Drum brake neglected assembling preventing semiautomatic assembling equipment

A technology for drum brakes and assembly equipment, which is applied to metal processing equipment, assembly machines, manufacturing tools, etc. It can solve the problems of unguaranteed product quality, low production efficiency of assembly process, and high labor intensity, so as to ensure the tightening quality and avoid The effect of not tightening in place and avoiding grease loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

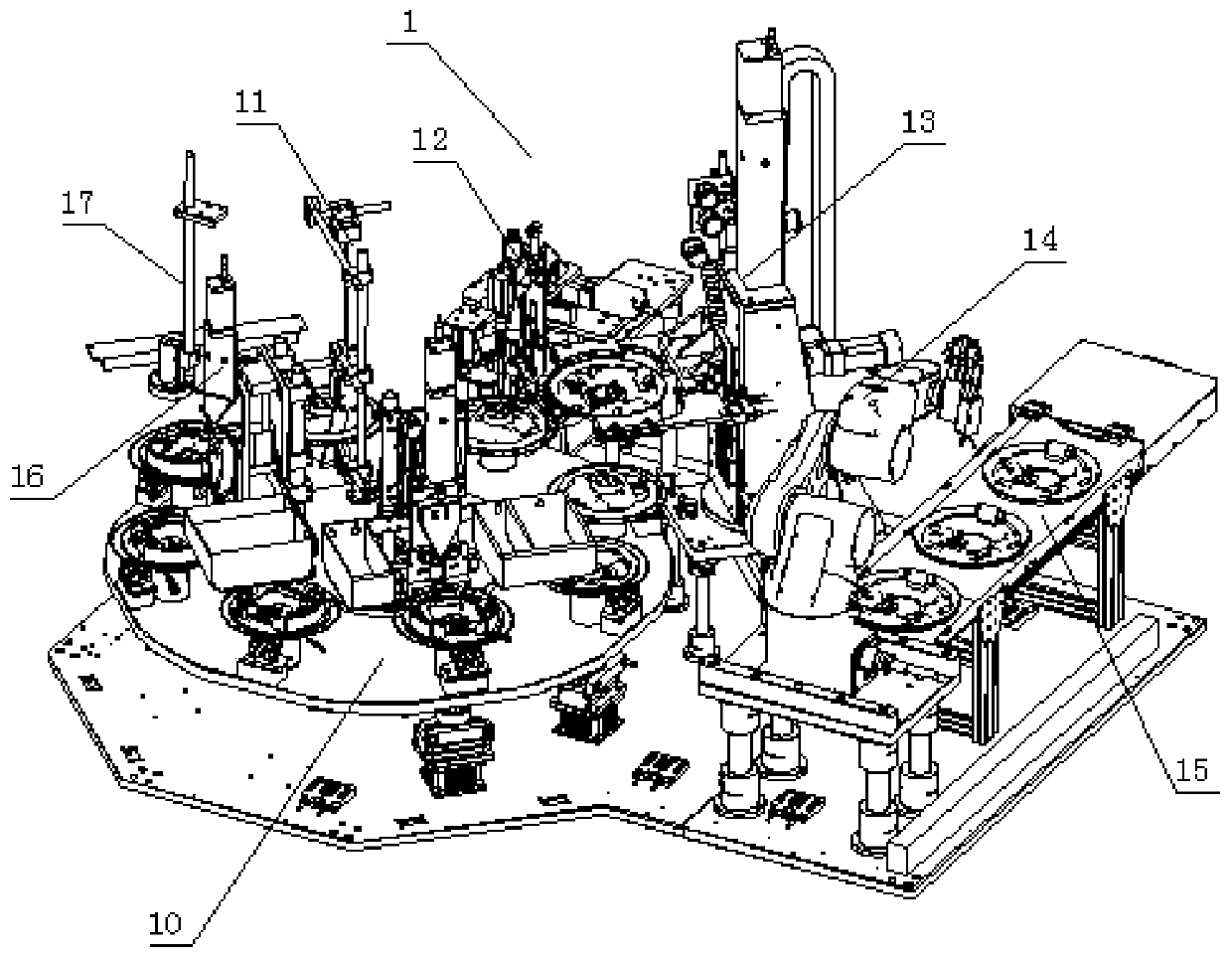

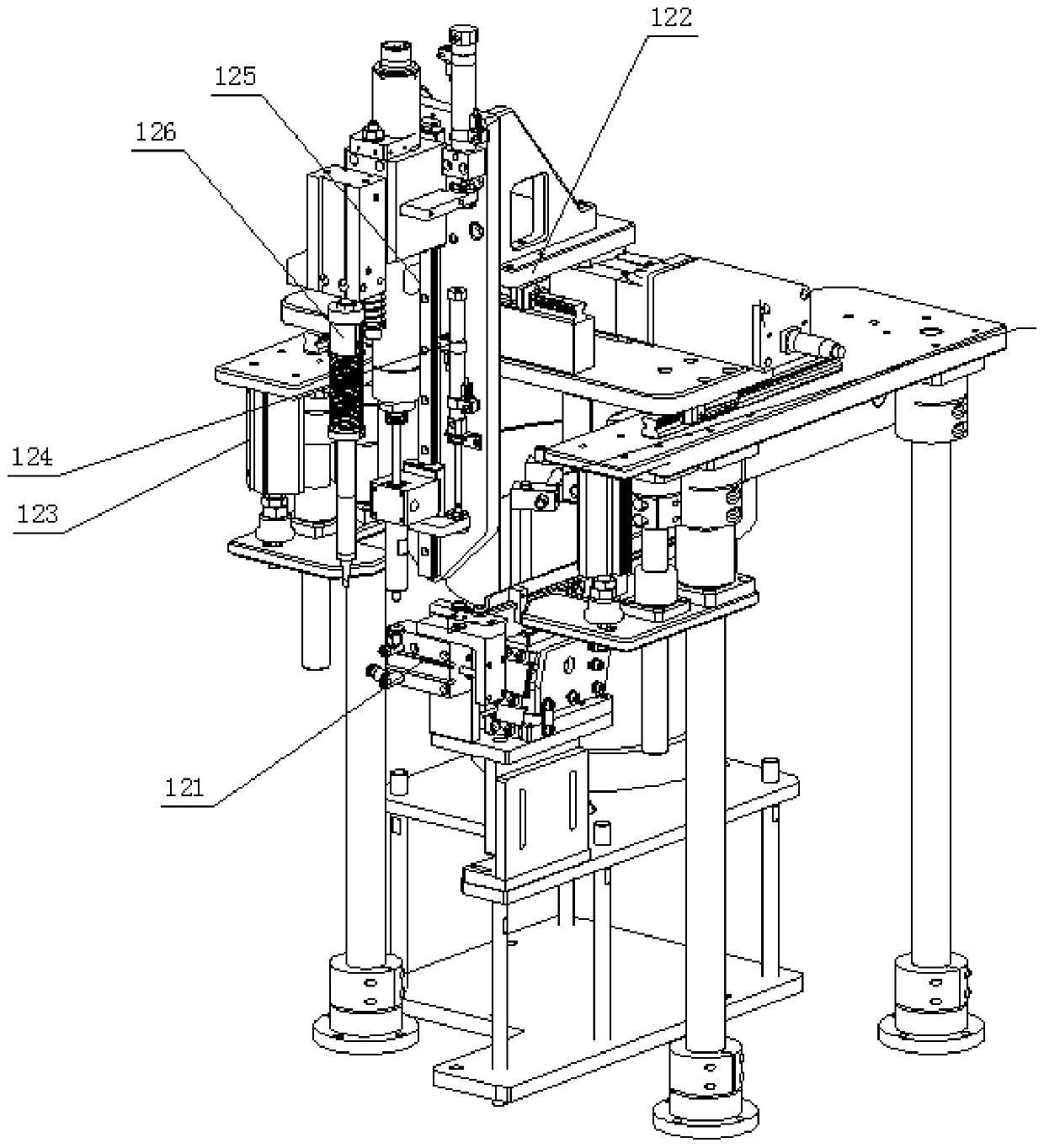

[0041] Such as Figure 1 to Figure 8 As shown, a leak-proof semi-automatic assembly equipment for drum brakes, including:

[0042] The eight-station rotating mechanism 10 includes an eight-station divider, a turntable driven by the eight-station divider, and workpiece positioning fixtures installed uniformly along the circumference of the turntable. Station conversion, eight stations include loading and inspection station, automatic bolt tightening station, lifting and turning station, automatic oiling station, manual assembly station, manual assembly and visual inspection station, and unloading station , there is also an empty station, which can be set between the manual assembly station, manual assembly and visual inspection station.

