Raw coal proportioning control system and method with security warning function

A technology of ratio control and safety reminder, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as lack of management, artificial ratio errors, and changes in the quality of raw coal for washing, so as to achieve realization and operation Convenient, easy to use and operate, and reduce the effect of proportioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

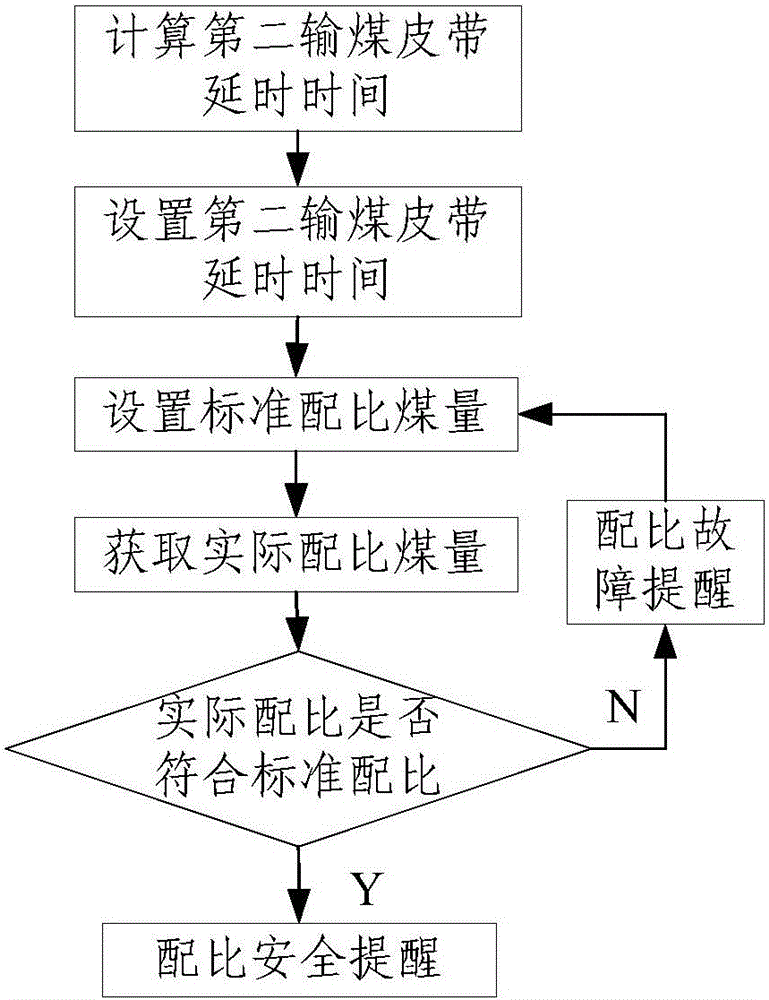

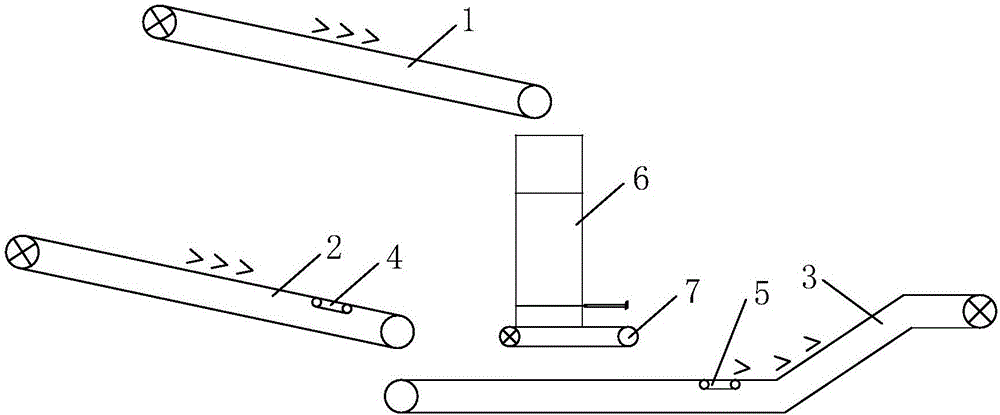

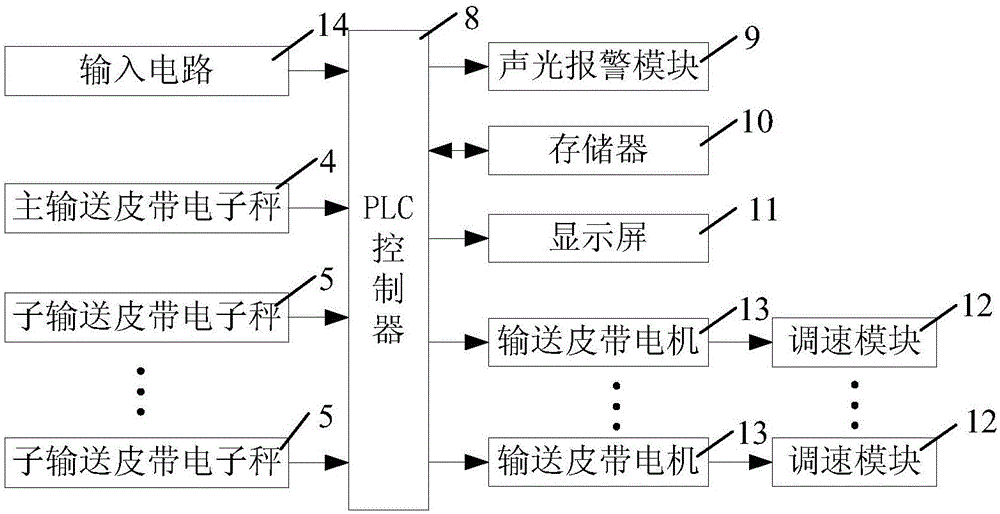

[0040] Such as figure 2 and image 3As shown, the present invention includes a proportioning device and a control device. The proportioning device includes a sub-conveyor belt for transporting raw coal mined from different coal seams and a main conveyor belt 3 for transporting proportioned raw coal. The conveyor belt includes a first coal conveyor belt 1 and a second coal conveyor belt 2, and the output port of the first coal conveyor belt 1 and the output port of the second coal conveyor belt 2 are all located above the main conveyor belt 3, so The control device includes a PLC controller 8 and a speed regulation module 12 connected with the second coal conveying belt 2, the input of the PLC controller 8 is connected with an input circuit 14, a main conveying belt for collecting the total amount of coal conveyed Electronic scale 4 and the sub-coal conveying belt electronic scale 5 for collecting the amount of coal conveyed by the second coal conveying belt 2, the output ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com