Light emitting device, manufacturing method thereof, mask plate, display substrate and display device

A technology of light-emitting devices and manufacturing methods, which can be applied to semiconductor devices, electric solid-state devices, electrical components, etc., and can solve problems such as the influence of light-emitting layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

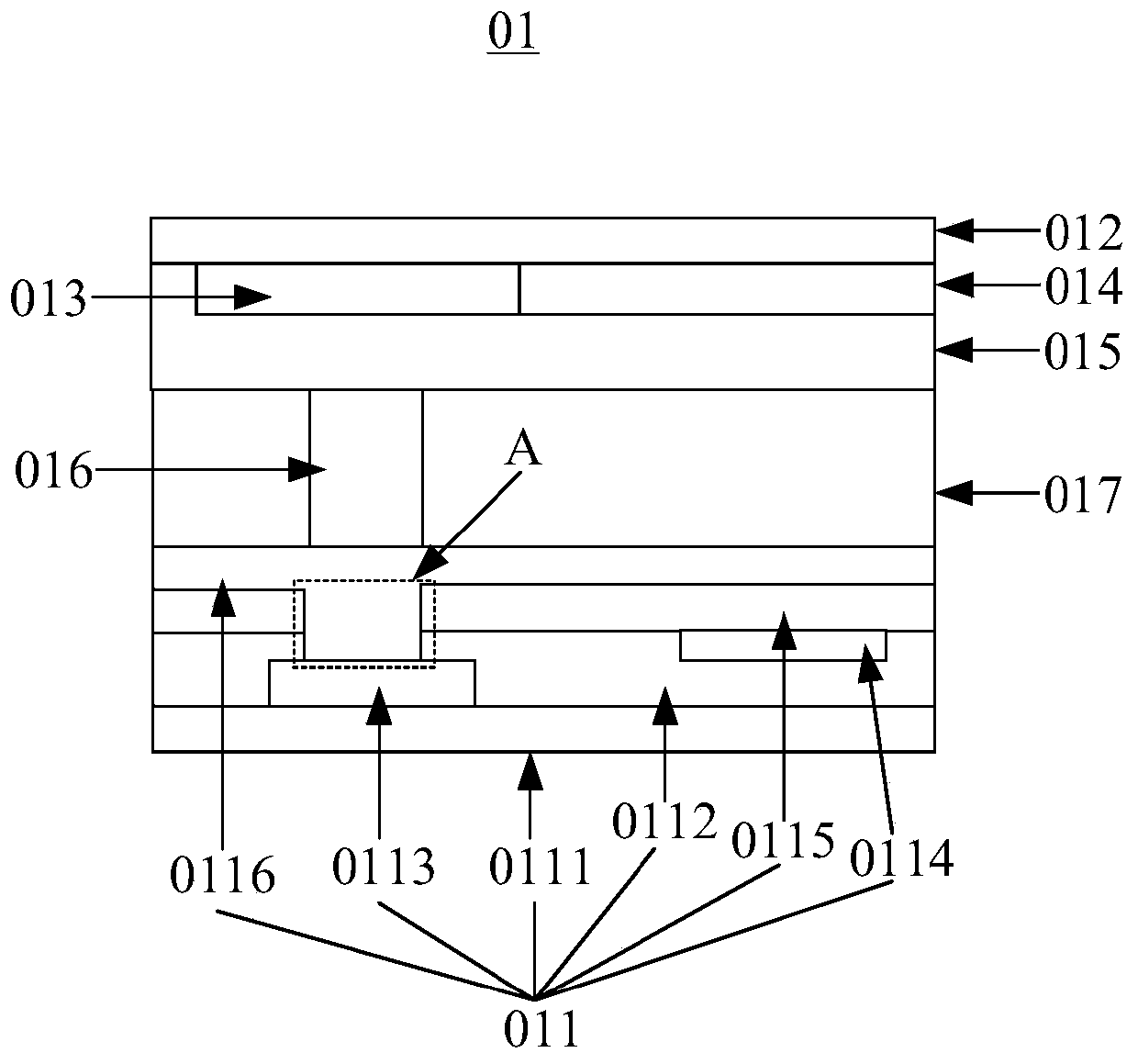

[0044] figure 1 A schematic structural diagram of an OLED display device in the related art is shown. Such as figure 1 As shown, the OLED display device 01 includes: a display substrate ( figure 1 Not marked in ), cover plate 012, black matrix 013, color filter 014, upper cover layer 015, support pillar 016, filling layer 017 and sealant ( figure 1 not shown).

[0045] Wherein, the display substrate includes a light-emitting device 011, and the light-emitting device 011 includes: a base substrate 0111, a control circuit layer 0112, an OLED and an auxiliary electrode 0113, and the OLED includes an anode 0114 and a light-emitting layer 0115 arranged in sequence along a direction away from the base substrate 0111. and cathode 01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com