A cleaning mechanism for brickwork exterior walls based on the operating arm of a cleaning vehicle

A cleaning mechanism and exterior wall cleaning technology, applied in cleaning machinery, carpet cleaning, cleaning equipment, etc., can solve the problems of no wall cleaning mechanism, inappropriate cleaning of brick exterior walls, etc., and achieve stable expansion and rotation offset. Reliable, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

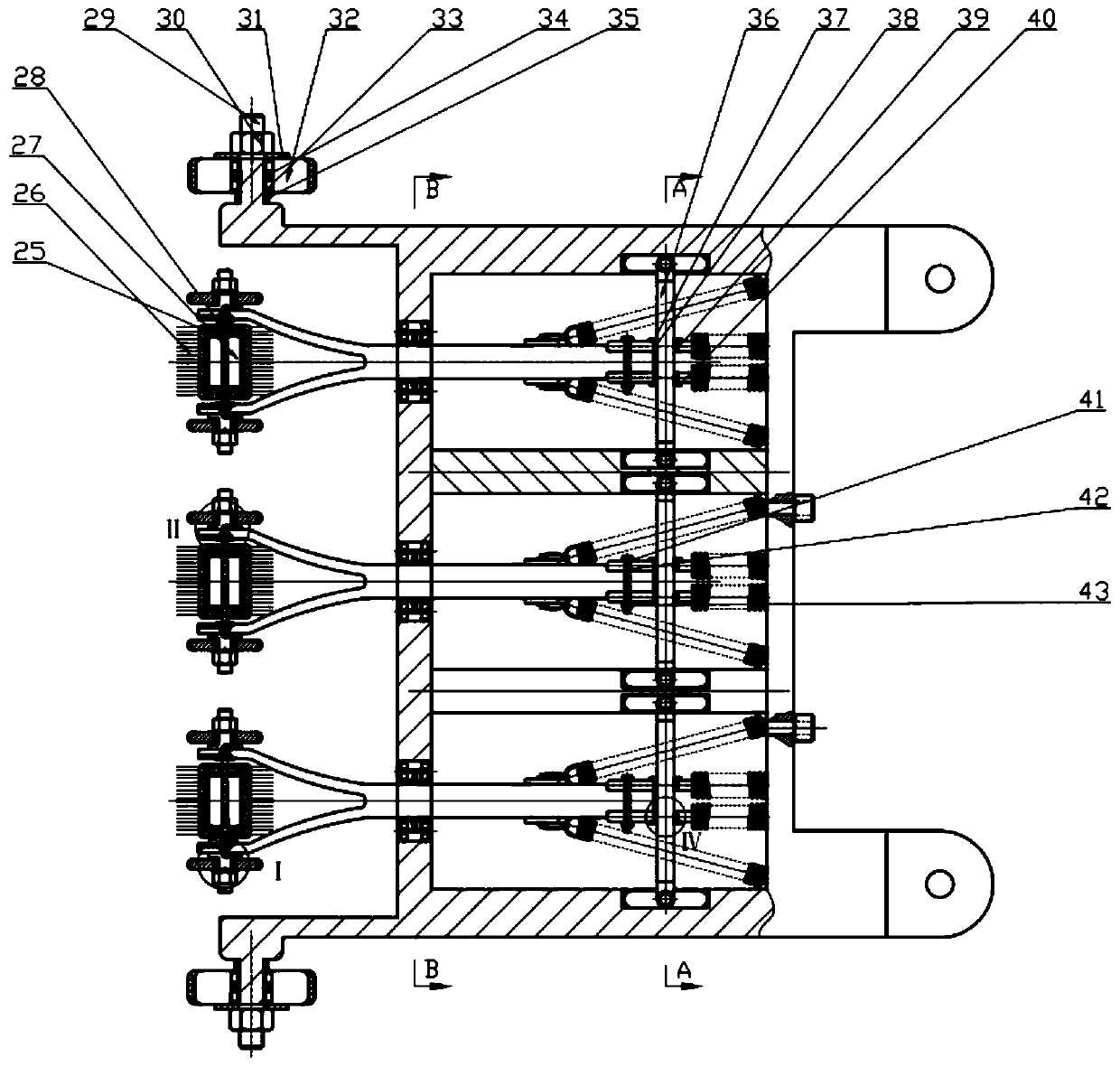

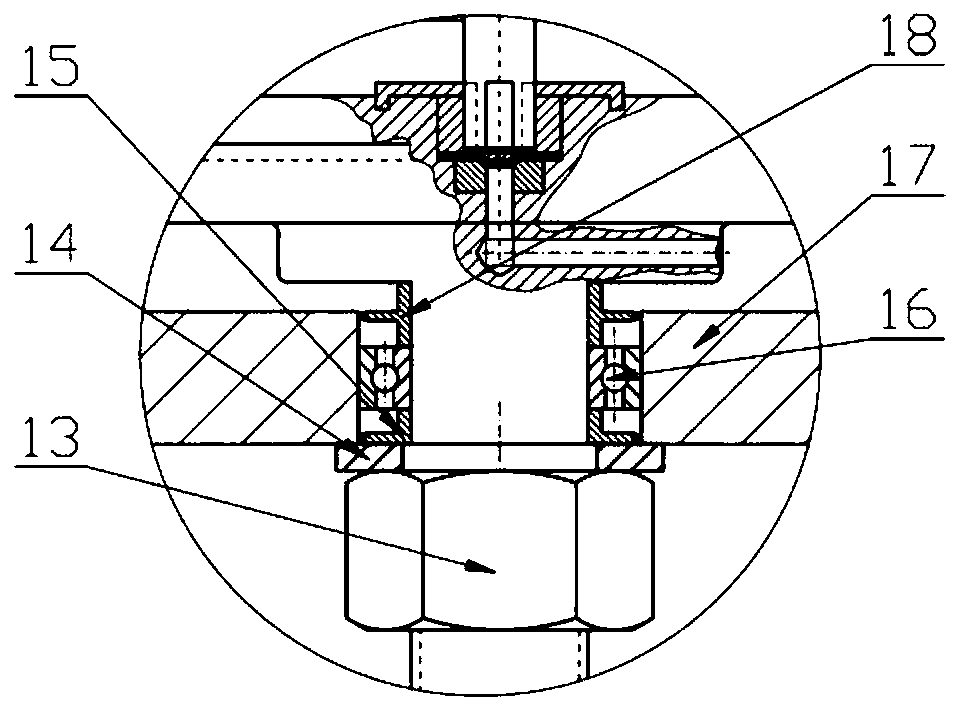

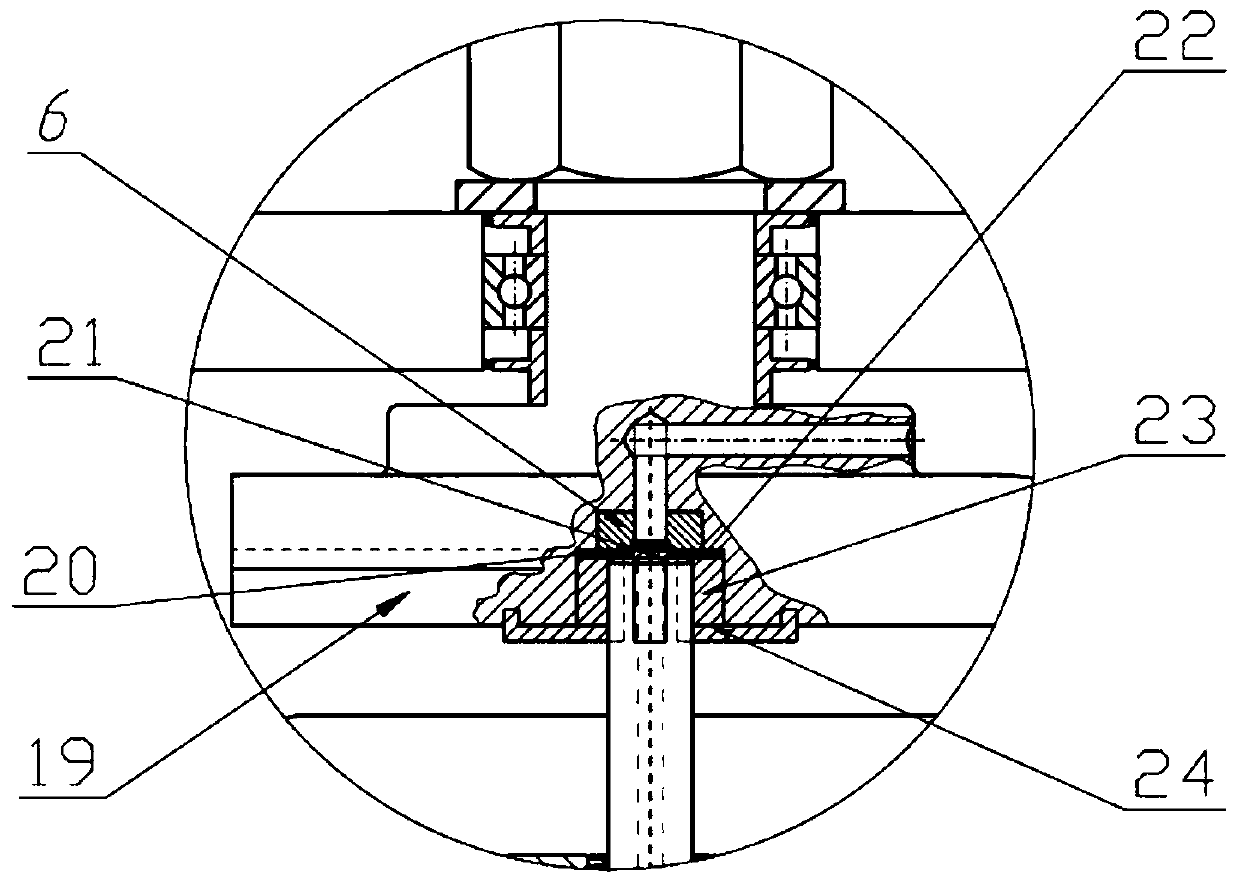

[0051] Such as figure 1 , Figure 5 , Figure 7 As shown in the three views, the present invention provides a brickwork exterior wall cleaning mechanism based on the operating arm of the cleaning vehicle, which includes an outer frame of the cleaning mechanism, an elastic tracking and rotation offset structure, a rolling brush cleaning structure and a cleaning liquid delivery device.

[0052] The outer frame of the cleaning mechanism is a cuboid frame structure, and the four corners of one side are processed with frame earrings 2, and the bolt holes 1 are processed on the earrings 2, and the cleaning mechanism is connected to the front end of the cleaning vehicle operating arm through bolts; the processing is organic The side of frame earring 2 is a fixed surface, and the side opposite to the fixed surface is a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com