Construction method of semiconductor quantum dot/graphene van der Waals junction flexible device

A quantum dot and semiconductor technology is applied in the construction of semiconductor quantum dot/graphene van der Waals junction thin-film flexible devices to achieve the effects of low cost, simple and controllable construction method and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

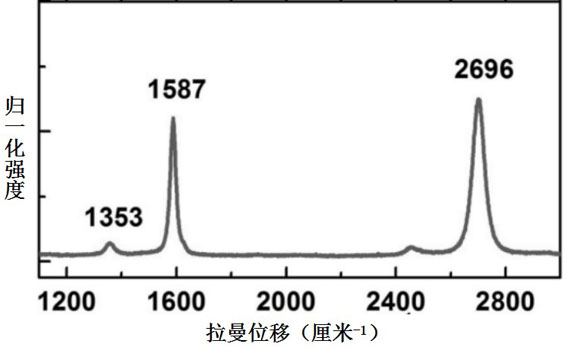

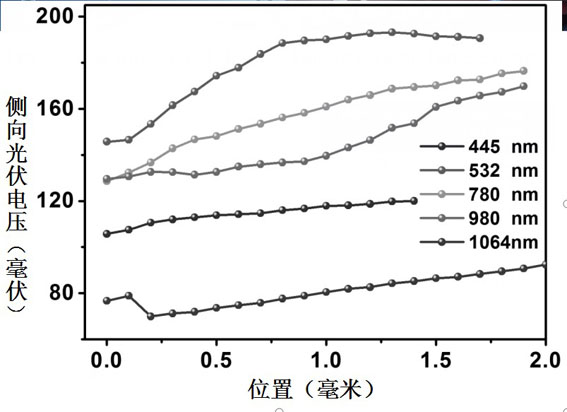

[0024] A method for constructing a semiconductor quantum dot / graphene van der Waals junction thin film flexible device with good surface photovoltaic performance, a method for preparing single-layer graphene by mechanical exfoliation chemical vapor deposition on a flexible substrate, and modifying the graphene Semiconductor quantum dots, control the device annealing temperature and time, optimize the van der Waals contact between semiconductor quantum dots and graphene, and successfully construct a semiconductor quantum dot / graphene van der Waals junction thin film flexible surface with ideal surface photovoltaic response performance For photovoltaic devices, follow the steps below:

[0025] 1) Wet-transfer the single-layer graphene sample prepared by chemical vapor deposition onto special paper, place it on a hot plate at 30°C for 60s, and obtain a single-layer graphene sample with special paper substrate;

[0026] 2) Paste the pressure-sensitive tape on the single-layer grap...

Embodiment 2

[0030] A semiconductor quantum dot / graphene van der Waals junction film flexible device with good surface photovoltaic performance is constructed according to the following steps:

[0031] 1) Wet-transfer the single-layer graphene sample prepared by chemical vapor deposition onto special paper, place it on a hot plate at 30°C for 60s, and obtain a single-layer graphene sample with special paper substrate;

[0032] 2) Paste the pressure-sensitive tape on the single-layer graphene film whose substrate is special paper, and apply appropriate pressure to the pressure-sensitive tape, so that the pressure-sensitive tape and the graphene covered by it are firmly bonded;

[0033] 3) Peel off the pressure-sensitive tape firmly combined with graphene from the special paper to obtain a single-layer graphene sample on a flexible substrate;

[0034] 4) MoS 2 Quantum dots are deposited in situ on the single-layer graphene film sample on the flexible substrate by chemical vapor deposition, ...

Embodiment 3

[0036] A semiconductor quantum dot / graphene van der Waals junction film flexible device with good surface photovoltaic performance is constructed according to the following steps:

[0037] 1) Wet-transfer the single-layer graphene sample prepared by chemical vapor deposition onto special paper, place it on a hot plate at 30°C for 60s, and obtain a single-layer graphene sample with special paper substrate;

[0038] 2) Paste the pressure-sensitive tape on the single-layer graphene film whose substrate is special paper, and apply appropriate pressure to the pressure-sensitive tape, so that the pressure-sensitive tape and the graphene covered by it are firmly bonded;

[0039] 3) Peel off the pressure-sensitive tape firmly combined with graphene from the special paper to obtain a single-layer graphene sample on a flexible substrate;

[0040] 4) MoS 2Quantum dots are in-situ deposited on the single-layer graphene thin film sample on the flexible substrate by atomic layer deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com