PLC automatic control-based polishing equipment with multi-station circulating machining function

A technology of automatic control and cyclic processing, applied in metal processing equipment, grinding/polishing equipment, automatic grinding control devices, etc. Improve workpiece polishing efficiency, improve workpiece polishing efficiency, improve polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

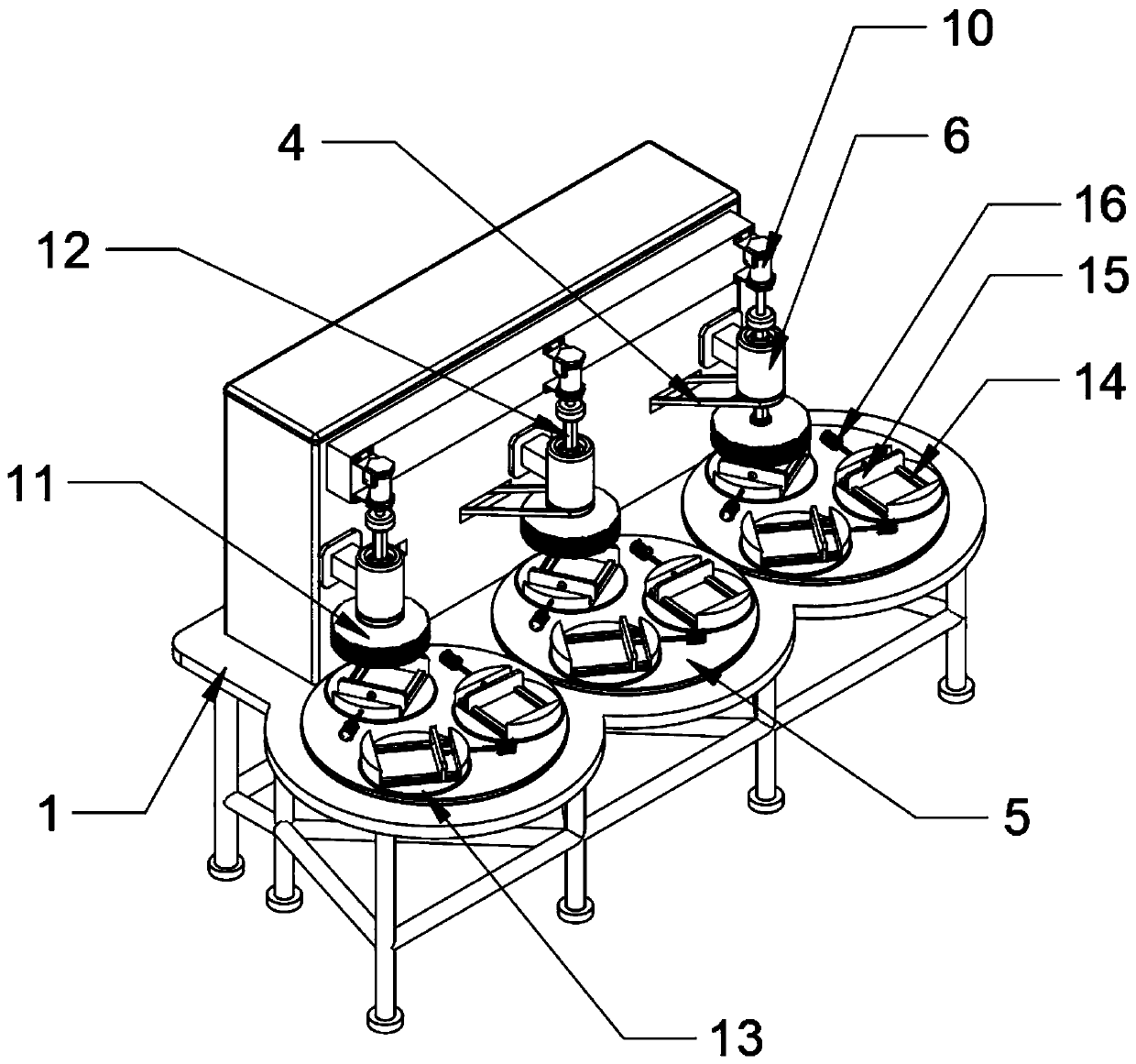

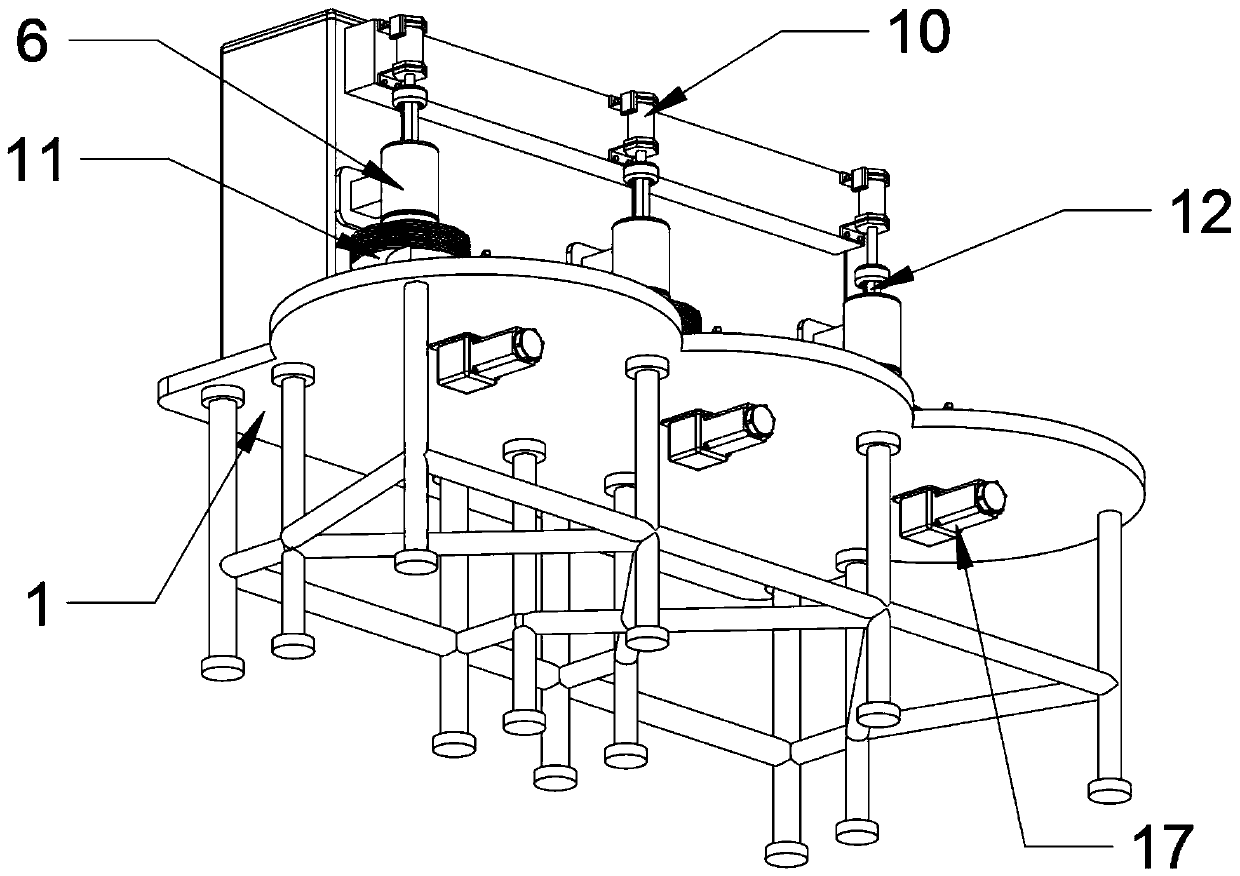

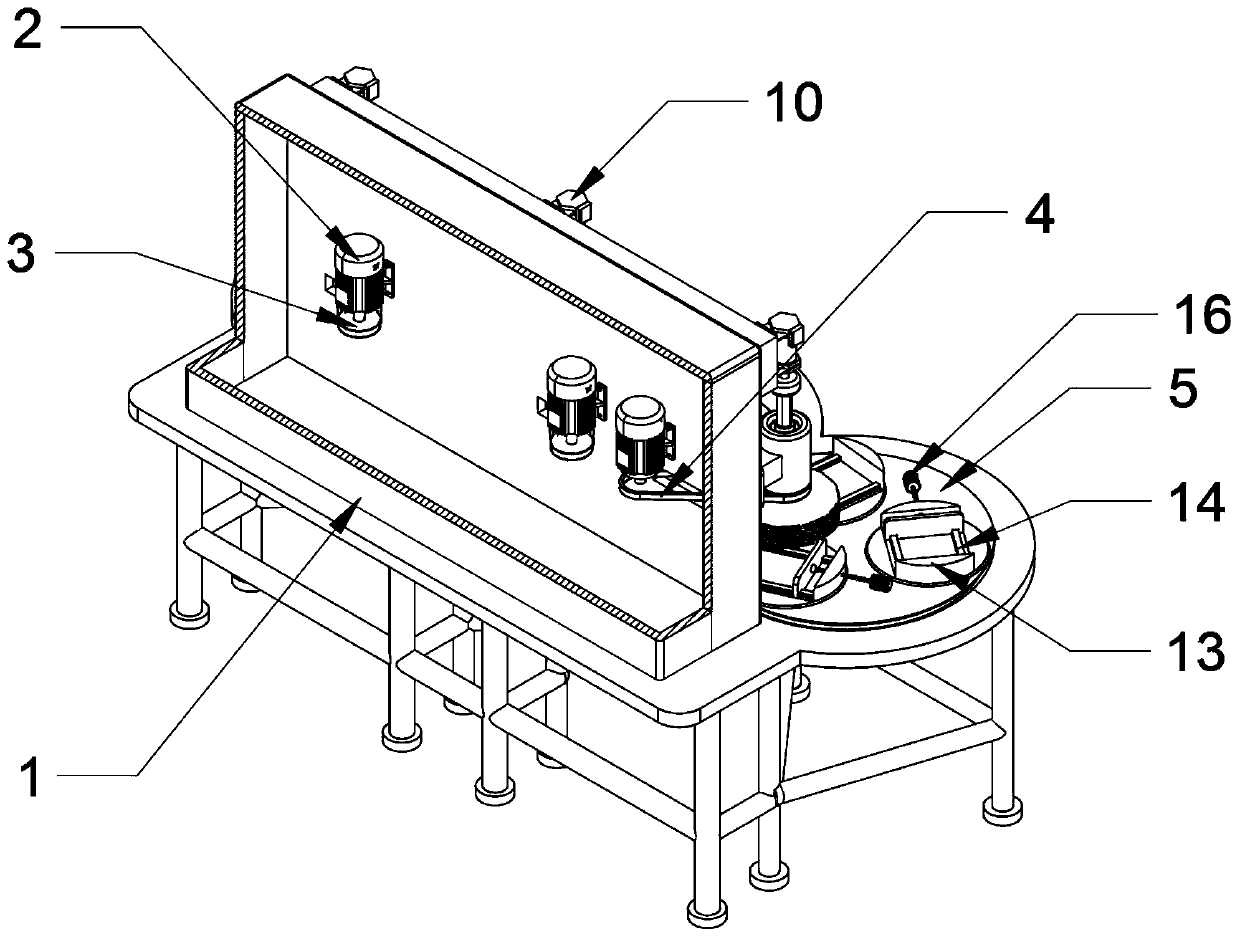

[0035] as attached figure 1 to attach Figure 11 Shown:

[0036]The present invention provides a polishing equipment based on PLC automatic control for multi-station cycle processing, which includes a main body 1, a driving motor 2, a driving wheel 3, a transmission belt 4, a main turntable 5, a positioning cylinder 6, a positioning bearing 7, and a main shaft 8. Planar bearing 9, electric cylinder 10, polishing disc 11, hexagonal shaft 12, workpiece clamping disc 13, slideway 14, clamp block 15, bolt shaft 16 and rotating motor 17; the top of the main body 1 is hollow, and the main body 1. The front end of the top is a circular plate-shaped structure; there are three driving motors 2, and the three driving motors 2 are installed in the top of the main body 1 through bolts, and the driving motor 2 is connected to the PLC automation control equipment through the power line; A driving wheel 3 is installed at the bottom of the drive motor 2, and the driving wheel 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com