Split-type tube bundle tank

A split-type, tube-bundle technology, which is applied in reactors, nuclear engineering, and portable protective containers, can solve problems such as storage or transfer of radioactive materials, small space for storing materials, and leakage of radioactive materials, etc., to avoid radioactive materials. The effect of preventing liquid leakage, increasing the available storage space, and improving the absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

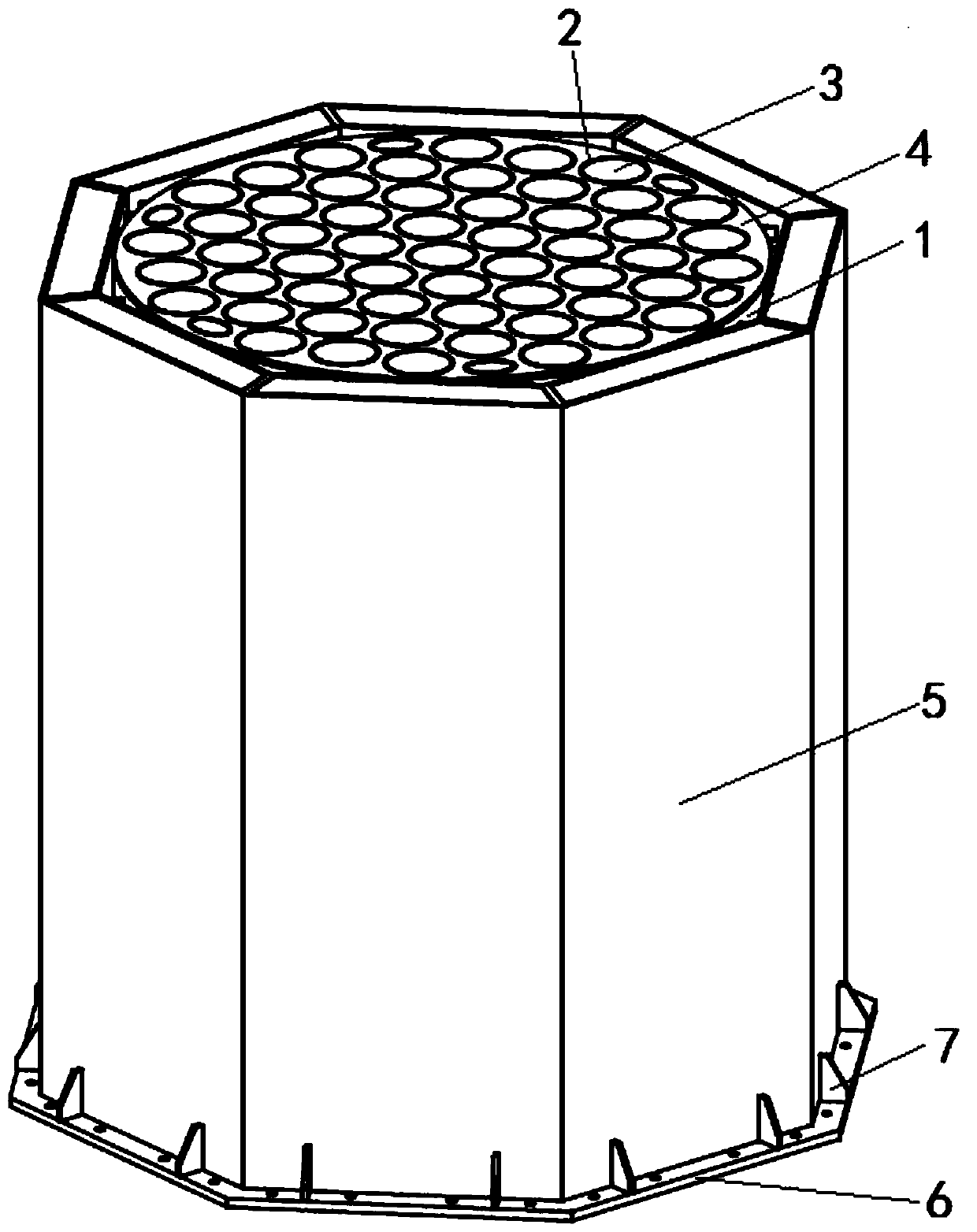

