Preparation technology of ceramic engravings

A preparation process, a technology of ceramics, applied in the field of preparation of ceramic prints, can solve the problems of only having a flat effect, fading or erosion of ceramic prints, and destroying the effect of a flat screen, etc., to achieve rich color patterns, good three-dimensionality and aesthetics, Increased aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

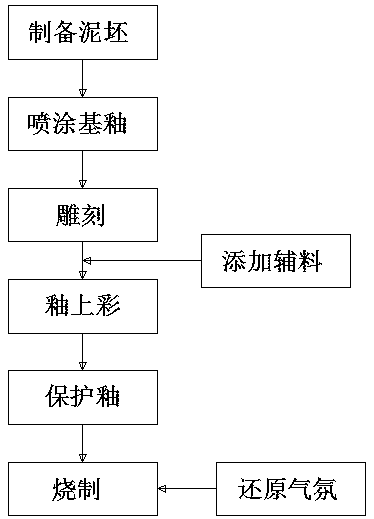

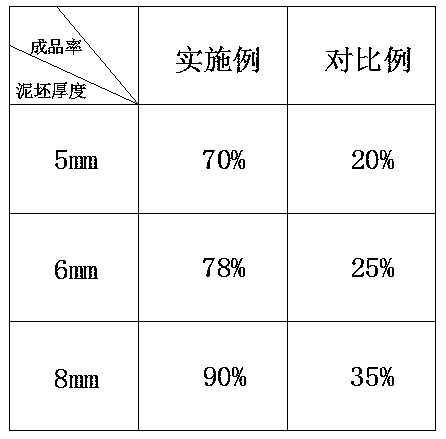

[0038] Example one, as figure 1 As shown, a preparation process of a ceramic print, comprising the following steps:

[0039] Preparation of mud blank: use ceramic wet mud to prepare mud plate, control the thickness of mud plate to be 5mm, then cut it into corresponding size, carry out bisque firing, and control the bisque firing temperature to be 950 ℃-1000 ℃, so that its moisture content is 8%;

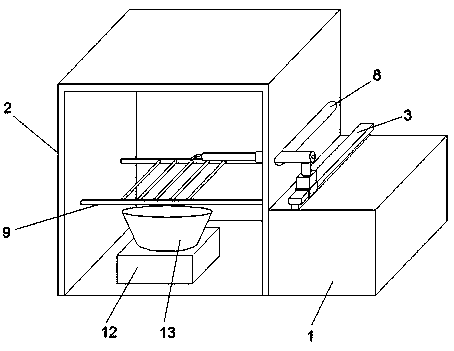

[0040] Spraying base glaze: spray a layer of base glaze on the bisque-fired mud body through a spraying device;

[0041] Engraving: Carve on the base glaze layer and clay body to form a corresponding three-dimensional pattern;

[0042] Overglaze color: spray one or more high-temperature color glazes corresponding to the engraved three-dimensional pattern, the high-temperature color glaze is an oxidation glaze, and a transparent glaze layer is sprayed on the high-temperature color glaze;

[0043] Protective glaze: A high temperature crystalline glaze layer is sprayed on the unpatte...

Embodiment 2

[0054] Embodiment two, a kind of preparation technology of ceramic print, comprises the following steps:

[0055] Preparation of clay billets: Use ceramic wet mud to prepare clay panels, control the thickness of the clay panels to 6mm, cut them into corresponding sizes, and carry out biscuit firing, and control the biscuit firing temperature at 950°C-1000°C so that the moisture content is 8%;

[0056] Spray base glaze: Spray a layer of base glaze on the bisque-fired mud body through a spraying device;

[0057] Carving: Carve on the basic glaze layer and mud base to form corresponding three-dimensional patterns;

[0058] On-glaze color: Spray one or more corresponding high-temperature color glazes on the engraved three-dimensional pattern, the high-temperature color glazes are oxidized glazes, and spray a transparent glaze layer on the high-temperature color glazes;

[0059] Protective glaze: a high-temperature crystalline glaze layer is sprayed on the pattern-free area above...

Embodiment 3

[0070] Embodiment three, a kind of preparation technology of ceramic print, comprises the following steps:

[0071] Preparation of clay billets: use ceramic wet mud to prepare clay panels, control the thickness of the clay panels to 8mm, then cut them into corresponding sizes, and perform biscuit firing, and control the biscuit firing temperature at 950°C-1000°C so that the moisture content is 8%;

[0072] Spray base glaze: Spray a layer of base glaze on the bisque-fired mud body through a spraying device;

[0073] Carving: Carve on the basic glaze layer and mud base to form corresponding three-dimensional patterns;

[0074] On-glaze color: Spray one or more corresponding high-temperature color glazes on the engraved three-dimensional pattern, the high-temperature color glazes are oxidized glazes, and spray a transparent glaze layer on the high-temperature color glazes;

[0075] Protective glaze: a high-temperature crystalline glaze layer is sprayed on the pattern-free area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com