Indoor tire slippery performance testing method

A technology of wet skid performance and test method, which is applied in the direction of automobile tire test, vehicle test, machine/structural component test, etc. problems, to achieve the effect of improving test efficiency, reducing test costs, and reducing experimental cycle and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

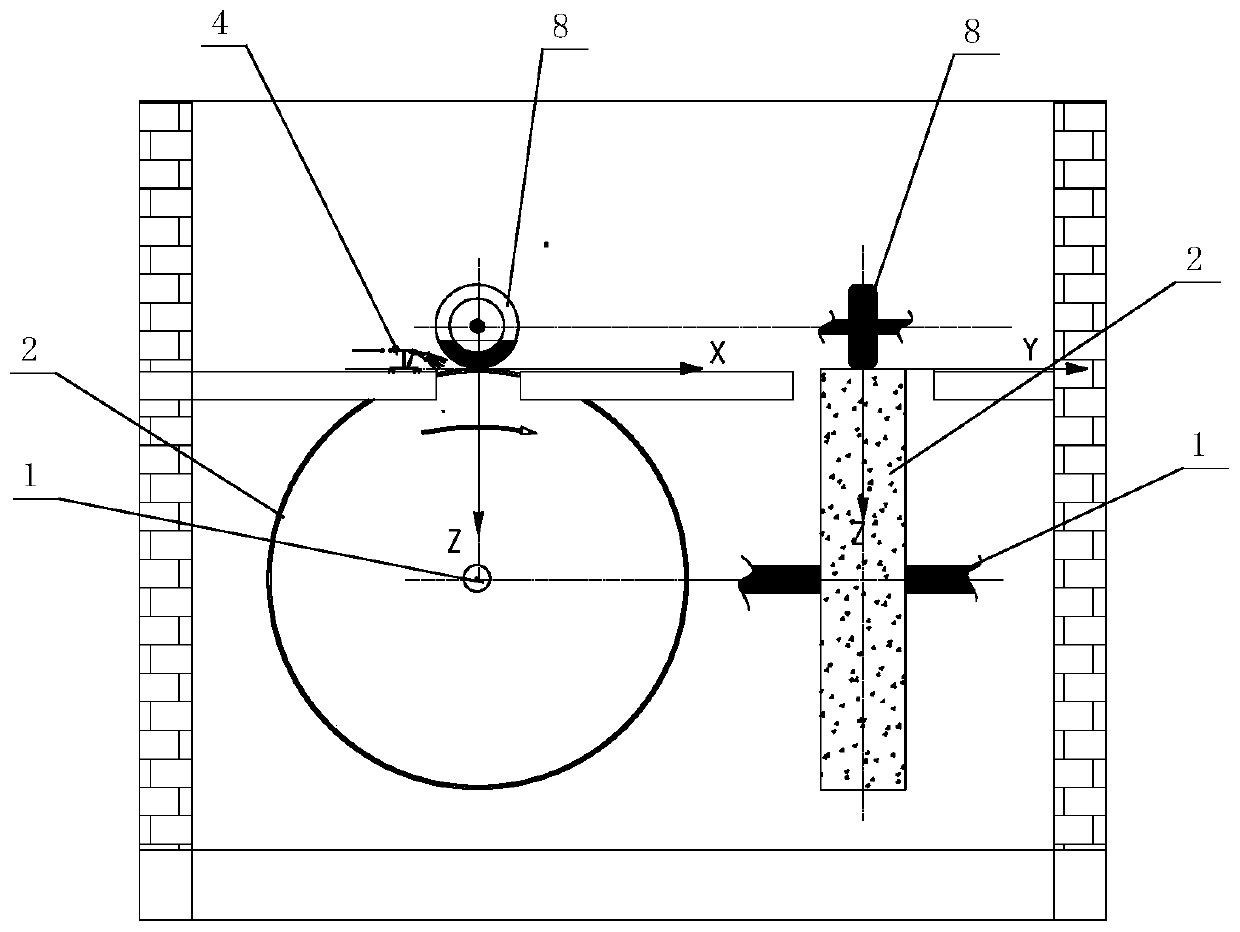

[0027] Example 1, such as figure 1 with figure 2 As shown, the experimental device applied to the tire wet skid performance test is divided into upper and lower layers, the upper layer is a tire chamber, and the lower layer is a drum chamber with a drum testing machine.

