Digital twinning technology-based jacquard sliding bearing monitoring system and method

A sliding bearing and monitoring system technology, applied in mechanical bearing testing, mechanical component testing, electrical digital data processing, etc., can solve the problems of abrasive wear, gluing and fatigue pitting, low normal service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

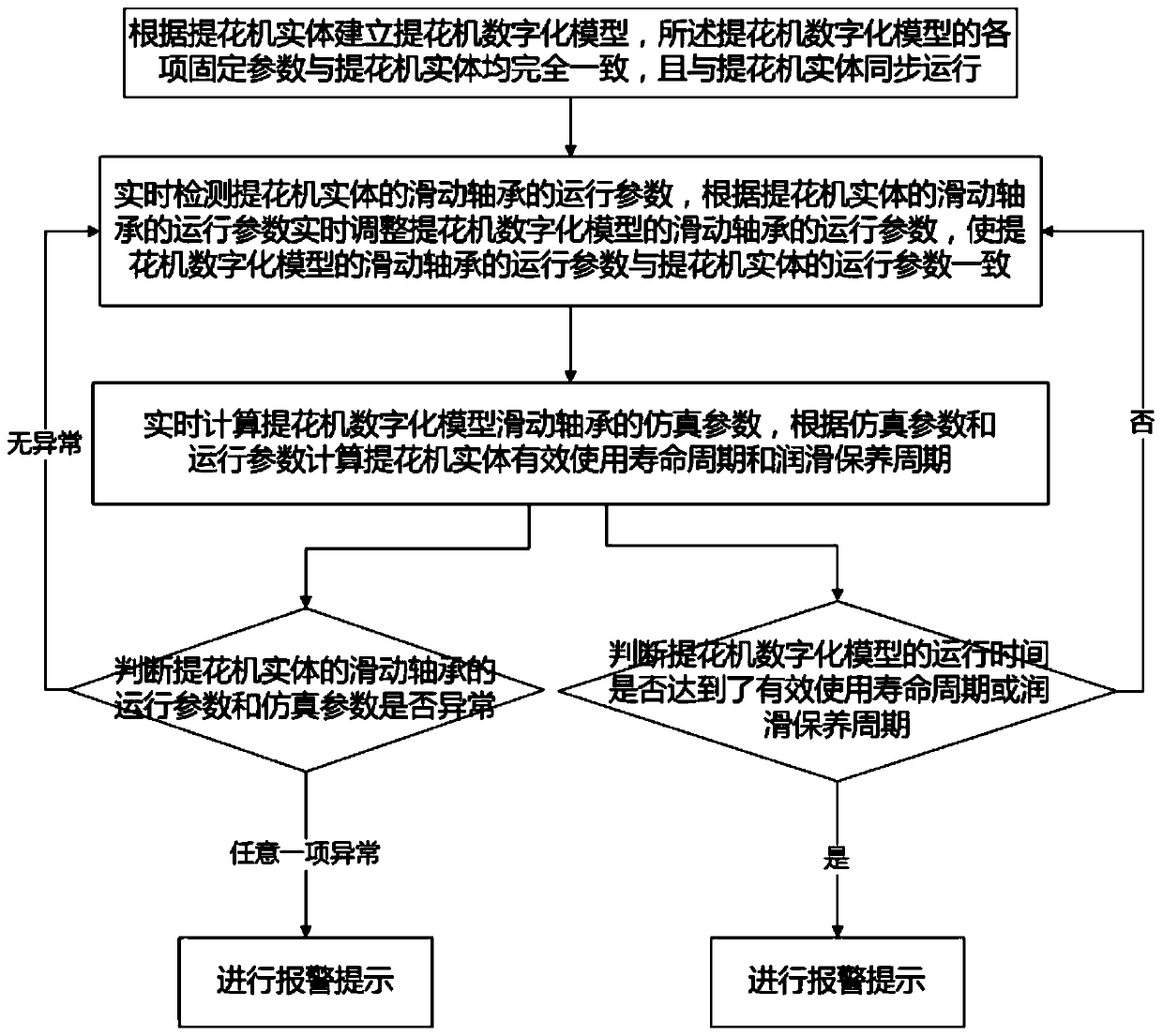

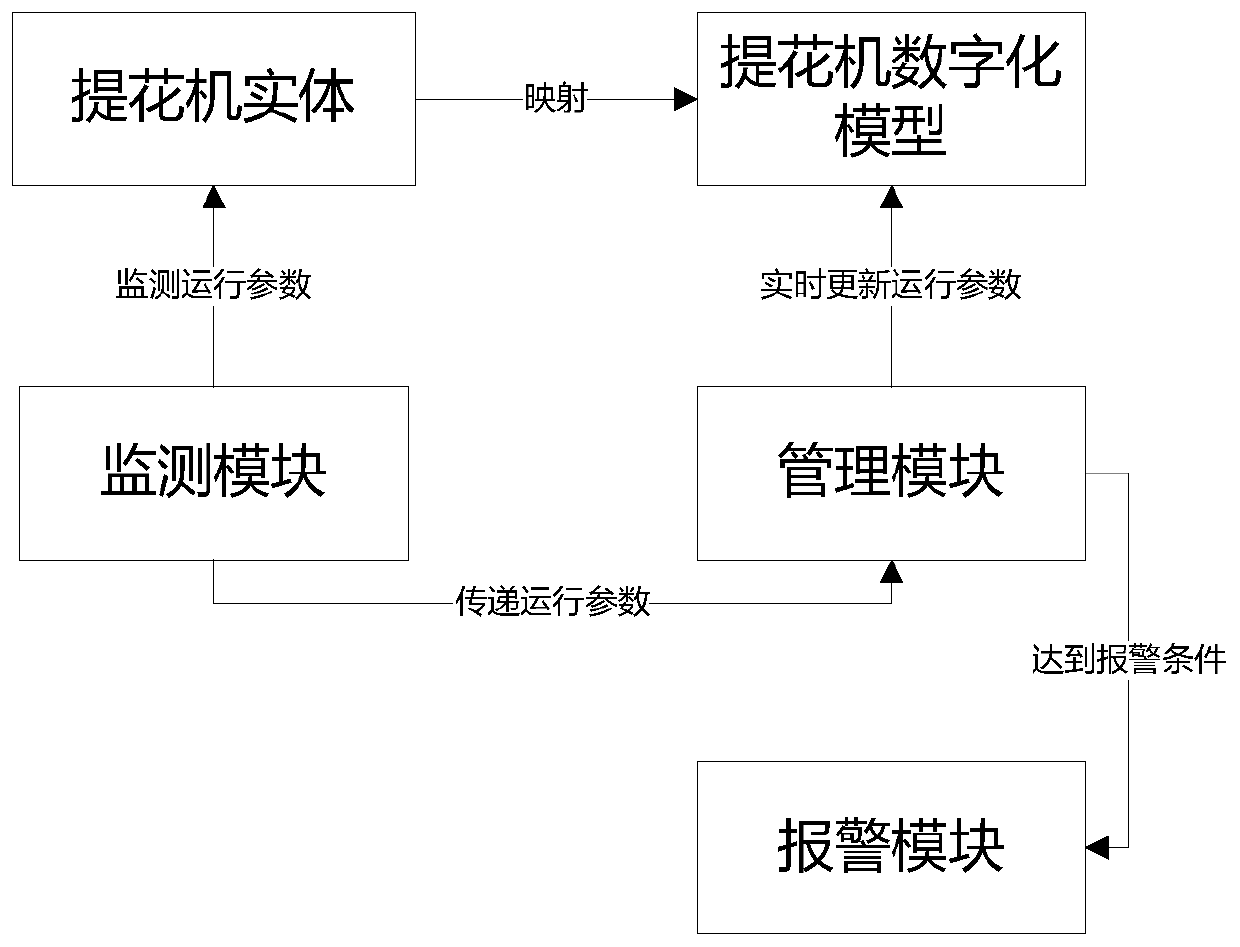

[0027] A method for monitoring sliding bearings of jacquard machines based on digital twin technology, comprising the following steps:

[0028] Step 1. Establish the jacquard machine digital model according to the jacquard machine entity. The fixed parameters of the jacquard machine digital model are completely consistent with the jacquard machine entity, and run synchronously with the jacquard machine entity;

[0029] Step 2, detect in real time the operating parameters of the sliding bearing of the jacquard machine entity, adjust the operating parameters of the sliding bearing of the jacquard machine digital model in real time according to the operating parameters of the jacquard machine entity sliding bearing, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com