Control device and system of laser cutting gas path

A gas circuit control and laser cutting technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor laser cutting process reliability, damage to the fiber of the laser generator, bursting of the gas pipeline, etc., to avoid problems such as The effect of pipeline bursting, improving the degree of purity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

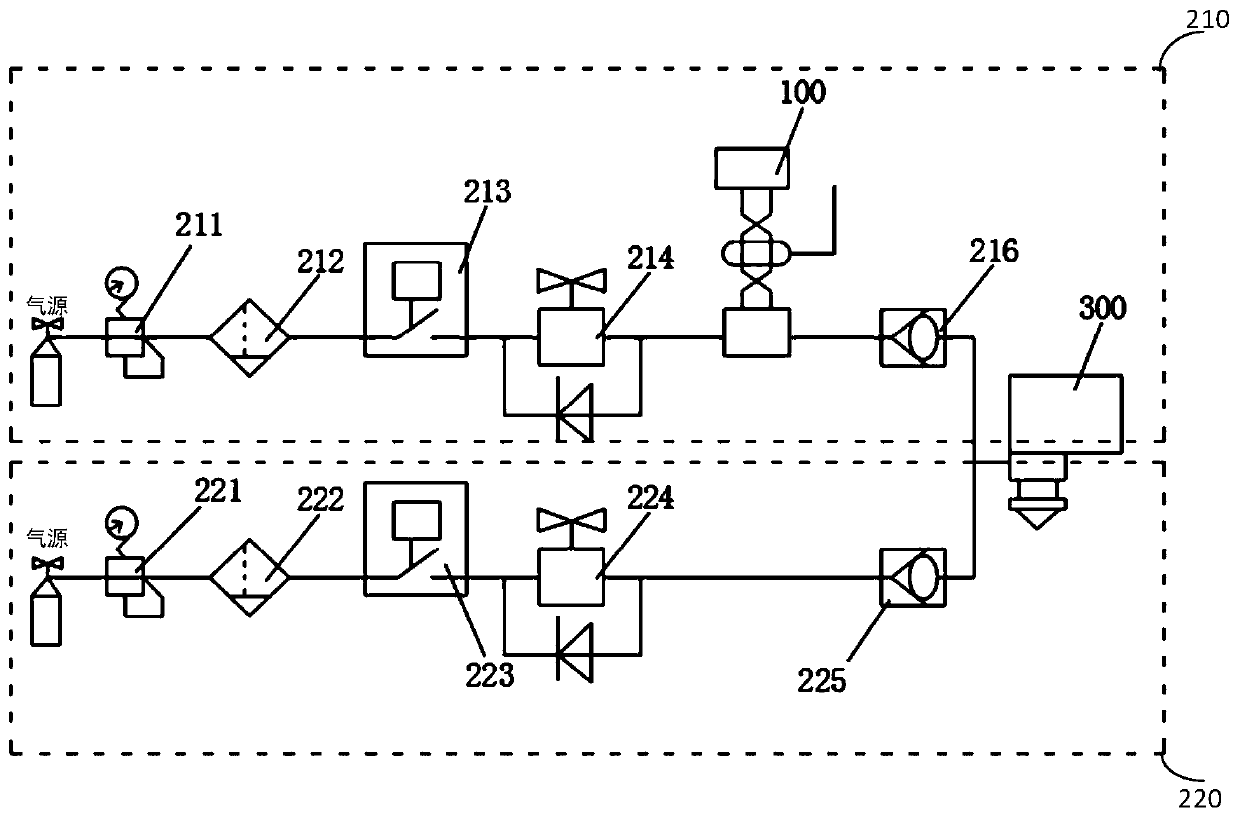

[0044] figure 1 It is a schematic diagram of a gas path control device for laser cutting provided by Embodiment 1 of the present invention.

[0045] refer to figure 1 , the laser cutting gas circuit control device mainly includes a control system 100 , at least one gas pipeline and a cutting head input port 300 . The control system can adopt CNC control system or board control system.

