Strong microcavity silicon-based organic light-emitting display device and forming method thereof

A technology of light-emitting display and organic light-emitting layer, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of weak micro-cavity effect, large electrode height drop, and difficult control of depth accuracy, so as to reduce uneven optical scattering , precise thickness control, and improved display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

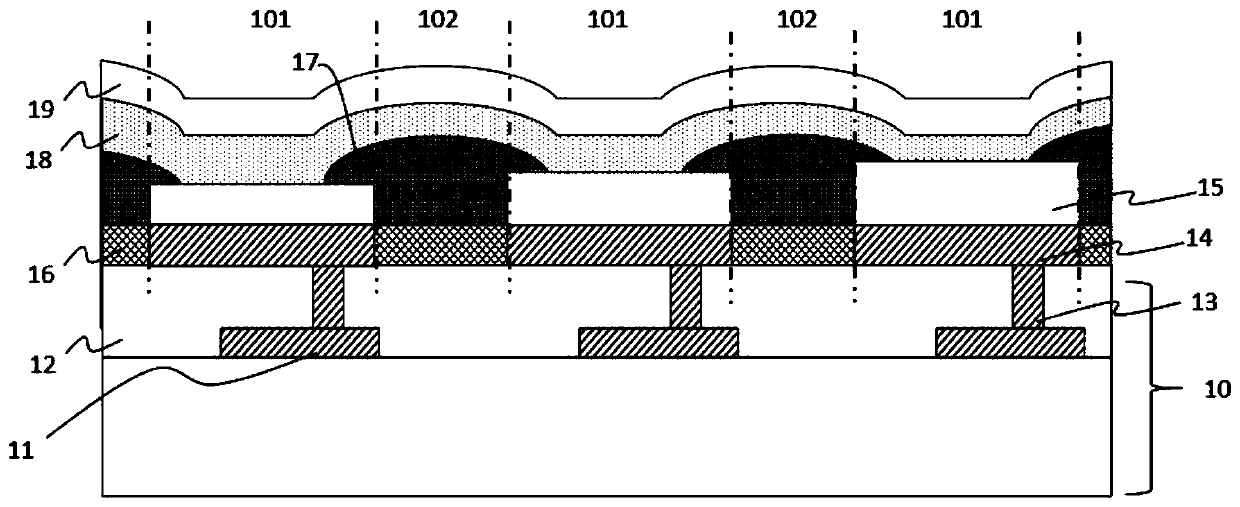

[0038] Please refer to figure 2 , figure 2 A schematic diagram of a strong microcavity silicon-based organic light-emitting display device provided for Embodiment 1 of the present invention, as shown in the figure, includes: a single crystal silicon substrate 10, on which the single crystal silicon substrate 10 includes a driving circuit layer, and the driving circuit layer includes pixels The driving structure 11 such as the driving circuit, the gate driving circuit, and the source driving circuit is provided with an insulating layer 12 on the upper layer of the driving structure 11 . A through hole 13 is provided in the insulating layer 12 to transmit the signal of the pixel driving circuit to the reflective electrode 14 .

[0039] The single crystal silicon substrate 10 includes pixel regions 101 and spacer regions 102 disposed between the pixel regions 101 , the reflective electrodes 14 are disposed in the pixel regions 101 , and the reflective electrodes 14 of each pix...

Embodiment 2

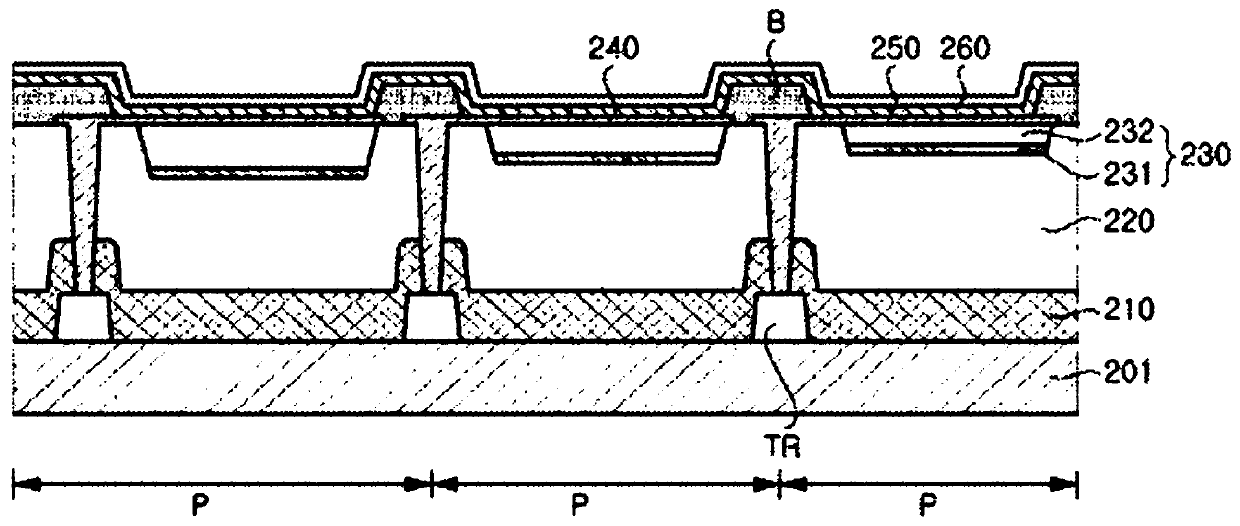

[0060] Please refer to Figure 7 , Figure 7 A schematic diagram of a strong microcavity silicon-based organic light-emitting display device provided for Embodiment 2 of the present invention, as shown in the figure, includes: a single crystal silicon substrate 20, and the single crystal silicon substrate 20 includes a driving circuit layer, and the driving circuit layer includes pixels The driving structure 21 such as the driving circuit, the gate driving circuit, and the source driving circuit is provided with an insulating layer 22 on the upper layer of the driving structure 21 . A through hole 23 is provided in the insulating layer 22 to transmit the signal of the pixel driving circuit to the reflective electrode 24 .

[0061] The single crystal silicon substrate 20 includes pixel regions 201 and spacer regions 202 arranged between the pixel regions 201, the reflective electrodes 24 are arranged in the pixel regions 201, and the reflective electrodes 24 of the pixel regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com