Detection device for detonating signal of perforating magnetoelectric detonator

A detonation signal and detection device technology, applied in fuzes, weapon accessories, offensive equipment, etc., can solve the problems of unfavorable on-site operation, lack of oscilloscope, high cost, etc., and achieve the effect of avoiding engineering accidents and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

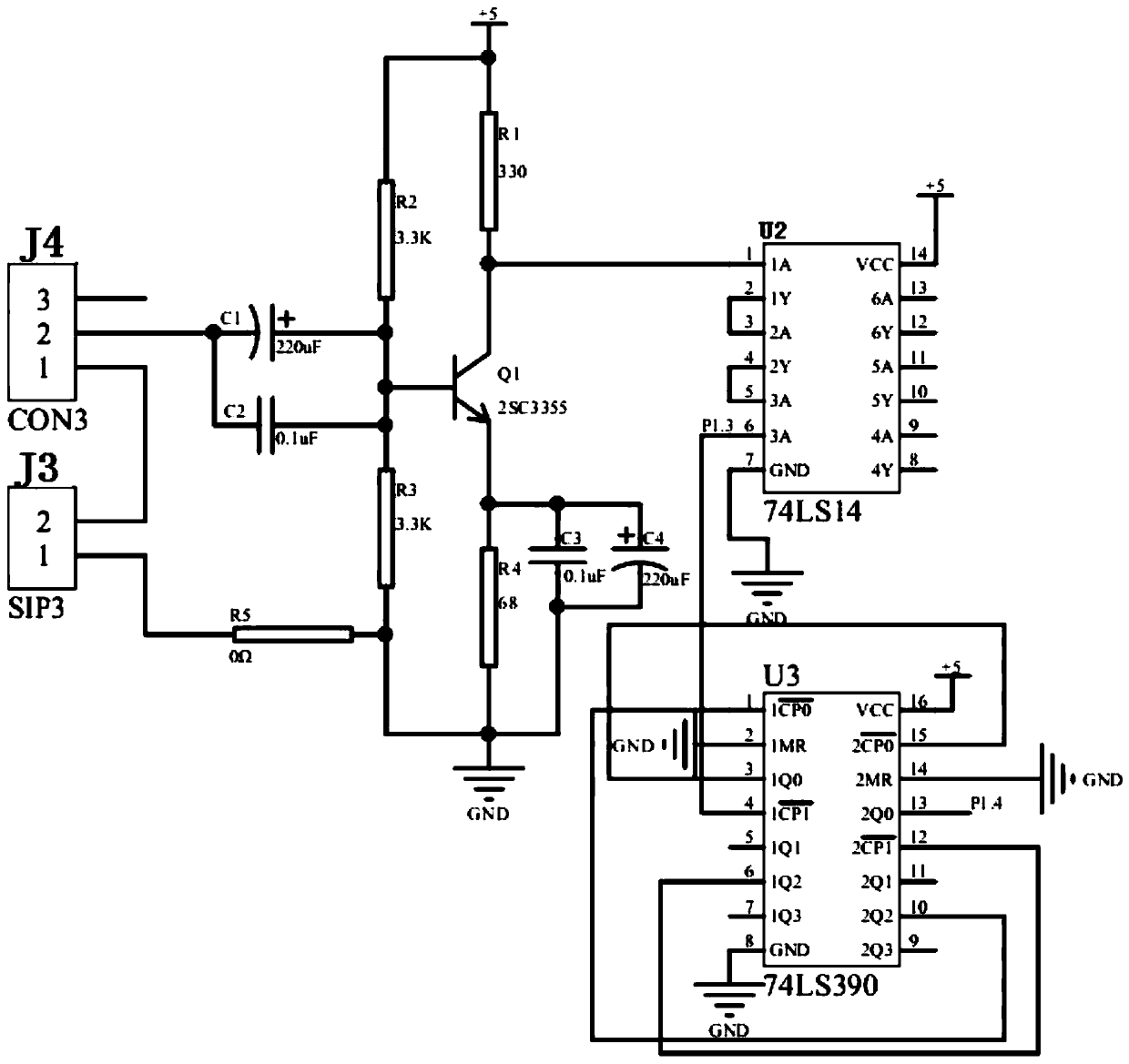

[0029] The frequency detector is mainly used to detect the detonation signal given by the magnetoelectric detonator detonator. The signal is a signal with a short pulse (about 0.1 second) and a high frequency (tens or even hundreds of KHz). If it cannot be used before construction Testing the signal cannot guarantee that the construction can be carried out normally and smoothly or even cause an engineering accident. Therefore, it is necessary to measure this detonation signal. The invention provides a perforation magnetoelectric detonator detonation signal detection device which can intuitively detect whether the detonation signal can be accurately transmitted to the detonator for the purpose of avoiding engineering accidents.

