Building basement top slab settlement joint plugging structure and construction method thereof

A basement roof and construction method technology, which is applied to underwater structures, infrastructure engineering, construction, etc., can solve the problem of water leakage in settlement joint sealing structures, and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

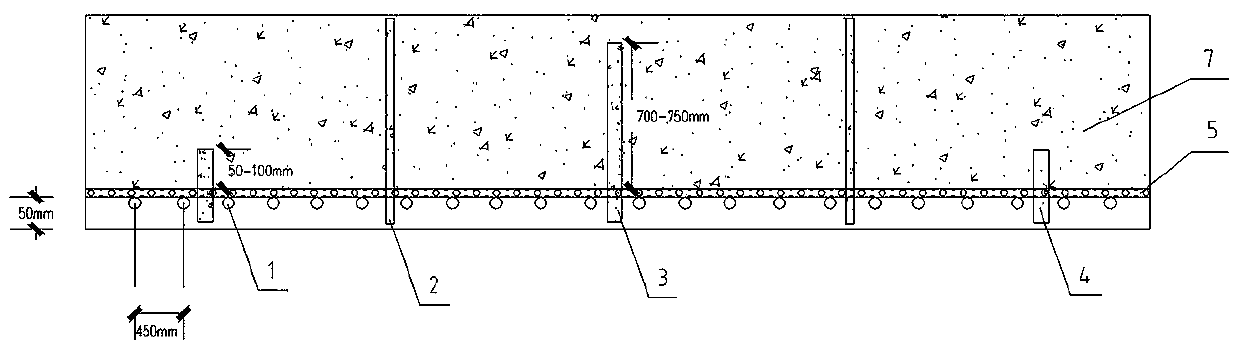

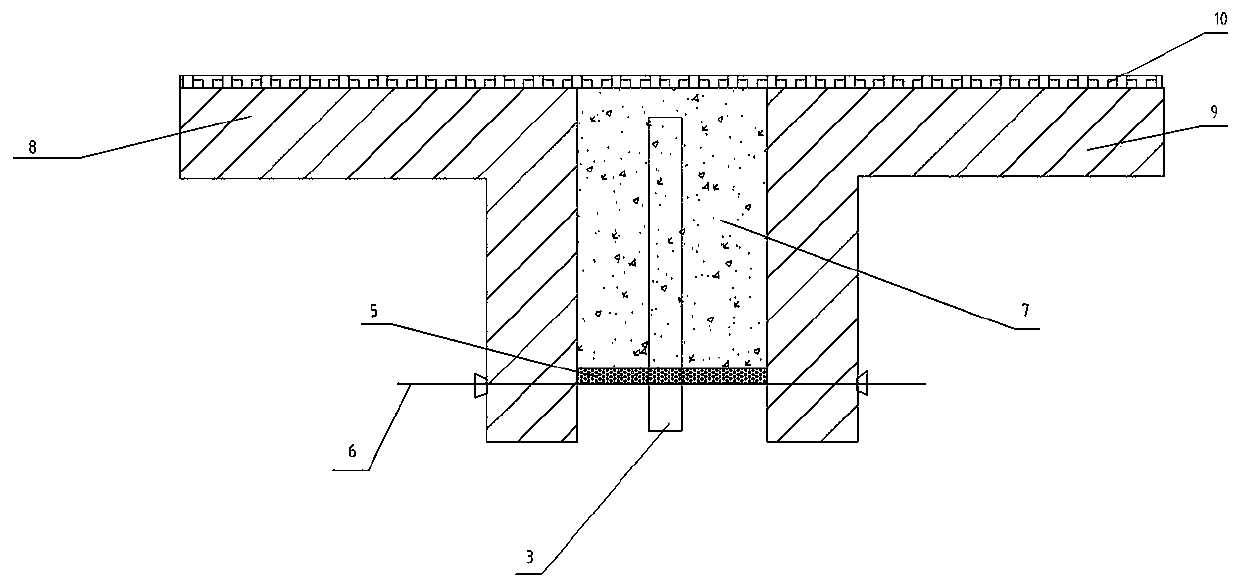

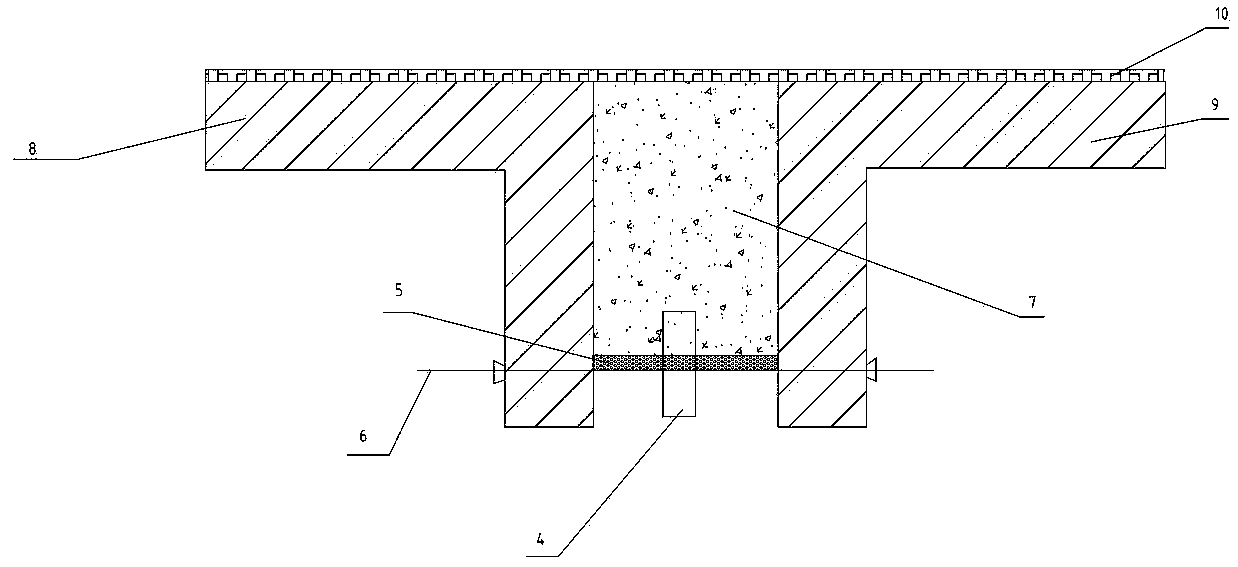

[0067] Such as figure 1 It shows the settlement joint sealing structure of the building basement roof provided by the present invention, and the sealing structure includes: a support 6 , a supporting member 5 , a grouting pipe and an exhaust pipe 2 .

[0068]Among them, the brackets are arranged at the settlement joints between the beams, and the support member 5 is arranged on the supports 6 to form a settlement joint sealing cavity 7 with the beams and the top plate 10, and the grouting pipe and the exhaust pipe 2 both pass through the support members 5 is arranged at the settlement joint sealing cavity 7, so that the problem of water leakage in the settlement joint of the basement roof can be prevented and the sealing performance of the settlement joint sealing cavity can be improved.

[0069] In this example, if figure 1 , clean up all the debris in the settlement joint, the dirt, ash, and debris on both sides of the base of the settlement joint, rinse with water and dry ...

Embodiment 2

[0073] The construction method for sealing the settlement joints of the roof of the building basement provided by the present invention comprises the following steps: the support 6 is arranged at the settlement joint on the beam, and the supporting member 5 is arranged on the support 6 to be connected with the beam and the beam. The top plate 10 forms a settlement joint sealing cavity 7, the grouting pipe and the exhaust pipe 2 are respectively passed through the supporting member 5 and placed at the settlement joint sealing cavity 7, and the bottom of the grouting pipe and the exhaust pipe 2 are sealed with a sealing material. For sealing, the settlement joint sealing cavity 7 is filled with leakage plugging material, and the settlement joint sealing cavity 7 is coated with an epoxy resin protective layer.

[0074] Further, corresponding through holes 1 are drilled on the first beam 8 and the second beam 9 separated by the settlement joint, and the brackets 6 are respectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com