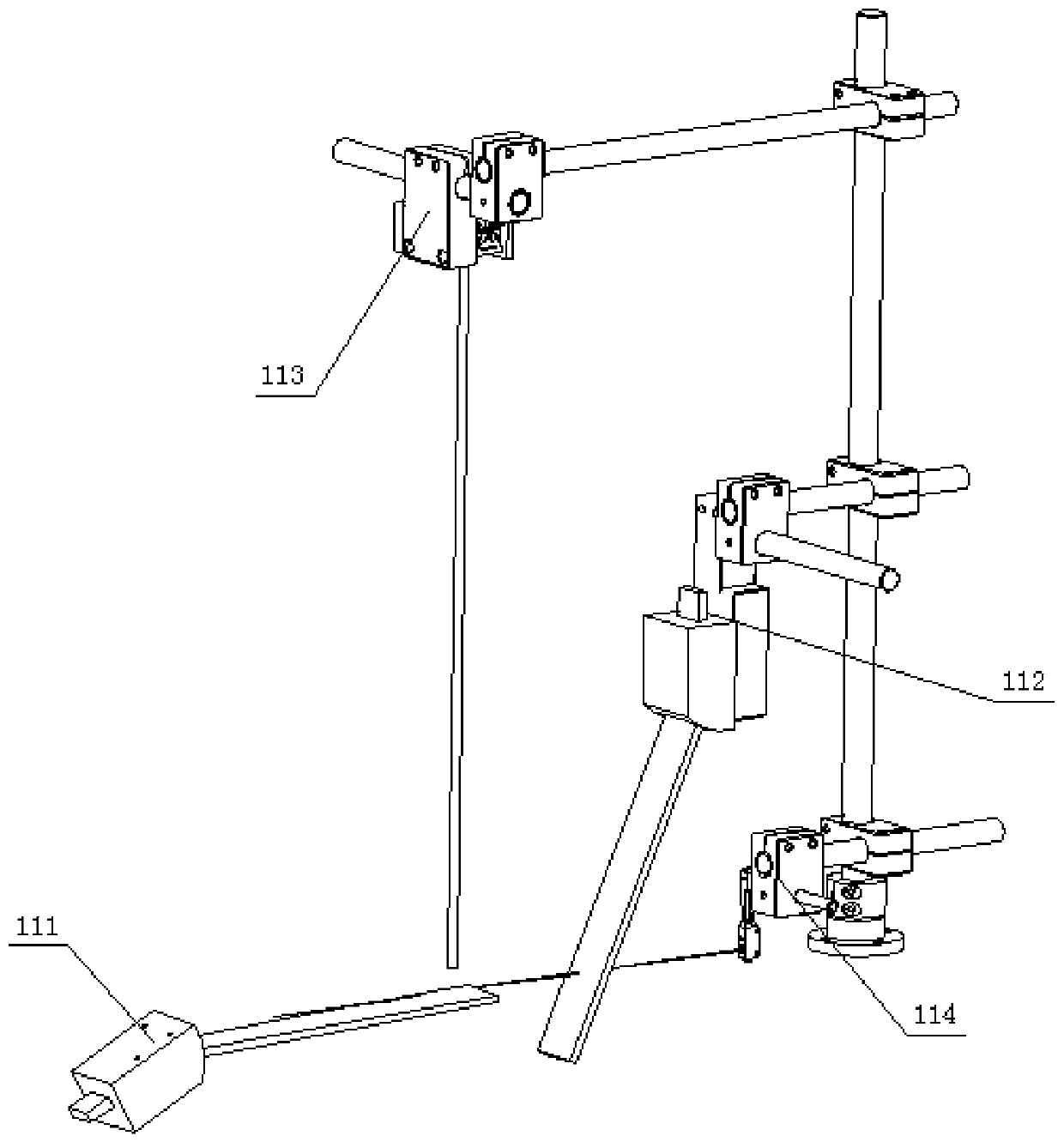

[0043]Among them, a scanning and detecting mechanism 11 is provided corresponding to the feeding and detecting station, and the scanning and detecting mechanism includes a scanning gun for scanning the two-dimensional code or barcode pasted o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com