Scanning type efficient purifying and return air collecting device

A gas collecting device and scanning technology, which is applied in the field of scanning high-efficiency purification and return air gas collecting device, can solve the problems of collecting and purifying outside, unable to meet special clean requirements, polluting the air, etc. The effect of shortening indoor cleaning time and protecting life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

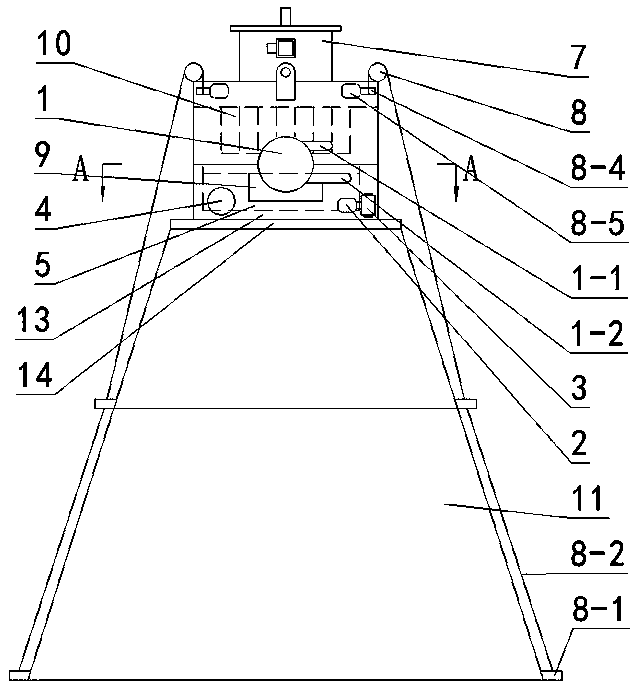

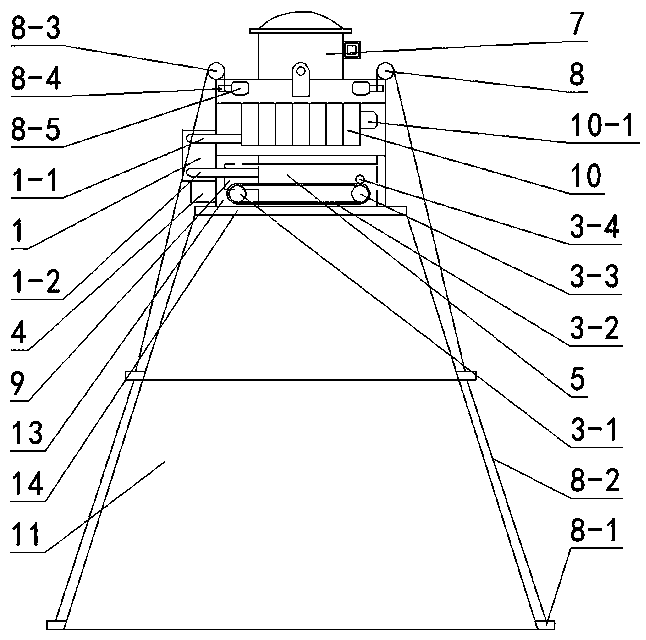

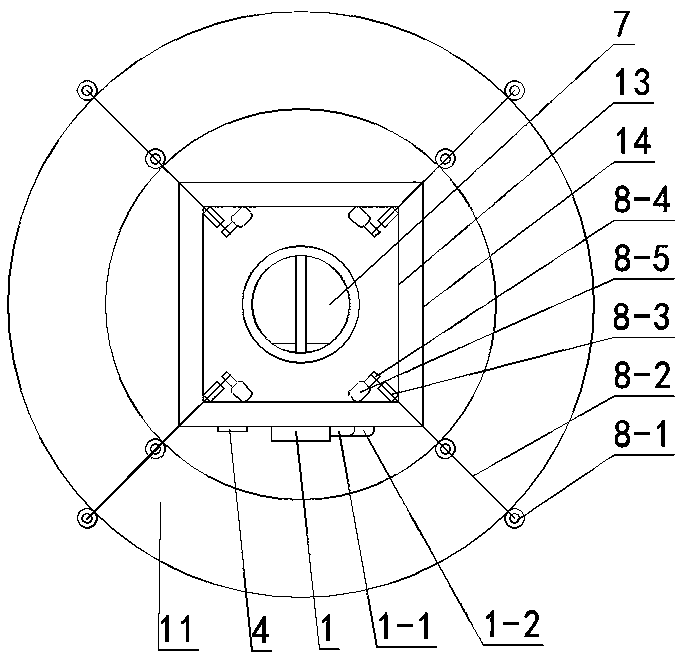

[0012] Embodiment 1: A scanning type high-efficiency purification return air collection device, which consists of a negative pressure gauge monitor (1); a scanning drive motor (2); a scanning mechanism (3); a leakage differential pressure device (4); device (5); sealing pressure plate (6); biosafety valve (7); gas collection hood lifting mechanism (8); monitoring and control device (9); centrifugal fan (10); gas collection hood (11); tuyere box (13); the chassis (14) is composed of an indoor scanning tuyere (12) in the middle of the chassis (14), and a sealing plate (6) is arranged around it, and the tuyere box (13) is a closed cube, which passes through the indoor scanning tuyere (12 ) is connected with the chassis (14), a round hole is set on the top of the tuyere box (13), the biosafety valve (7) is connected with the tuyere box (13) through the round hole, and the centrifugal fan (10) is fixed on the biosafety valve (7 ), the motor B (10-1) is fixed on the side, the air fi...

Embodiment 2

[0013]Embodiment 2: A scanning type high-efficiency purification return air collection device, which consists of a negative pressure gauge monitor (1); a scanning drive motor (2); a scanning mechanism (3); a leakage differential pressure device (4); device (5); sealing pressure plate (6); biosafety valve (7); gas collection hood lifting mechanism (8); monitoring and control device (9); centrifugal fan (10); gas collection hood (11); tuyere box (13); the chassis (14) is composed of an indoor scanning air outlet (12) in the middle of the chassis (14), and a sealing plate (6) is arranged around it, and the air outlet box (13) is a closed cuboid, and the indoor scanning air outlet (12) ) is connected with the chassis (14), a round hole is set on the top of the tuyere box (13), the biosafety valve (7) is connected with the tuyere box (13) through the round hole, and the centrifugal fan (10) is fixed on the biosafety valve (7 ), the motor B (10-1) is fixed on the side, the air filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com