A kind of processing method of precious lead

A processing method and technology for precious lead, applied in the field of metallurgy, can solve the problems of high content, large carry-out, and high pressure on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

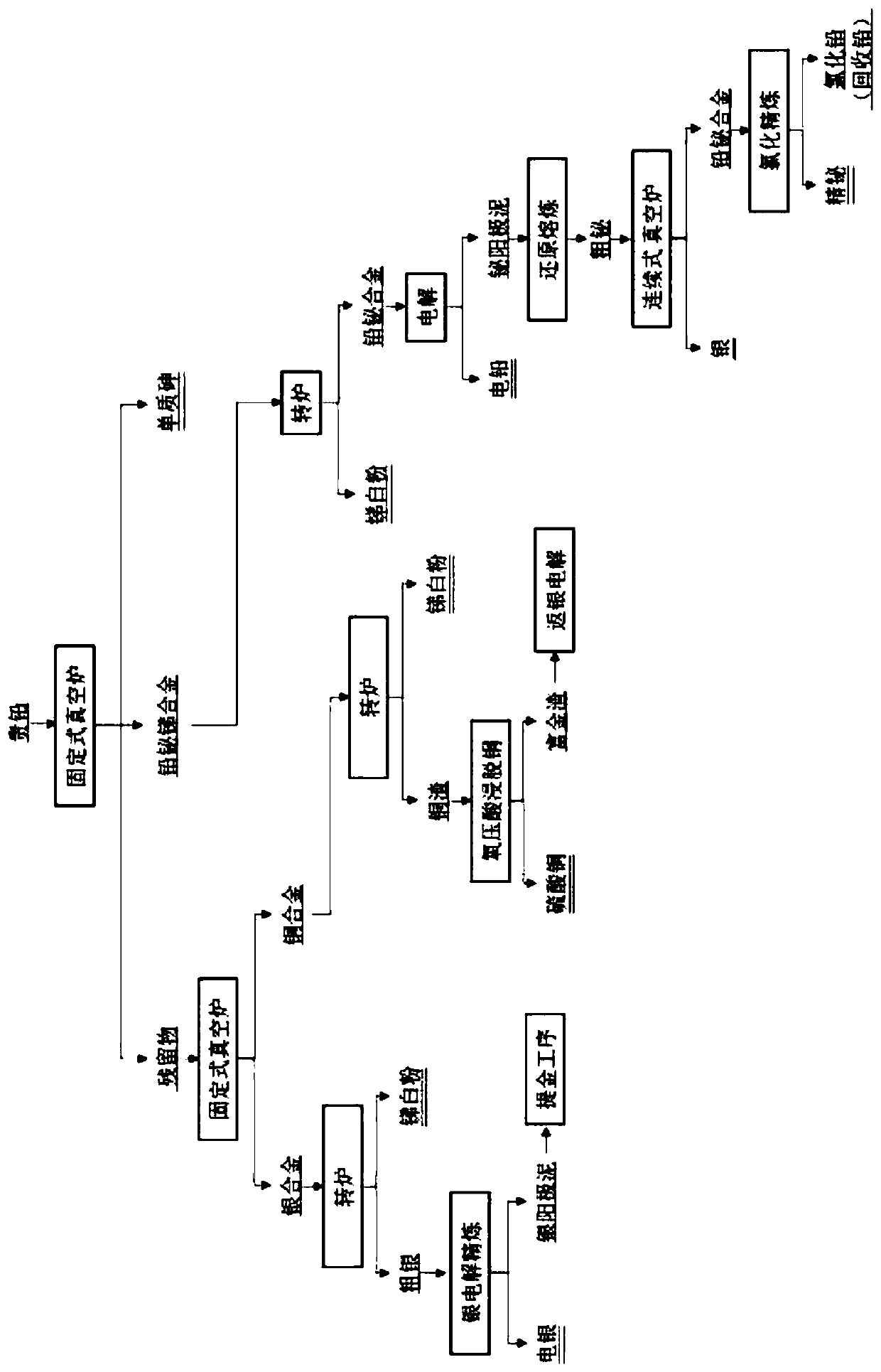

[0080] according to figure 1 The schematic diagram of the flow chart shows the comprehensive treatment of precious lead:

