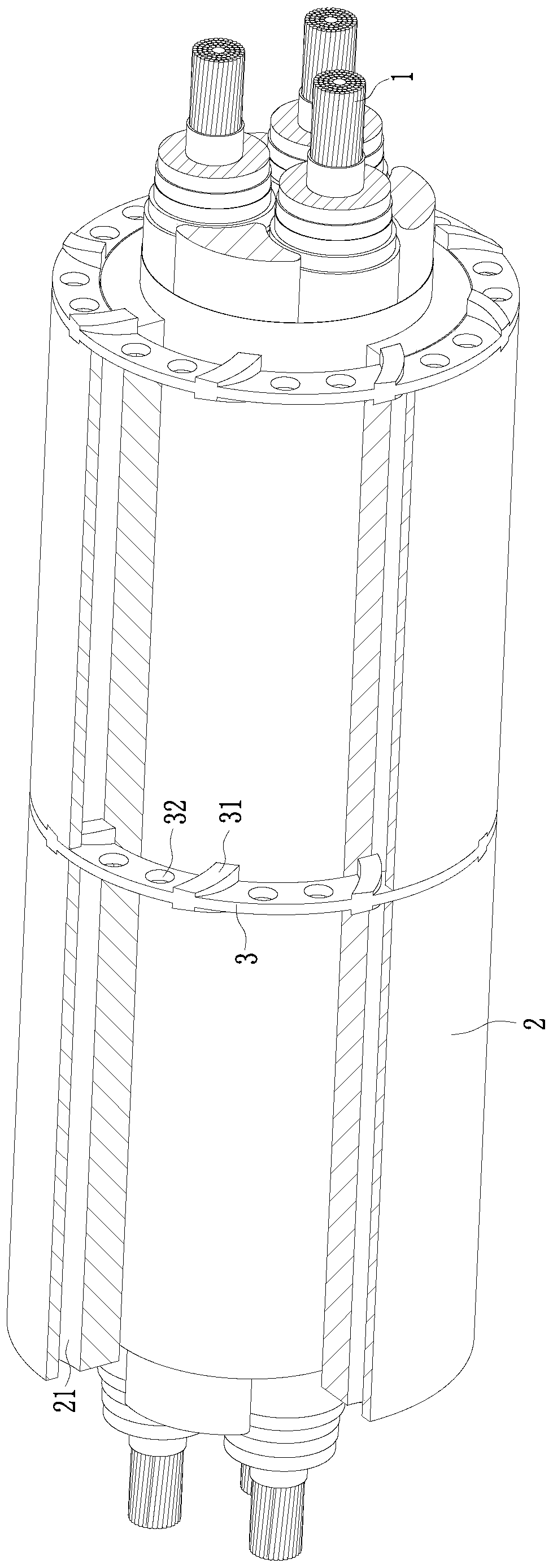

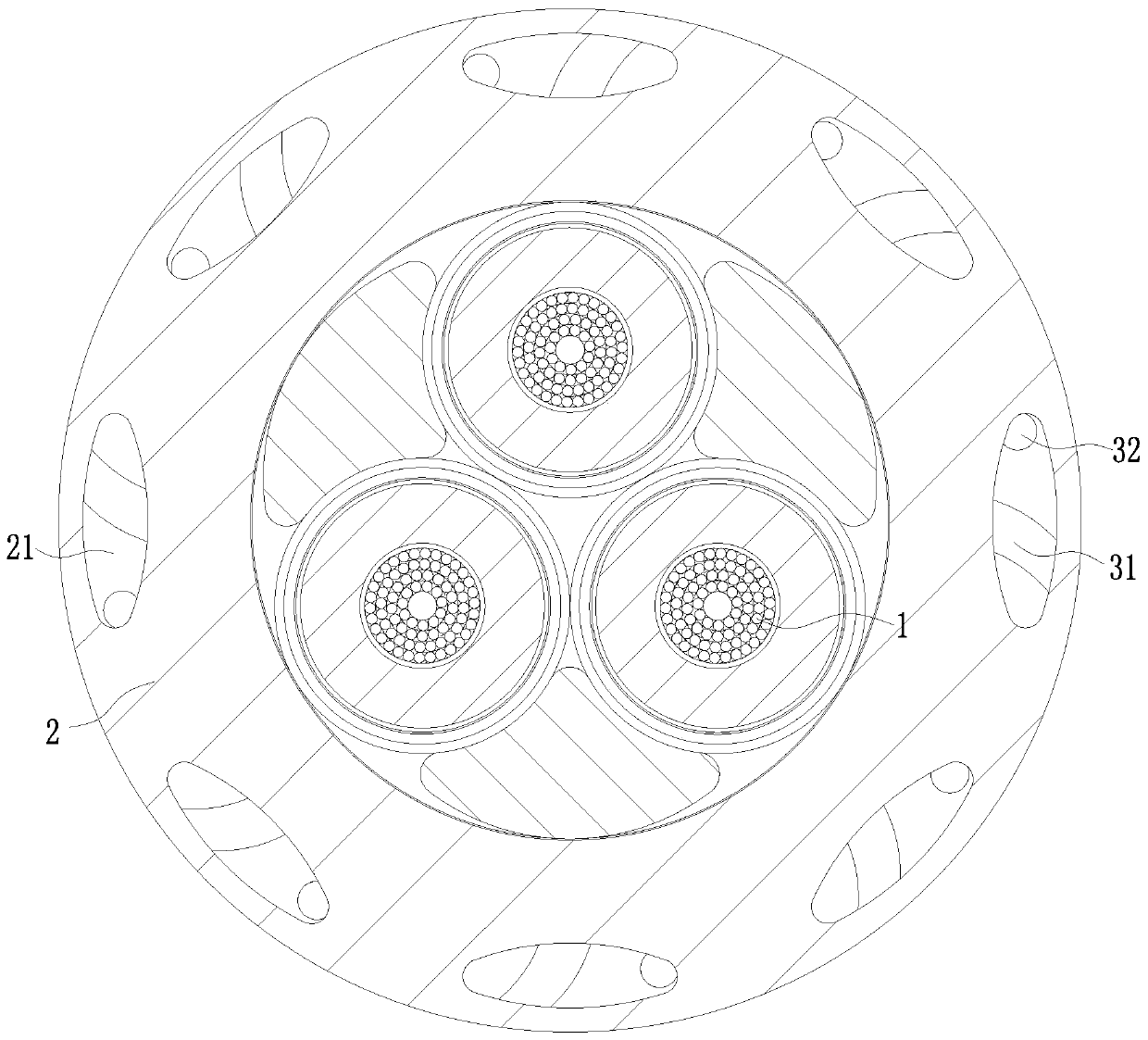

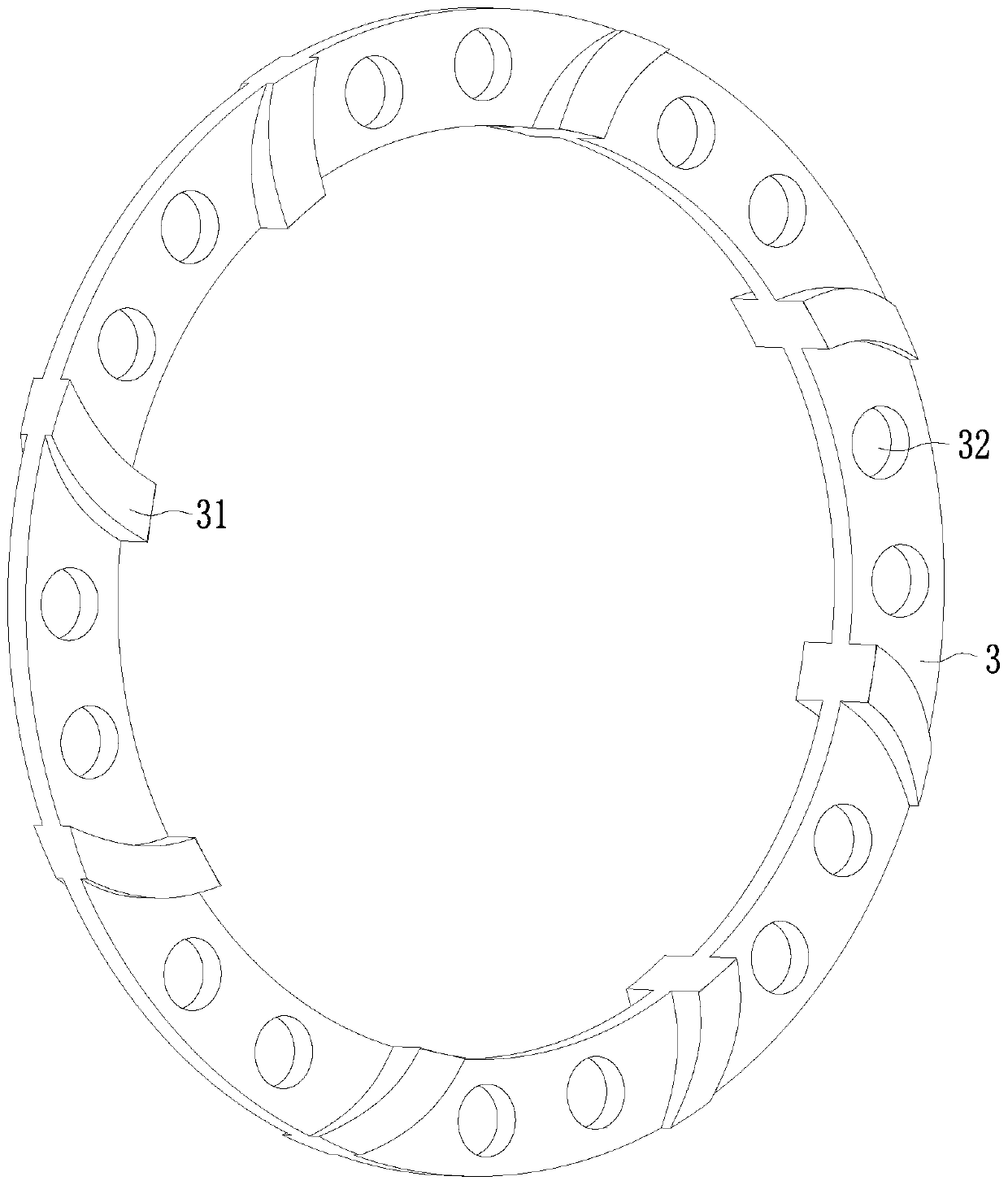

Environment-friendly wear resistant cable

An environmentally friendly and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve problems such as inability and inappropriateness, and achieve the effects of not being easily broken, increasing connection strength, and not being easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: a kind of bonding glue, comprises the raw material of following proportions by weight:

[0045] 30 parts of bisphenol A epoxy resin is one of the main components of the adhesive, and it is the matrix of the adhesive. After curing, the adhesive force is very strong, acid and alkali resistance, high mechanical strength, good electrical insulation, and Corrosion; 5 parts of phenolic epoxy resin, improve the crosslinking degree of the adhesive polymer, and improve the mechanical properties of the adhesive after curing; 10-15 parts of lubricant, mainly improve the lubricity of the adhesive, fire prevention, and corrosion resistance; 3 parts of hydrophobic fumed silica, mainly to provide sag resistance