Weighing principle based surface tension testing device and method of sandwich effect

A technology of surface tension and weighing principle, applied in surface tension analysis, measuring device, surface/boundary effect, etc., can solve the problem of low measurement accuracy, and achieve the effect of high measurement accuracy, convenient operation and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

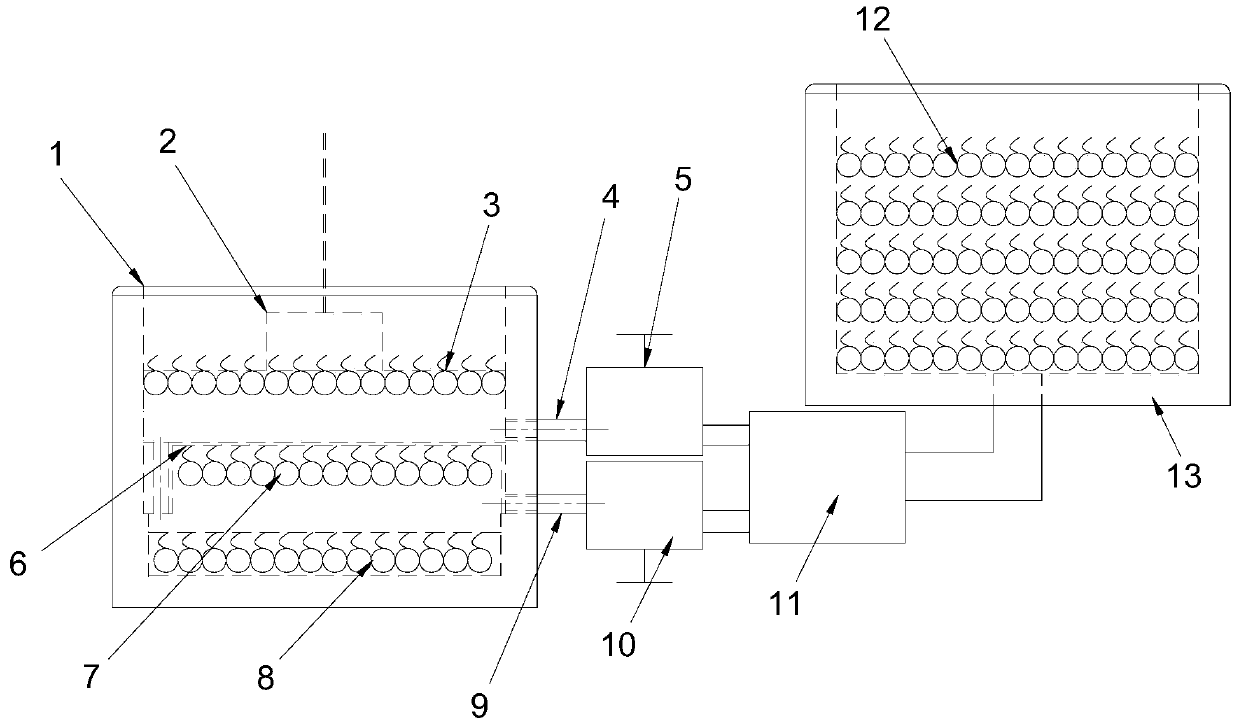

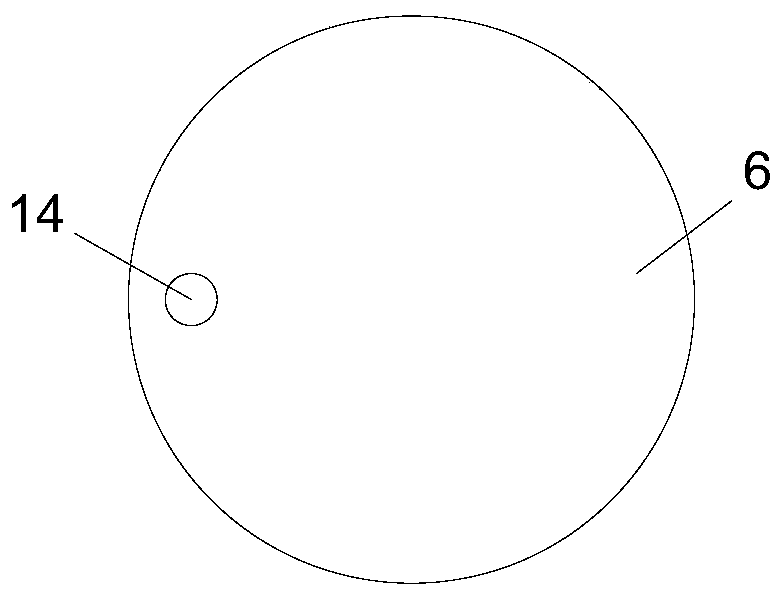

[0025] Such as figure 1 , figure 2 Shown, a kind of sandwich effect surface tension testing device based on weighing principle comprises test sample pool 1, test probe 2, layered sample pool 6, tee 11, liquid inlet pump and liquid storage tank 13, and described The layered sample pool 6 is arranged in the middle part of the test sample pool 1 to divide the test sample pool 1 into an upper accommodation area and a lower accommodation area, and the stratified sample pool 6 has a shunt pipe connecting the upper and lower accommodation areas in the test sample pool 1 14. The tee 11 communicates with the upper accommodation area of the test sample pool 1 through the upper liquid inlet pipe 4, and communicates with the lower accommodation area through the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com