Calibration and calibration method and system of gas sensor

A technology of gas sensor and calibration method, which is applied in standard gas analyzers, closed-circuit television systems, and analysis of gas mixtures, etc. It can solve problems such as time-consuming, cumbersome process, and impact on gas sensor accuracy, so as to reduce delivery time and improve safety. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

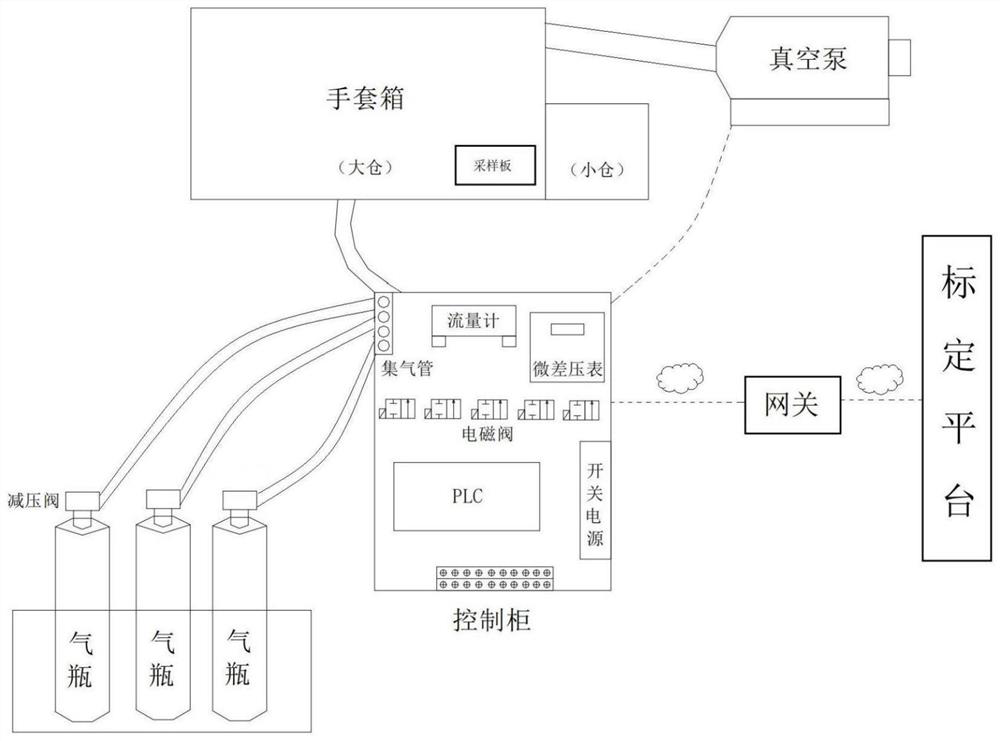

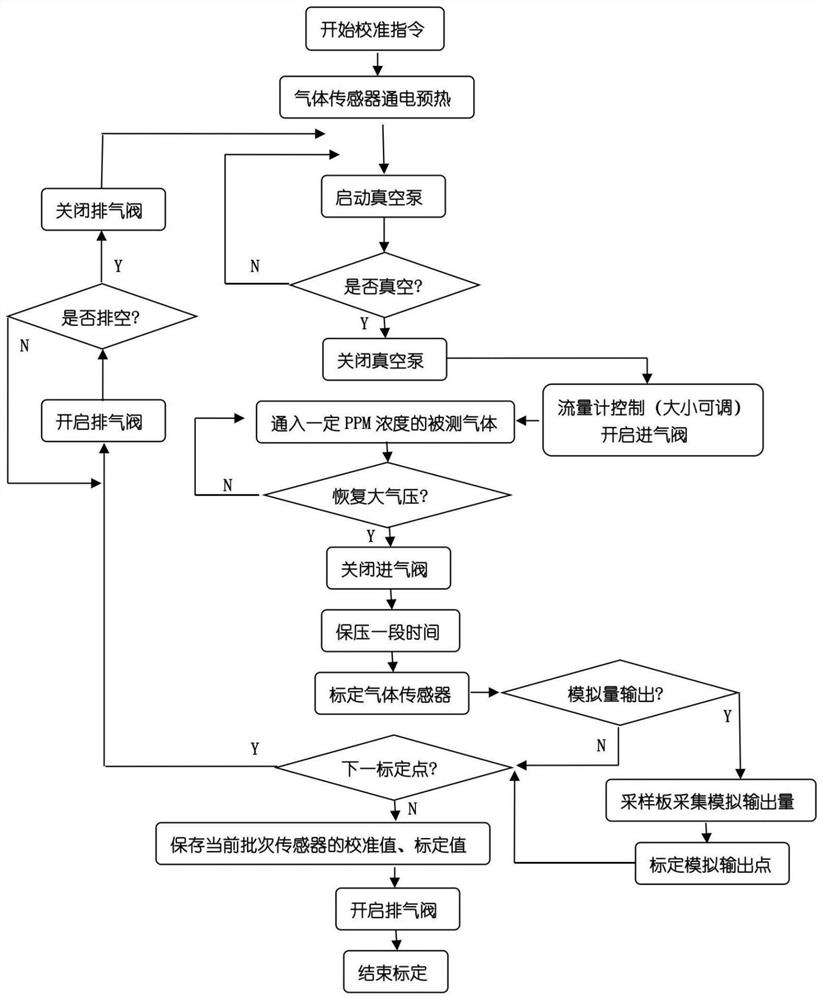

[0034] Such as Figure 1-4 As shown, a calibration and calibration method for a gas sensor comprises the following steps:

