Brick preparation method and device

A brick body and system technology, applied in the field of building material preparation, can solve problems such as difficulty in controlling progress and potential safety hazards, and achieve the effects of reducing potential safety hazards, improving quality, and reducing proportioning errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

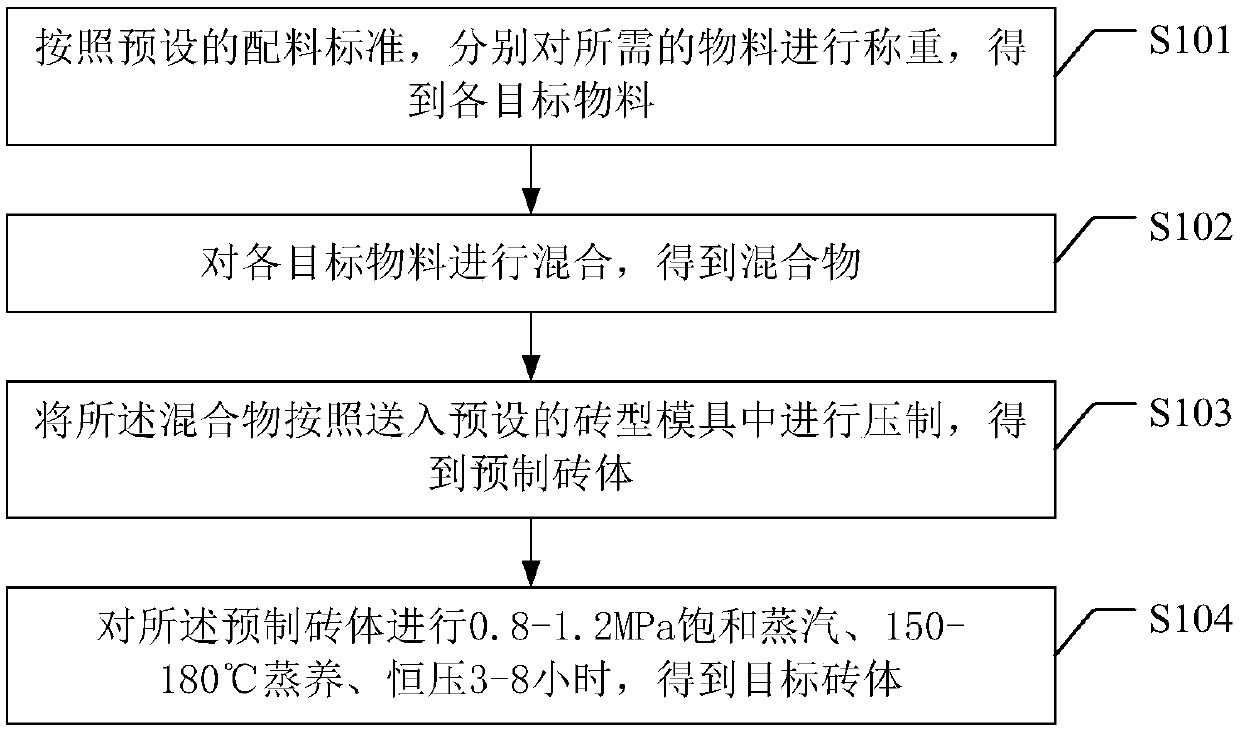

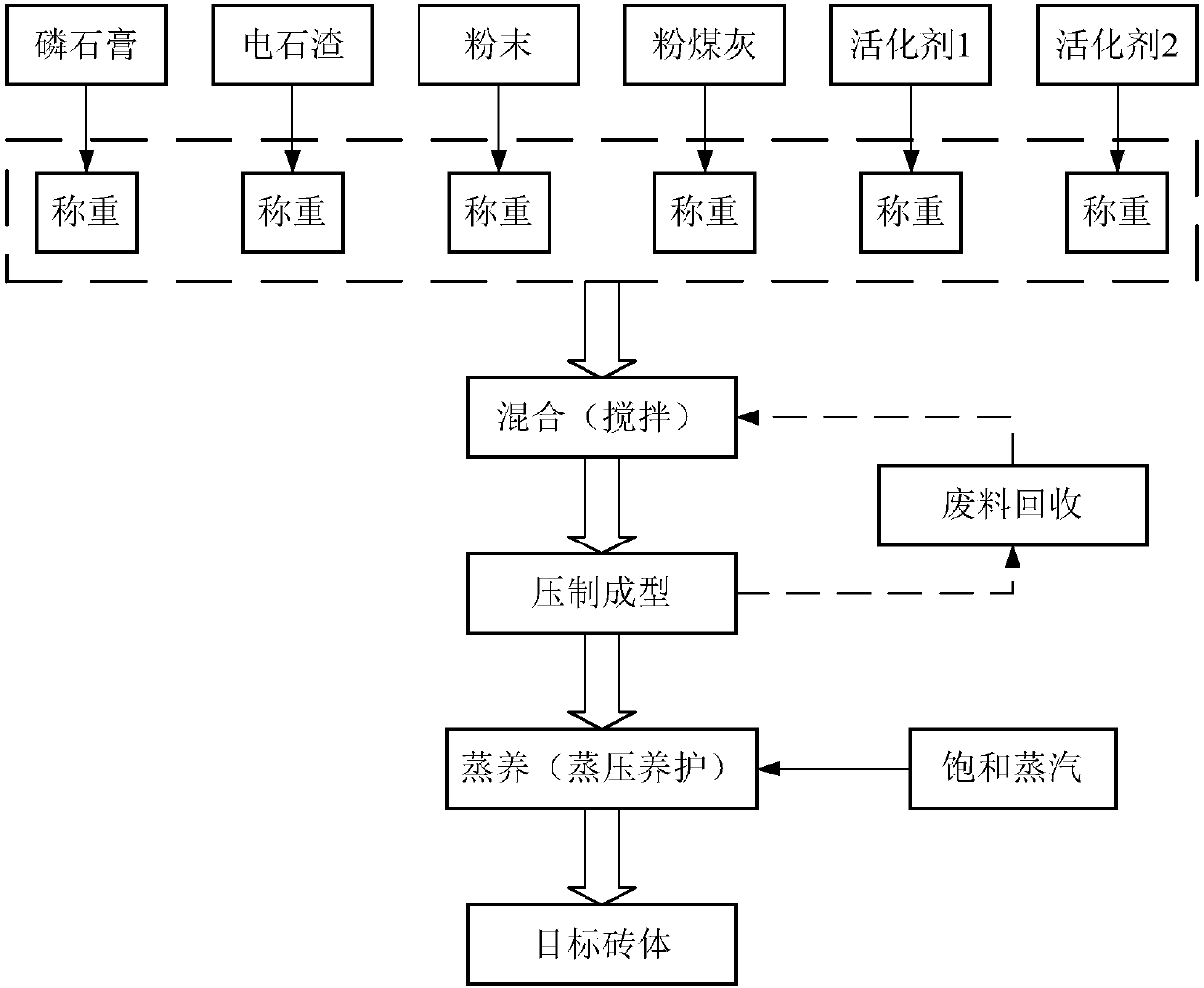

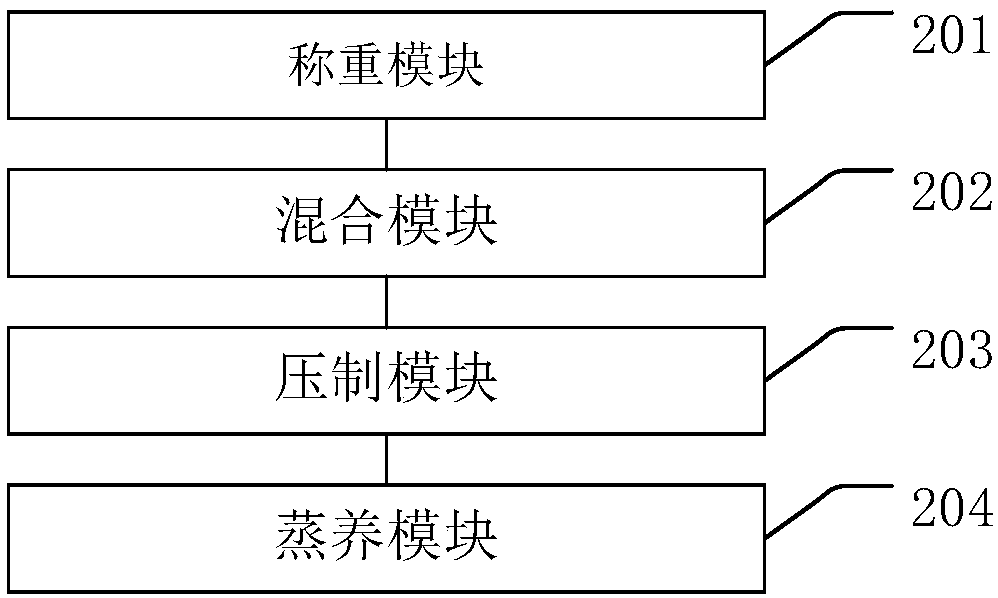

[0031] Such as figure 1 Shown, a kind of specific structural representation of the composite porous brick provided by the present invention; The method comprises steps:

[0032] S101: According to the preset ingredient standard, weigh the required materials respectively to obtain each target material;

[0033] In a specific implementation mode provided by the embodiments of the present invention, the materials required for the prepared brick body include at least: carbide slag, phosphogypsum, calcium oxide and magnesium oxide.

[0034] Furthermore, the total amount of the calcium oxide and the magnesium oxide contained in the above-mentioned required materials is not less than 75% of the total amount of the target materials.

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com