Cable penetrating method and system for low tower cable-stayed bridge

A low-tower cable-stayed bridge and cable threading technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of a large number of threading cables and the inability to use cable threading technology, etc., so as to reduce the difficulty of manual operation, reduce construction risks, Ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

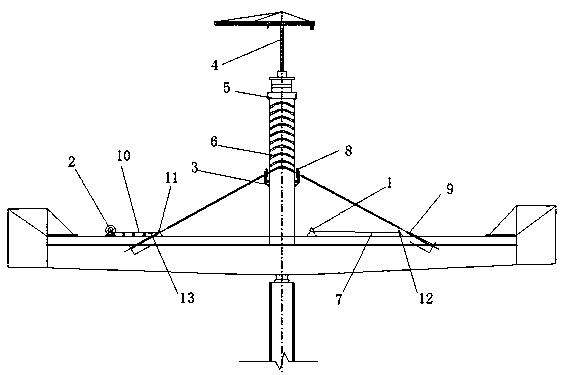

[0044] Refer to attached figure 1 Shown, a kind of low-tower cable-stayed bridge threading method comprises the following steps:

[0045] Step 1: Number the cable saddle 6 of the split pipe and the pre-embedded cable tube 9 of the main beam correspondingly;

[0046] Step 2: Pass the traction rope 7 through the wire splitting pipe saddle 6, connect one end to the winch 1, and connect the other end to the steel strand 10;

[0047] Step 3: start the hoist 1 to rewind the traction rope 7, pass one end of the steel strand 10 through the wire splitting pipe saddle 6, and then install the two ends of the steel strand 10 into the embedded cable tubes 9 on both sides of the main beam;

[0048] Step 4: Repeat steps 1-3 until all steel strands 10 are threaded.

[0049] As a further optimization of the scheme, step 1 includes the following steps:

[0050] Step 1.1: Number the N splitting tube saddles 6 in the main tower 5, numbered 1-N, and mark the number on each splitting tube saddle 6...

Embodiment 2

[0069] Please refer to figure 1 , The difference between this embodiment and Embodiment 1 is that this embodiment provides a rope system applying the method of the embodiment.

[0070] A cable threading system for a cable-stayed bridge with low towers, comprising a hoist 1, a cable reel 2, a cable threading work platform 3 and a hanging tower 4, the hanging tower 4 is arranged on the top of the main tower 5, and the cable threading working platform 3 is arranged on the main tower On the 5th surrounding wall, the winch 1 and the cable reel 2 are respectively placed on the bridge decks on both sides of the main tower 5; it also includes a traction rope 7, an operator 8, and the suspension tower 4 hoists the traction rope 7 to the rope-threading work platform 3, The operator 8 connects one end of the traction rope 7 through the saddle 6 of the wire splitting pipe to the hoist 1, and the other end to the steel strand 10 on the cable reel 2; The steel strand 10 drives and passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com