Exhaust valve, compressor and pump driving loop heat pipe

A technology of exhaust valves and exhaust holes, which is applied in the direction of machines/engines, pump components, mechanical equipment, etc., can solve the problems of reduced energy-saving effect in the working mode of pump-driven heat pipes, achieve energy efficiency and improve operation stability, and improve operation Reliability, the effect of avoiding overcompression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the drawings and embodiments.

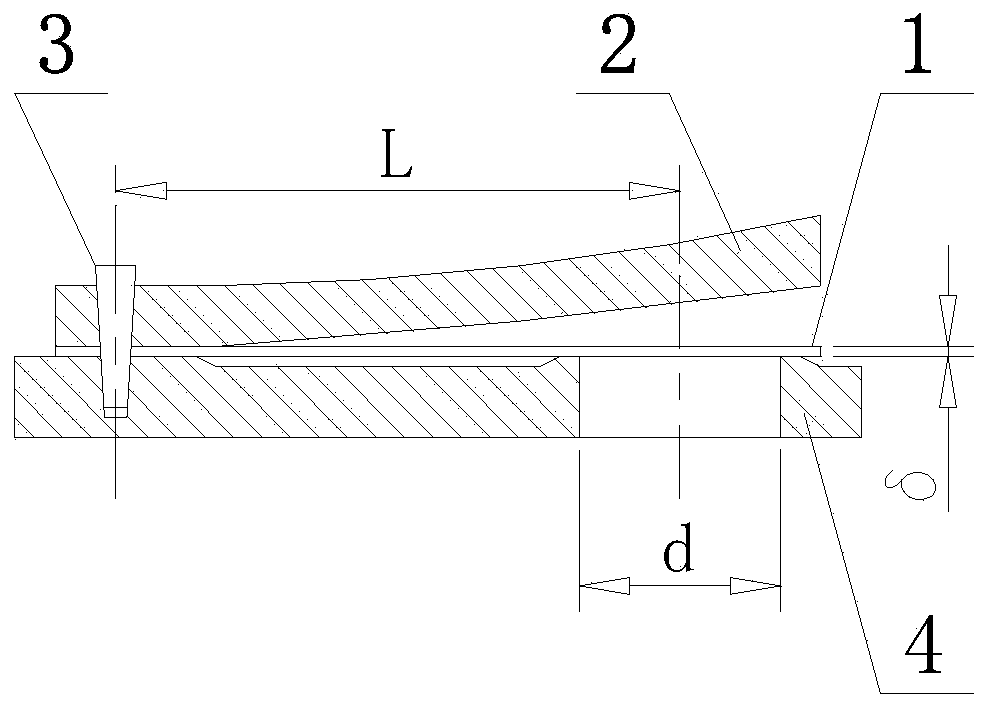

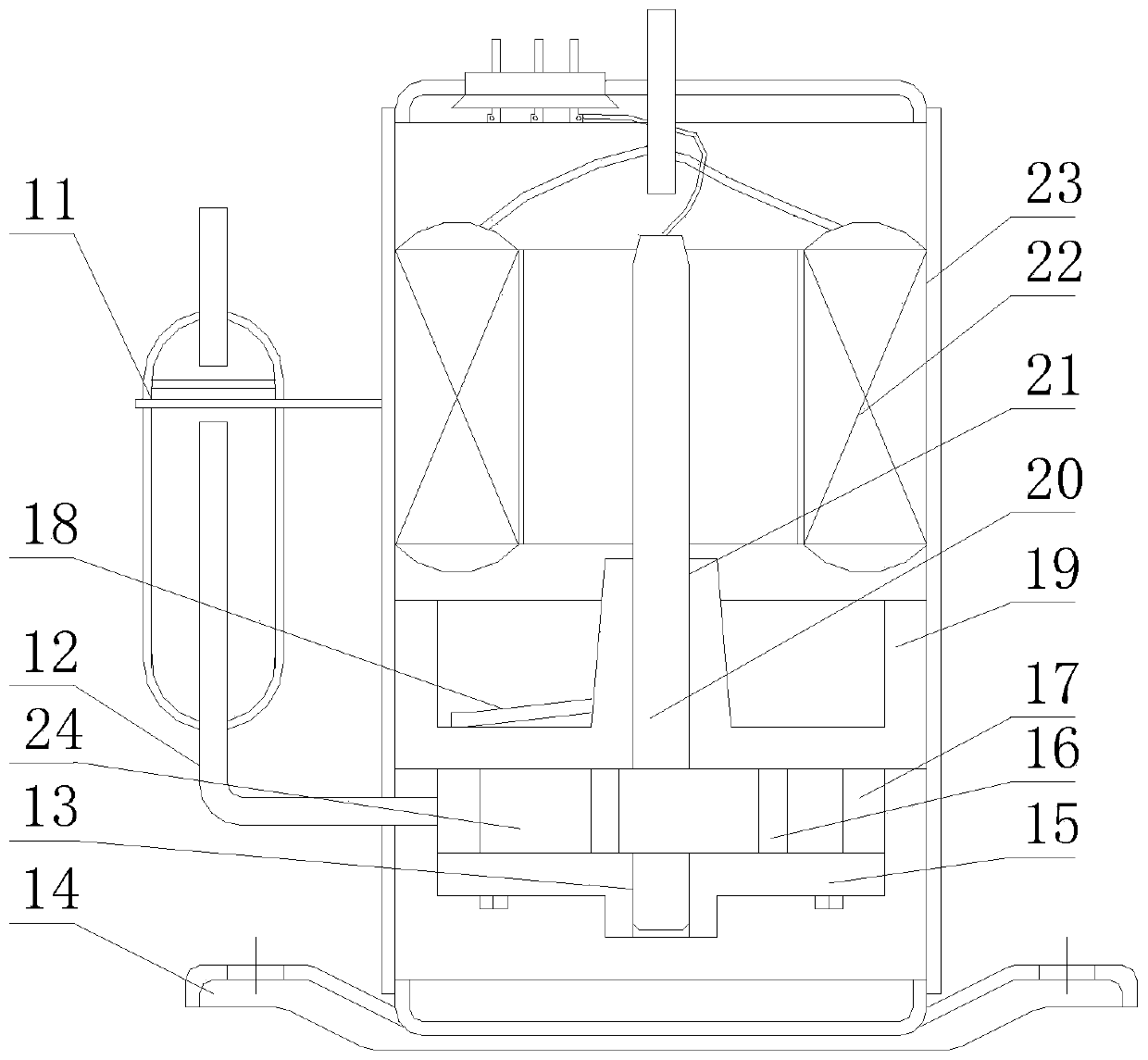

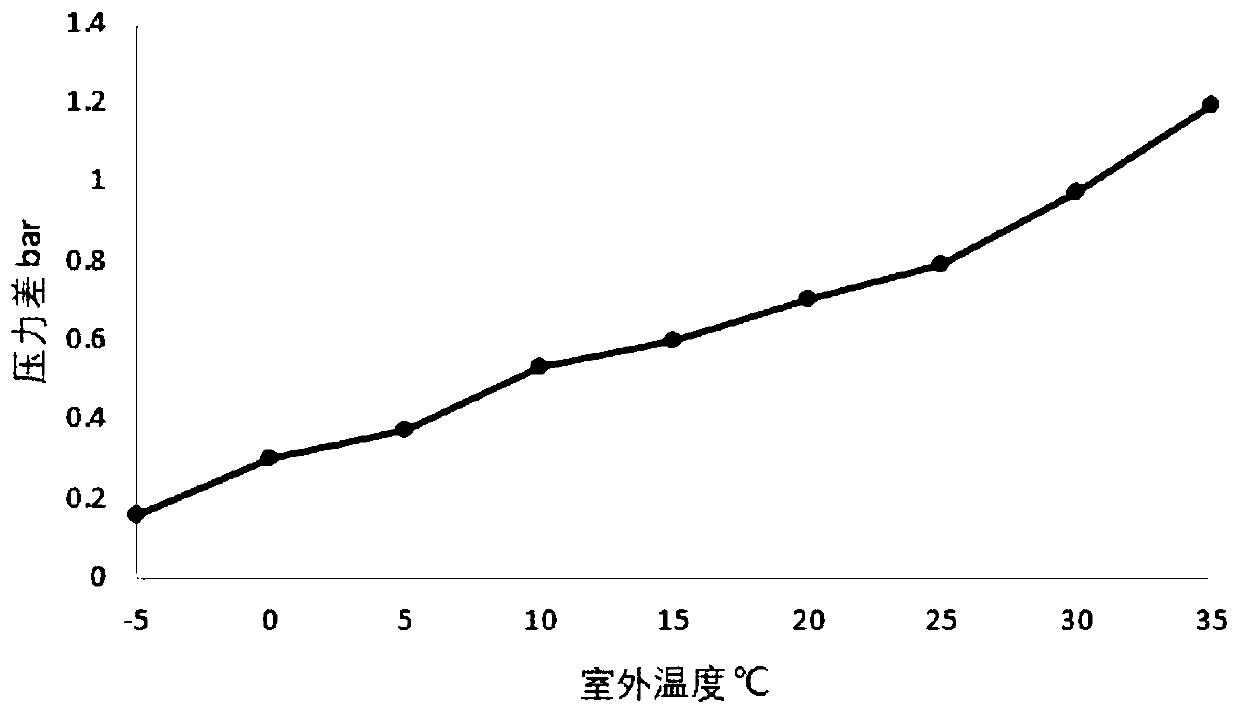

[0029] reference figure 1 The exhaust valve includes a valve plate (1), a limit plate (2), a screw (3), a support (4), etc. The valve plate (4) is provided with an exhaust hole with a diameter of d, and the support (4) The upper end cover (19) of the compressor, the upper end cover (19) has screw (3) mounting holes, the distance between the exhaust hole and the mounting hole is L, the valve plate (1) is an elastic flat plate, and its thickness is δ, the mounting end of the valve disc (1) and the limit plate (2) has a through hole for the screw (3) to pass through. The limit plate (2) is flat near the through hole, and the other end is warped upward, And the relationship between δ and d is: 0.010≤δ / d Figure 5 It is a graph of the change between the compressor energy efficiency ratio (COP) and δ / d of the present invention; when assembling, one end of the valve plate (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com