for the adhesive and prevent delamination of the adhesive; 12 parts of dicyandiamide curing agent, mainly to improve the curing speed of the adhesive; 12 parts of dehydrated and deoxidized glass fiber 1 part, mainly used as a reinforcing material to improve the te...

Embodiment 2

[0046] Embodiment 2: a kind of bonding glue, comprises the raw material of following proportions by weight:

[0047] 55 parts of bisphenol A epoxy resin is one of the main components of the adhesive, and it is the matrix of the adhesive. After curing, the adhesive force is very strong, acid and alkali resistance, high mechanical strength, good electrical insulation, and Corrosion; 3.5 parts of phenolic epoxy resin, improve the cross-linking degree of the adhesive polymer, and improve the mechanical properties of the adhesive after curing; 15 parts of lubricant, mainly improve the lubricity of the adhesive, fire prevention, and corrosion resistance; hydrophobicity 4 parts of fumed silica, mainly to provide sag resistance for the adhesive and prevent delamination of the adhesive; 7 parts of dicyandiamide curing agent, mainly to increase the curing speed of the adhesive; 10 parts of dehydrated deoxidized glass fiber, It is mainly used as a reinforcing material to improve the tens...

Embodiment 3

[0048] Embodiment 3: a kind of bonding glue, comprises the raw material of following proportions by weight:

[0049] 47 parts of bisphenol A type epoxy resin is one of the main components of the adhesive, and it is the matrix of the adhesive. After curing, the adhesive force is very strong, acid and alkali resistance, high mechanical strength, good electrical insulation, resistance Corrosion; 3 parts of phenolic epoxy resin, improve the crosslinking degree of the adhesive polymer, and improve the mechanical properties of the adhesive after curing; 10 parts of lubricant, mainly improve the lubricity, fire prevention and corrosion resistance of the adhesive; hydrophobicity 1 part of fumed silica, mainly to provide sag resistance for the adhesive and prevent delamination of the adhesive; 10 parts of dicyandiamide curing agent, mainly to increase the curing speed of the adhesive; 10 parts of dehydrated deoxidized glass fiber, It is mainly used as a reinforcing material to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com