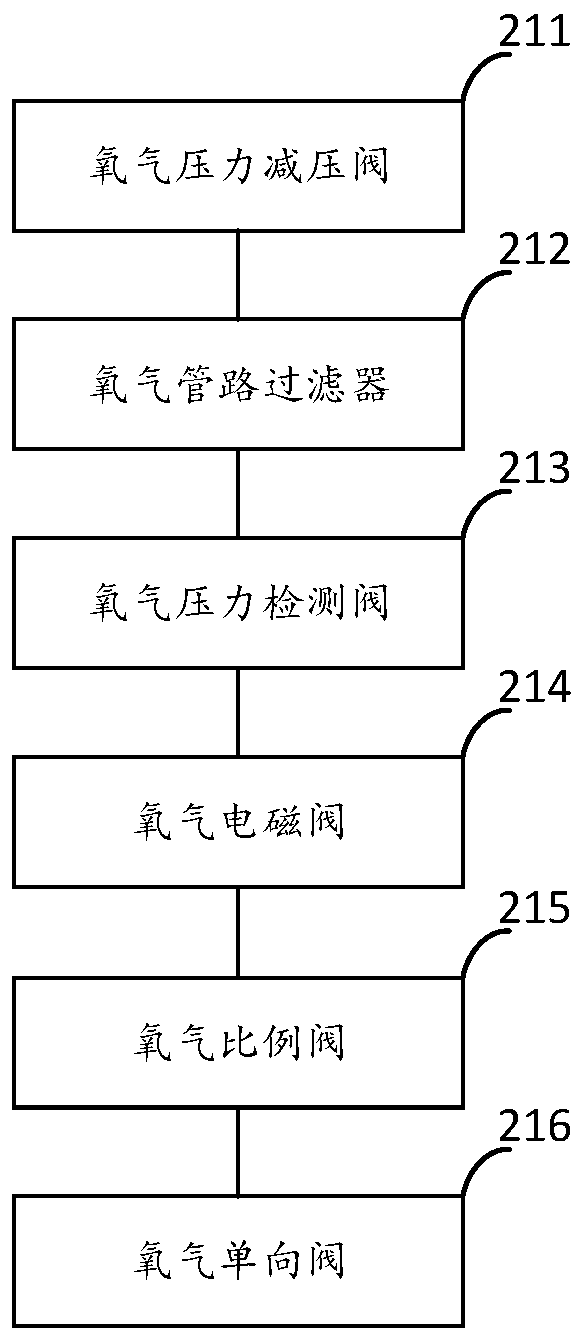

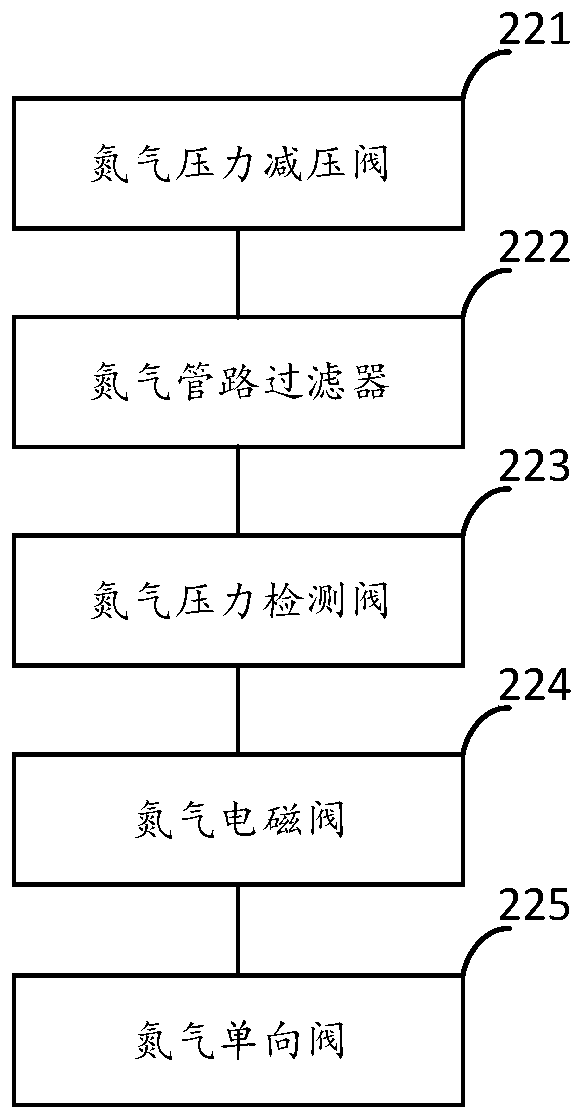

[0046] Further, each gas pipeline includes a gas pressure reducing valve, a pipeline filter, a pressure detection valve, a solenoid valve and a one-way valve connected in sequence; wherein, the pressure detection valve and the solenoid valve in each gas pipeline All are connected with the control system; the one-way valve of each gas pipeline is connected with the input port 300 of the cutting head.

[0047] In this embodiment, two gas pipelines will be taken as an example for illustrative description. Wherein, the first gas pipeline is an oxygen pipeline 210 , and the second gas pipeline i...

Embodiment 2

[0085] Figure 4 It is a schematic diagram of a gas path control system for laser cutting provided by Embodiment 2 of the present invention.

[0086] refer to Figure 4 , the gas path control system for laser cutting includes the gas path control device for laser cutting as in the first embodiment above, and also includes a plate 400 .

[0087] The plate 400 is arranged below the input port 300 of the cutting head in the gas circuit control device for laser cutting. During processing, the cutting head input port 300 and the plate 400 keep a certain distance between the cutting head input port 300 and the cutting plate 400 according to the processing technology requirements. The distance in this embodiment is within the range of 0.3mm-15mm. The required gas supply is provided directly to the processing of the plate 400 .

[0088] A gas circuit control system for laser cutting provided by the above-mentioned embodiments of the present invention includes a control system, at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com