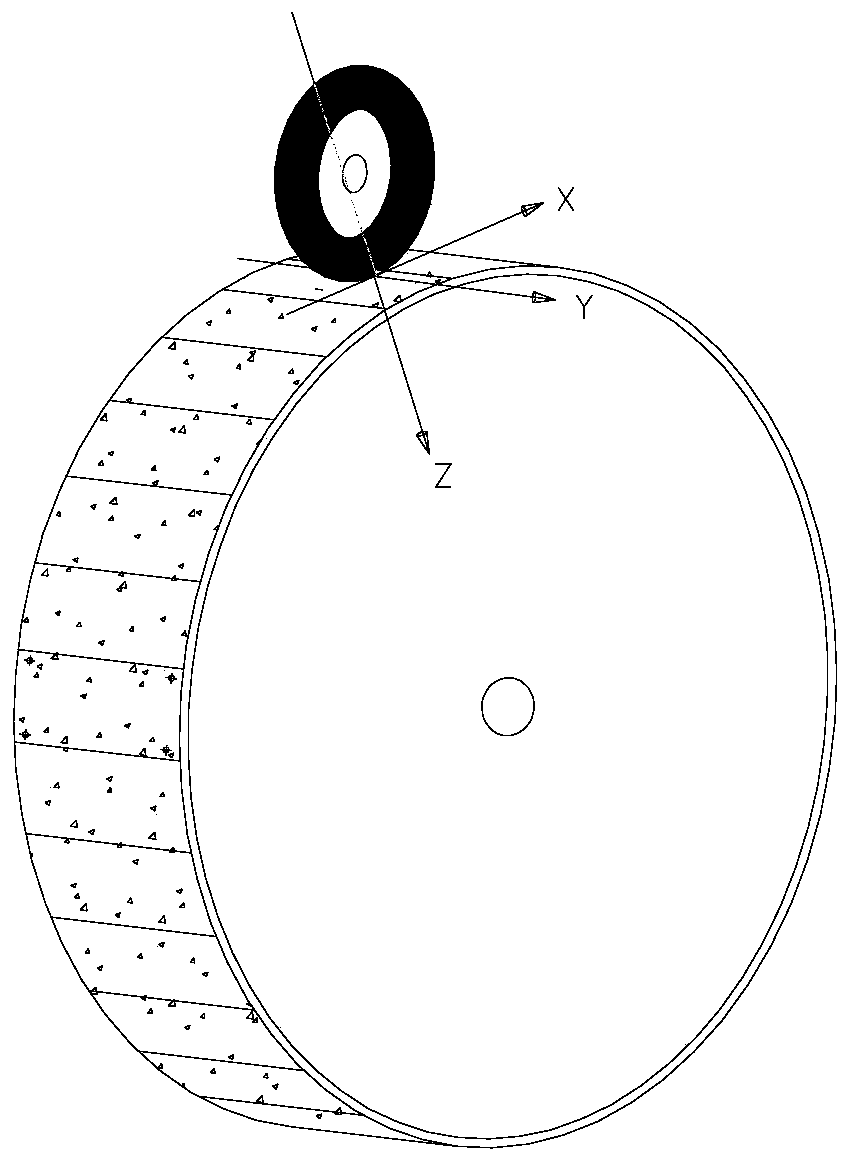

[0028] The drum testing machine includes a drum 2 axially mounted on a bearing 1 . During the experiment, the tire 8 and the drum 2 were in a vertical structure, and the central plane of the drum and the tire 8 coincided and were all perpendicular to the ground.

