Installation method of semi-submersible barge crawler crane offshore large wind power generator

A technology of a wind turbine and an installation method, which is applied to the assembly of wind turbines, wind energy power generation, ships, etc., can solve the problems of low transportation safety factor, high construction cost, affecting construction safety, etc., so as to reduce installation cost, improve installation and The effect of transportation efficiency and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

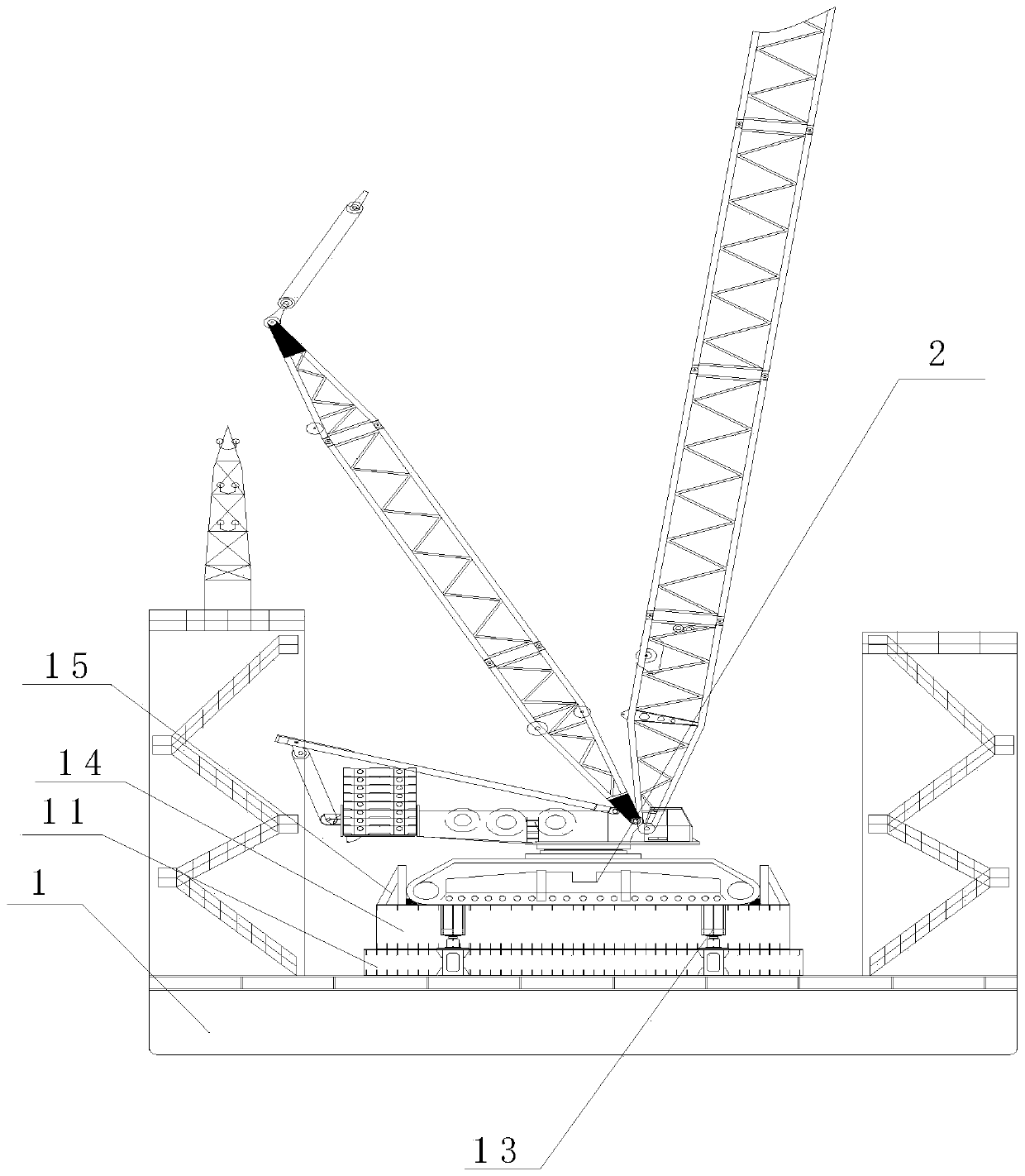

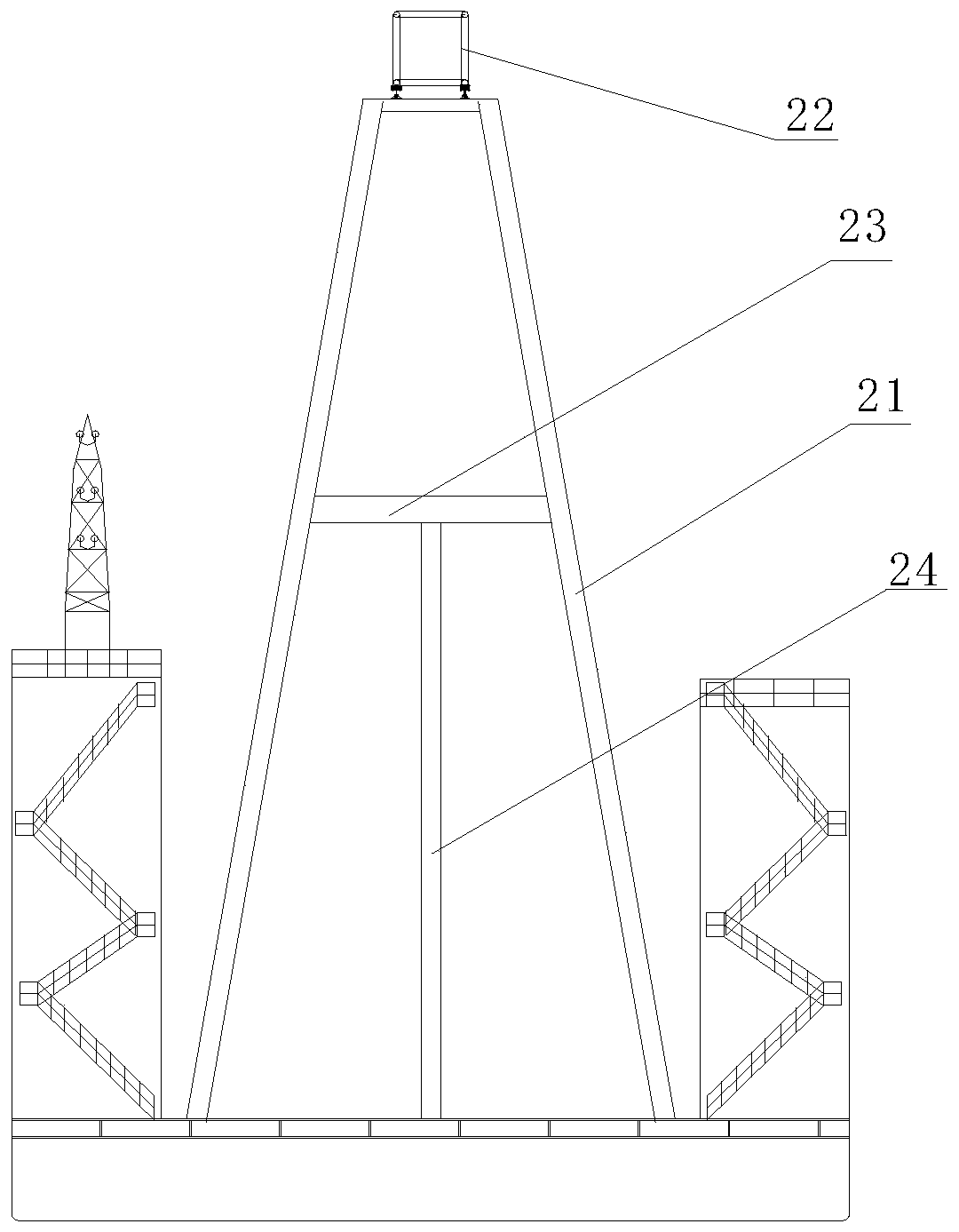

[0035] Such as Figure 1 to Figure 4 As shown, the semi-submerged barge crawler crane includes a semi-submersible barge 1 and a crawler crane 2. The middle part of the semi-submersible barge 1 is welded and fixedly connected with two symmetrically arranged lower box girders 11 made of steel plates with a thickness of 20 mm. Both sides of the lower box girder 11 are fixedly connected with two corbels 12, and each corbel 12 is fixedly equipped with a hydraulic jack 13 with a stroke of 25 cm. The output end of the hydraulic jack 13 supports the crawler belt of the crawler crane 2. Each lower box beam 11 is fixedly connected with an upper box beam 14 using bolts of M20mm.

[0036] Both ends of the two upper box girders 14 are fixedly connected with track baffles 15 to prevent the tracks from running off, and the two upper box girders 14 are welded and fixedly connected with three parallel sets and welded by 125×10mm equilateral angle steel. Formed truss 16.

[0037] The crawler ...