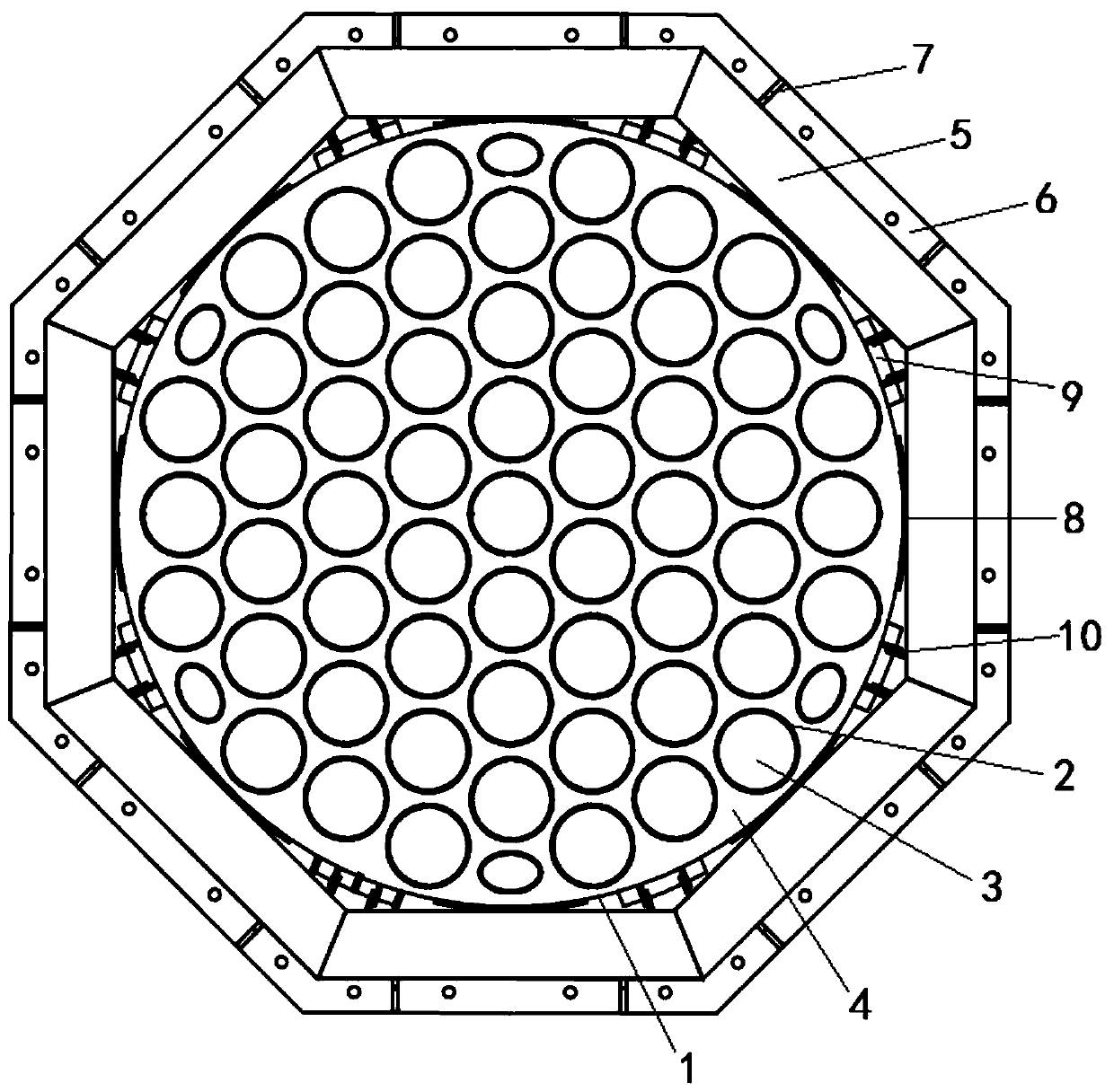

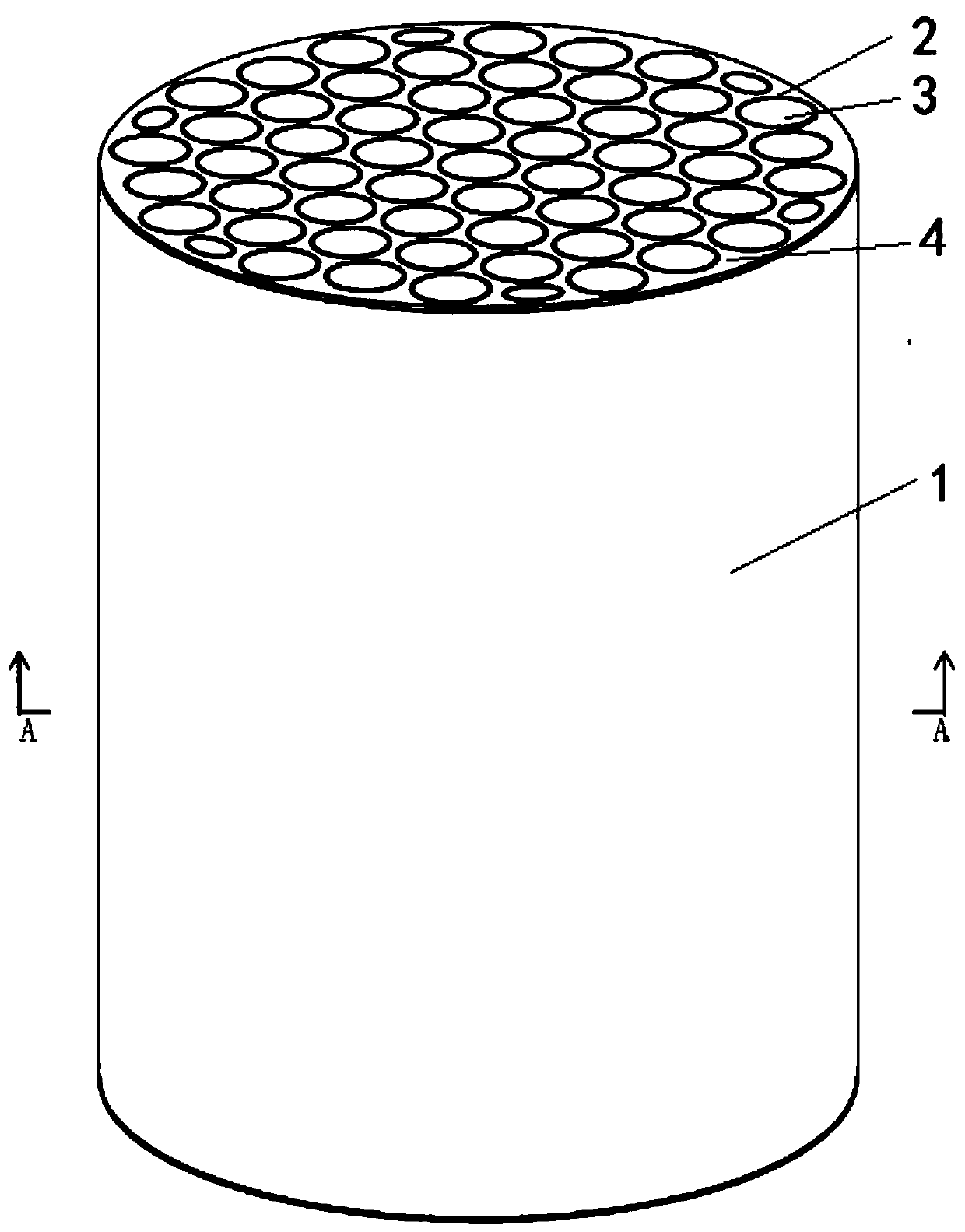

[0033] This embodiment discloses a split-type tube bundle trough, which adopts a split-type structure design, that is, includes an inner container and an outer frame, and the inner container and the outer frame are two mutually independent structures. The inner container is used to store reflections that are prone to critical reactions (critical reactions refer to the release of new neutrons during the nuclear fission process, too many neutrons will cause criticality, resulting in unstable operation of the nuclear reactor, and even the danger of explosion in severe cases) The outer frame is sleeved outside the inner container to support the inner container.

[0034] Specifically, the inner container includes a container body 1 , a tube bundle 2 and a top cover 4 . The container body 1 is preferably a cylindrical container, the top cover 4 is set on the container body 1, and the top cover 4 is provided with a through hole, the shape and size of the through hole match the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com