[0081] (1) 1000kg of precious lead material (Ag 11.8%, Cu 9.81%, Sb17.18%, As 16.14%, Pb 34.3%, Bi9.61%, Au 10.7g / t) is placed in a stationary vacuum distillation furnace, At a temperature of 850°C and a vacuum of 10Pa, vacuum distillation was carried out for 6 hours, and elemental arsenic (Ag 0.03%, Cu 0.02%, As97%, Pb+Bi+Sb 2%) 155kg, the primary condensing pan (500-300°C) to obtain 520kg of lead-bismuth-antimony alloy (Ag 2000g / t, Cu0.04%, Sb 3%, Pb+Bi95%, As 1%), and the bottom of the crucible to obtain residual Material (As 0.8%, Ag 36%, Cu30%, Sb31%, Pb+Bi 0.1%) 320kg;

[0082] (2) The lead-bismuth-antimony alloy that described step (1) obtains is carried out converter oxidation refining, obtains antimony white powder 18.7kg and lead-bismuth alloy (Pb 76%, Bi 23.2%) 494kg; Wherein the warm temperature of converter oxidation refining is 950 ℃, the ...

Embodiment 2

[0095] according to figure 1 The schematic diagram of the flow chart shows the comprehensive treatment of precious lead:

[0096] (1) 1000kg of precious lead material (Ag 11.8%, Cu 9.81%, Sb17.18%, As 16.14%, Pb 34.3%, Bi9.61%, Au 10.7g / t) is placed in a stationary vacuum distillation furnace, At a temperature of 950°C and a vacuum of 20Pa, vacuum distillation was carried out for 5 hours, and elemental arsenic (Ag 0.02%, Cu 0.03%, As97.6%, Pb+Bi +Sb1.8%) 154.6kg, the primary condensation pan (500~300℃) to obtain lead-bismuth-antimony alloy (Ag 2000g / t, Cu 0.03%, Sb 2.7%, Pb+Bi 95.8%, As 0.76%) 518.9kg , the bottom of the crucible obtained residue (As 0.78%, Ag 36.2%, Cu 30.1%, Sb 30.6%, Pb+Bi 0.1%) 318.9kg;

[0097] (2) The lead-bismuth-antimony alloy that described step (1) obtains is carried out converter oxidation refining, obtains antimony white powder 18.8kg and lead-bismuth alloy (Pb 75.8%, Bi 24%) 493kg; Wherein the warm temperature of converter oxidation refining is ...

Embodiment 3

[0110] according to figure 1 The schematic diagram of the flow chart shows the comprehensive treatment of precious lead:

[0111] (1) 1000kg of precious lead material (Ag 11.8%, Cu 9.81%, Sb17.18%, As 16.14%, Pb 34.3%, Bi9.61%, Au 10.7g / t) is placed in a stationary vacuum distillation furnace, At a temperature of 1000°C and a vacuum of 30Pa, vacuum distillation was carried out for 6 hours, and elemental arsenic (Ag 0.021%, Cu0.02%, As 96%, Pb+Bi +Sb 2.2%) 154.5kg, a lead-bismuth-antimony alloy (Ag2200g / t, Cu 0.03%, Sb 3.2%, Pb+Bi 95.1%, As 1%) 521kg, crucible bottom The residue (As0.78%, Ag 36.5%, Cu 29.8%, Sb 30.7%, Pb+Bi 0.1%) 320.2kg was obtained;

[0112] (2) the lead-bismuth-antimony alloy that described step (1) obtains is carried out converter oxidation refining, obtains antimony white powder 17.9kg and lead-bismuth alloy (Pb 76.1%, Bi 22.9%) 494.5kg; Wherein the temperature temperature of converter oxidation refining is 1000°C for 15 minutes, top-blown oxygen provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com