material, and then control the amount of candied pineapple pulp according to the sweetness value of the first mixed material, and control the second mixed material The sweetness value is between 20 and 30 degrees. After mixing, the homogeneous yoghurt mixture is injection-molded, and then the molded material is quick-frozen until the temperature at the central position is ≤-25° C. to obtain a shaped material. The shaped material is subjected to vacuum freeze-drying to obtain a freeze-dried ...

Embodiment 2

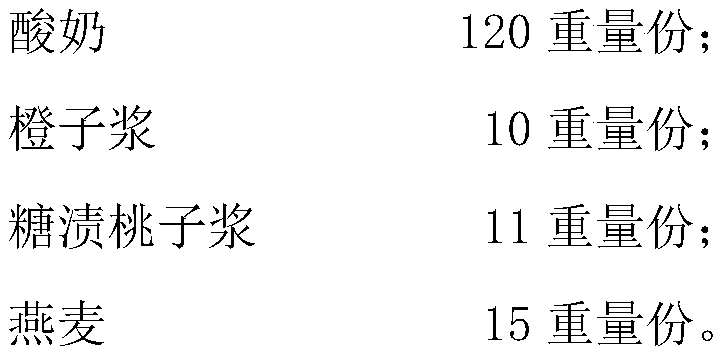

[0082] A freeze-dried yogurt product, weighed according to the following components:

[0083]

[0084] Washing, sterilizing and beating the fruits and vegetables to prepare fresh fruit and vegetable pulp for later use. Add spare orange pulp (fresh fruit and vegetable pulp) and oats to yogurt to obtain the first mixed material, measure the sweetness value of the first mixed material, and then control the amount of candied peach pulp according to the sweetness value of the first mixed material, and control the second The sweetness value of the mixed material is 20-30 degrees. After mixing, the homogeneous yoghurt mixture is injection-molded, and then the molded material is quick-frozen until the temperature at the central position is ≤-25° C. to obtain a shaped material. The shaped material is subjected to vacuum freeze-drying to obtain freeze-dried yogurt product 2.

Embodiment 3

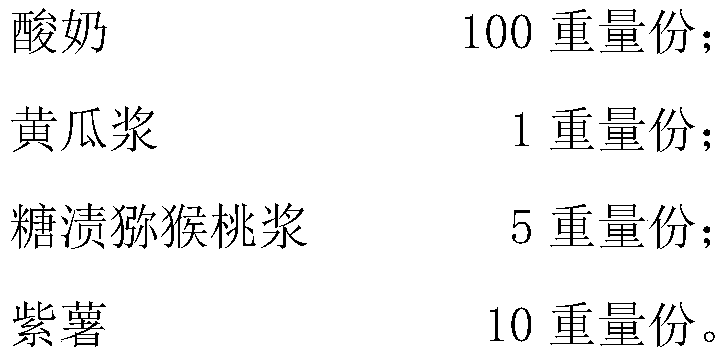

[0086] A freeze-dried yogurt product, weighed according to the following components:

[0087]

[0088] Washing, sterilizing and beating the fruits and vegetables to prepare fresh fruit and vegetable pulp for later use. Add spare cucumber pulp (fresh fruit and vegetable pulp) and purple sweet potato to yogurt to obtain the first mixed material, measure the sweetness value of the first mixed material, and then control the amount of candied kiwi fruit pulp according to the sweetness value of the first mixed material, and control the second The sweetness value of the secondary mixture is 20-30 degrees. After mixing, the homogeneous yoghurt mixture is injection-molded, and then the molded material is quick-frozen until the temperature at the central position is ≤-25° C. to obtain a shaped material. The shaped material is subjected to vacuum freeze-drying to obtain freeze-dried yogurt product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com