Embodiment 2

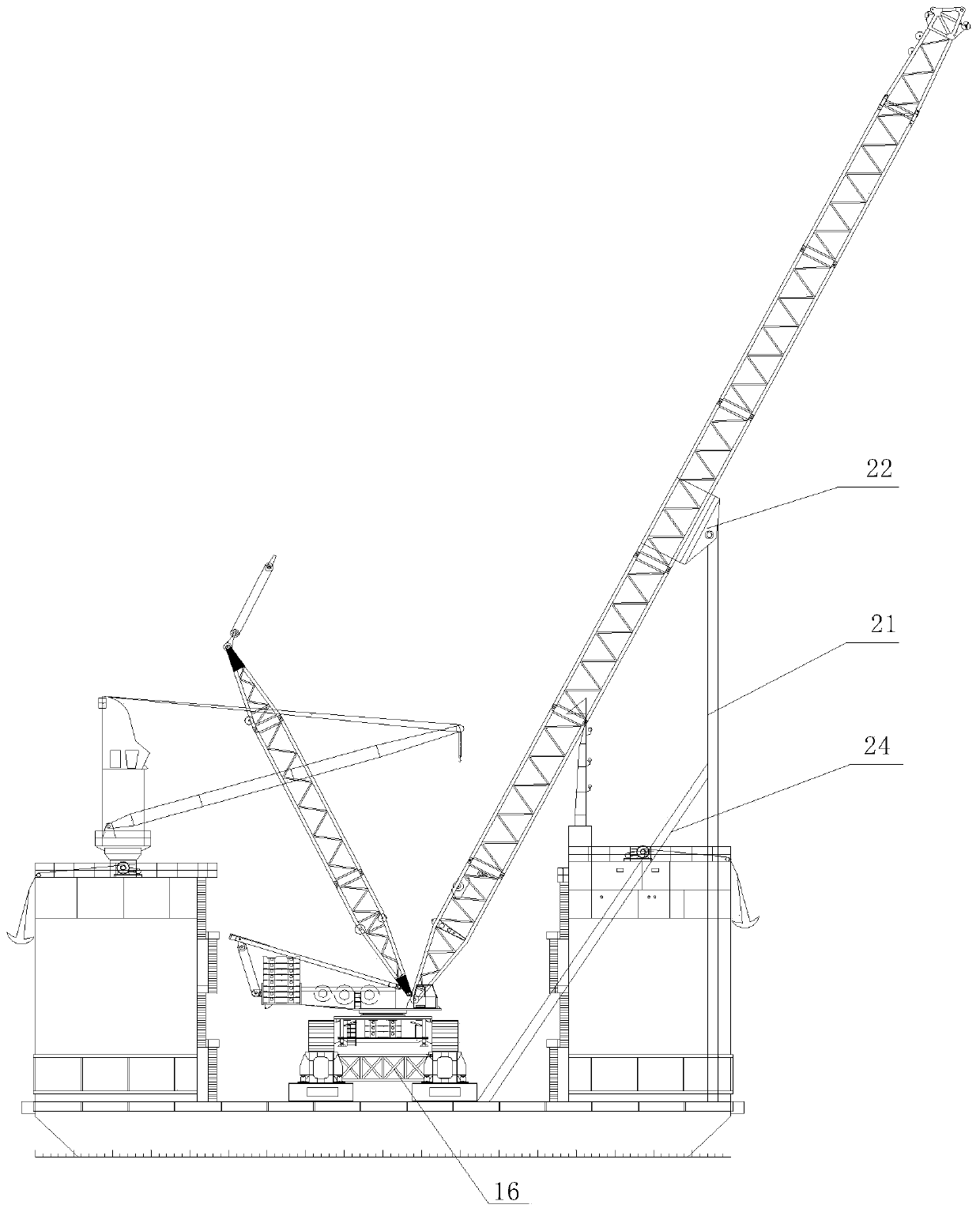

[0040] Such as Figure 5 to Figure 7As shown, using the semi-submerged barge crawler crane in Embodiment 1 for the installation of large offshore wind-driven generators is carried out according to the following construction steps:

[0041] Step 1. First transfer the refitted semi-submersible barge crawler crane tugboat to the wind turbine stand;

[0042] Step 2. Bottom of the semi-submersible barge crawler hanger: anchoring and fixing in four directions on the semi-submersible barge crawler hanger;

[0043] Step 3. Loosen the pole support device of crawler crane 2;

[0044] Step 4. Adjust the level of the crawler crane 2: Use eight hydraulic jacks 13 to fine-tune to make it level;

[0045] Step 5. Use the semi-submersible barge crawler crane as the main crane to cooperate with the small floating crane 3 for installation;

[0046] Step 6, the hook of the semi-submerged barge crawler crane is fixed on the upper end of the first section of the tower 42 with a wire rope, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com