Dual-mode plasma igniter

A plasma and igniter technology, which is applied in the direction of machines/engines, jet propulsion devices, gas turbine devices, etc., can solve problems such as short life, electrode ablation, and narrow ignition range, so as to improve reactivity, prevent cathode ablation, The effect of prolonging the life of the cathode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: taking this as an example to further describe and illustrate the present application.

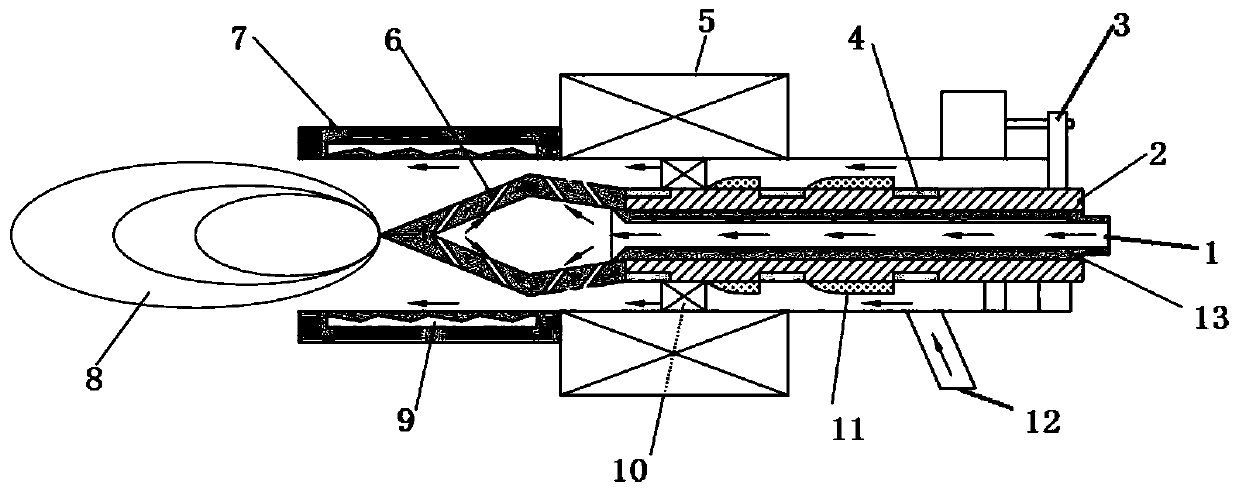

[0020] This embodiment provides a dual-mode plasma igniter, including: 1 anode, 1 replaceable cathode head, 1 hollow cathode connecting rod, 1 set of coils, 1 set of embedded anodes, 1 fixed bracket, and 1 insulating Layer, 1 cooling air inlet, 1 compressed air inlet, 1 cyclone, 1 water cooling tank. The anode is the first major component for achieving a thermally balanced plasma discharge, with a water-cooled tank inside for cooling; the replaceable cathode tip is the second component for achieving a thermally balanced plasma discharge, characterized in The surface is processed with cooling channels for gas circulation; the hollow cathode connecting rod is a hollow structure used to connect the replaceable cathode head and introduce cooling air into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com