[0035] S101. Measure the output of the gas sensor in two or more gas environments with known concentrations, the output is voltage or current, and voltage is selected in this embodiment;

[0036]Among them, the output of the gas sensor is measured, specifically: the operator puts the gas sensor into the gas calibration chamber (calibration device), operates the control cabinet, and uses the PLC to control the vacuum pump to evacuate the gas in the calibration device, so that the calibration device is a vacuum or Close to the vacuum state, then close the vacuum valve (such as vacuum solenoid valve), open the intake solenoid valve, depressurize the gas with known concentration and pass it into the calibration device through the flow meter (collecting flow data); the process of passing the gas In the process, the proportional valve is used to adjust the int...

Embodiment 2

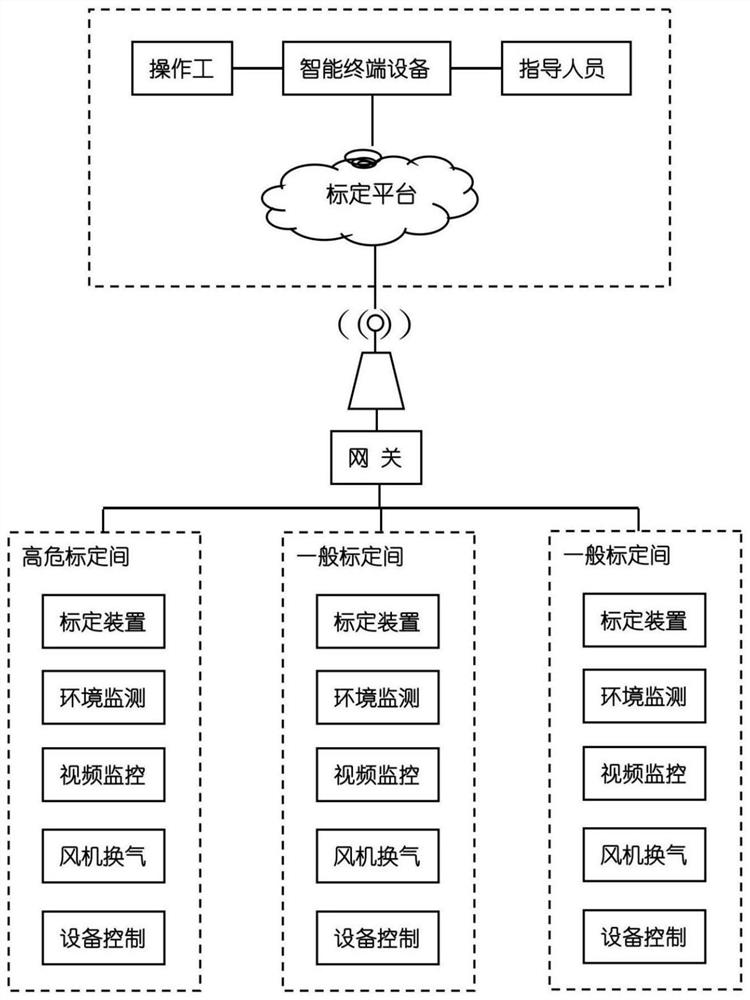

[0055] A method for calibrating and calibrating a gas sensor based on a cloud platform, comprising the following steps:

[0056] S301. The gas sensor is placed in the calibration device in the calibration room, and the calibration platform sends a calibration command, which is transmitted to the control cabinet through the gateway;

[0057] S303. The control cabinet causes the PLC to control the vacuum pump to evacuate the gas in the calibration device to form a gas environment with a known concentration in the calibration device; wherein, a gas environment with a known concentration is formed in the calibration device, specifically: operate the control cabinet and use PLC control The vacuum pump evacuates the gas in the calibration device to make the calibration device in a vacuum or close to a vacuum state, then close the vacuum valve (such as a vacuum solenoid valve), open the intake solenoid valve, and decompress the gas with a known concentration (by reducing pressure ele...

Embodiment 3

[0081] A method for calibrating and calibrating a gas sensor based on a cloud platform, comprising the following steps:

[0082] S501. The gas sensor is placed in the calibration device in the calibration room, and the calibration platform sends a calibration command, which is transmitted to the control cabinet through the gateway;

[0083] S503, the control cabinet causes the PLC to control the vacuum pump to evacuate the gas in the calibration device, forming a gas environment of known concentration in the calibration device; wherein, forming a gas environment of known concentration in the calibration device, specifically: operating the control cabinet, using PLC control The vacuum pump evacuates the gas in the calibration device to make the calibration device in a vacuum or close to a vacuum state, then close the vacuum valve (such as a vacuum solenoid valve), open the intake solenoid valve, and decompress the gas with a known concentration (by reducing pressure electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com