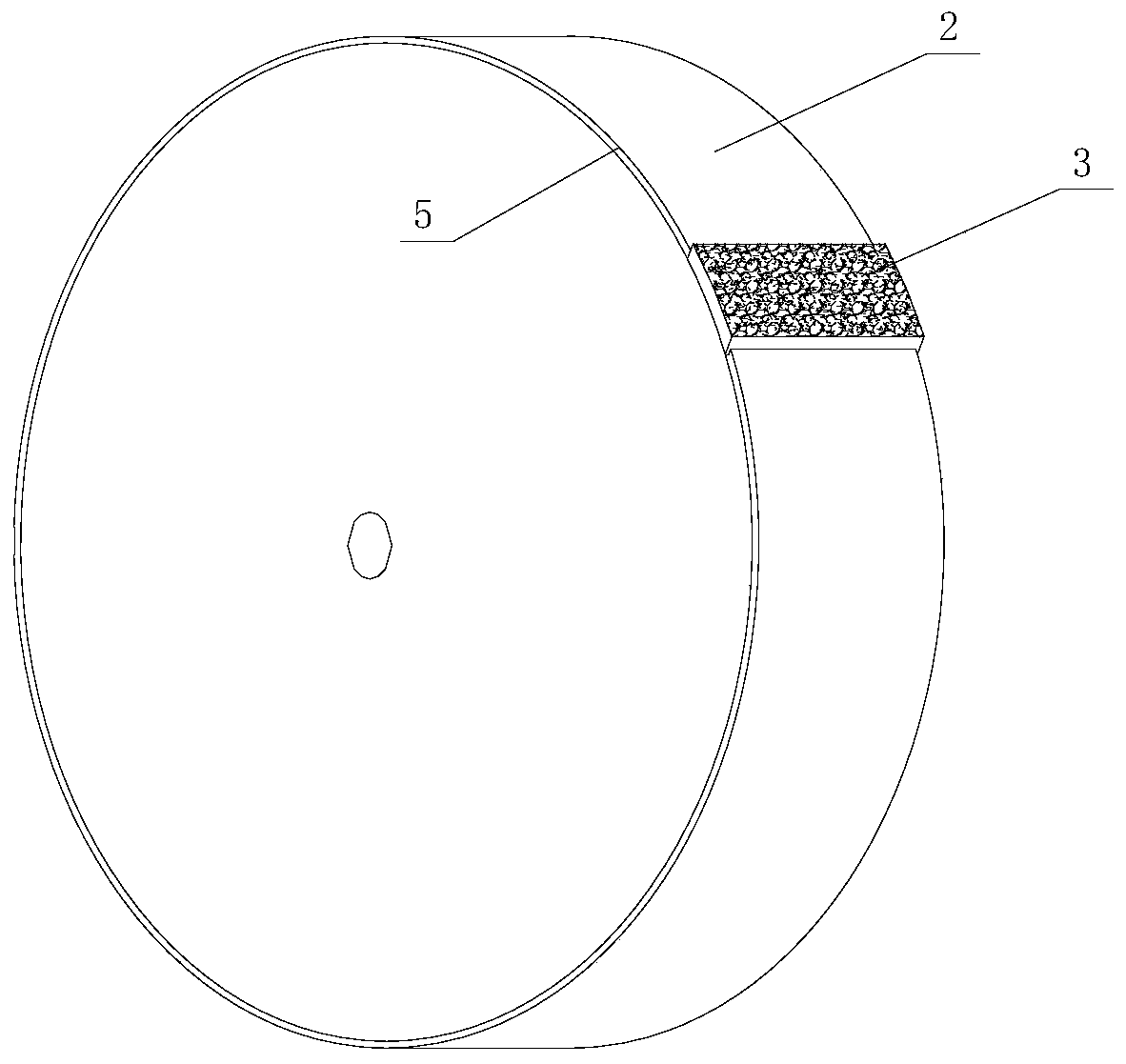

[0029] Drum 2 is a welded steel structure and needs to meet dynamic balance requirements and meet relevant ISO standards, with a diameter of 3m and an outer surface width of 650mm. Bearing 1 is a grease-lubricated roller bearing, and the outer surface of the drum is machined to ensure a smooth surface and precise dimensions.

[0030] On the circumferential outer surface of the drum 2 are inlaid 30 sector blocks 3 made of aluminum alloy and coate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com