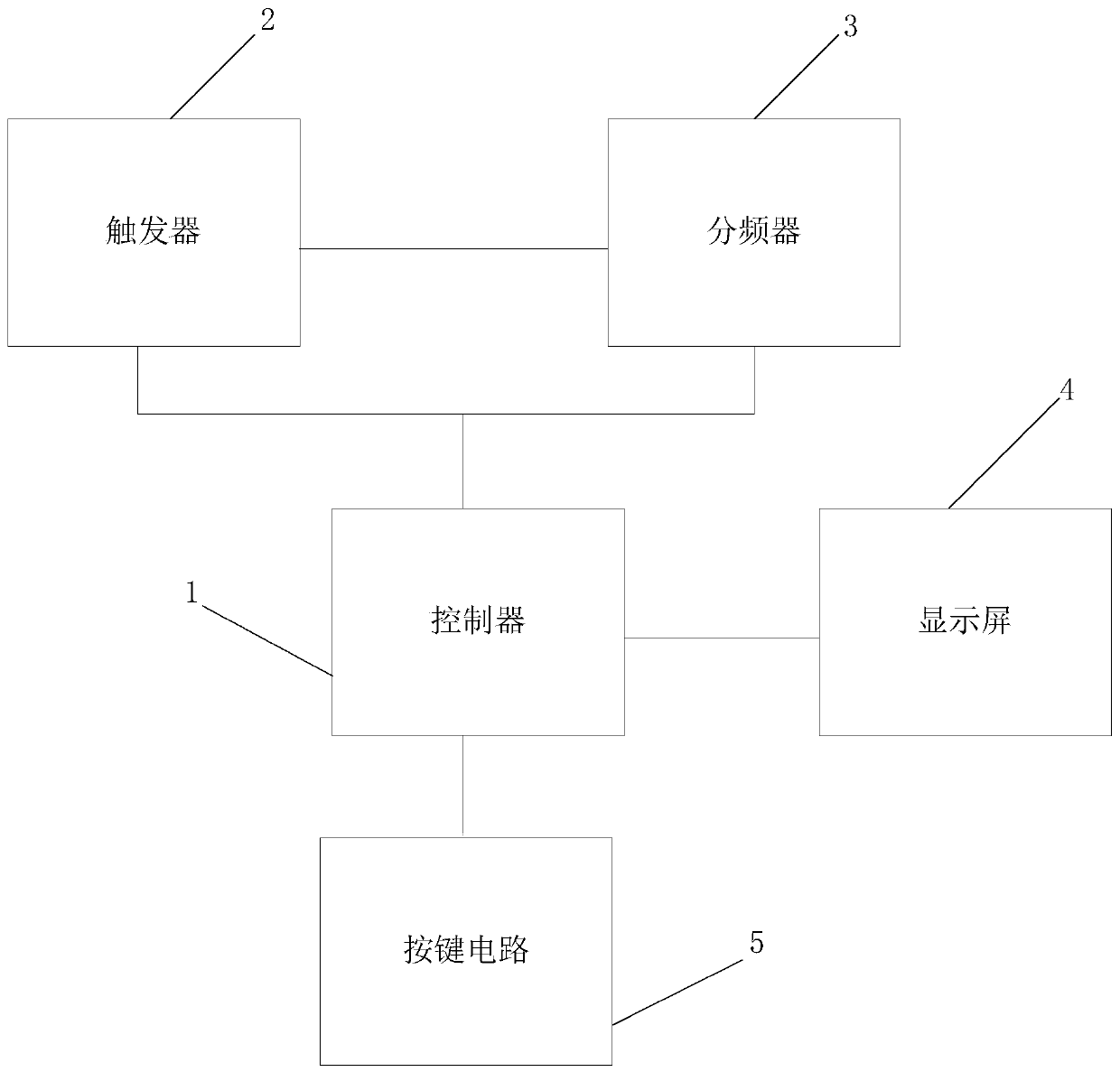

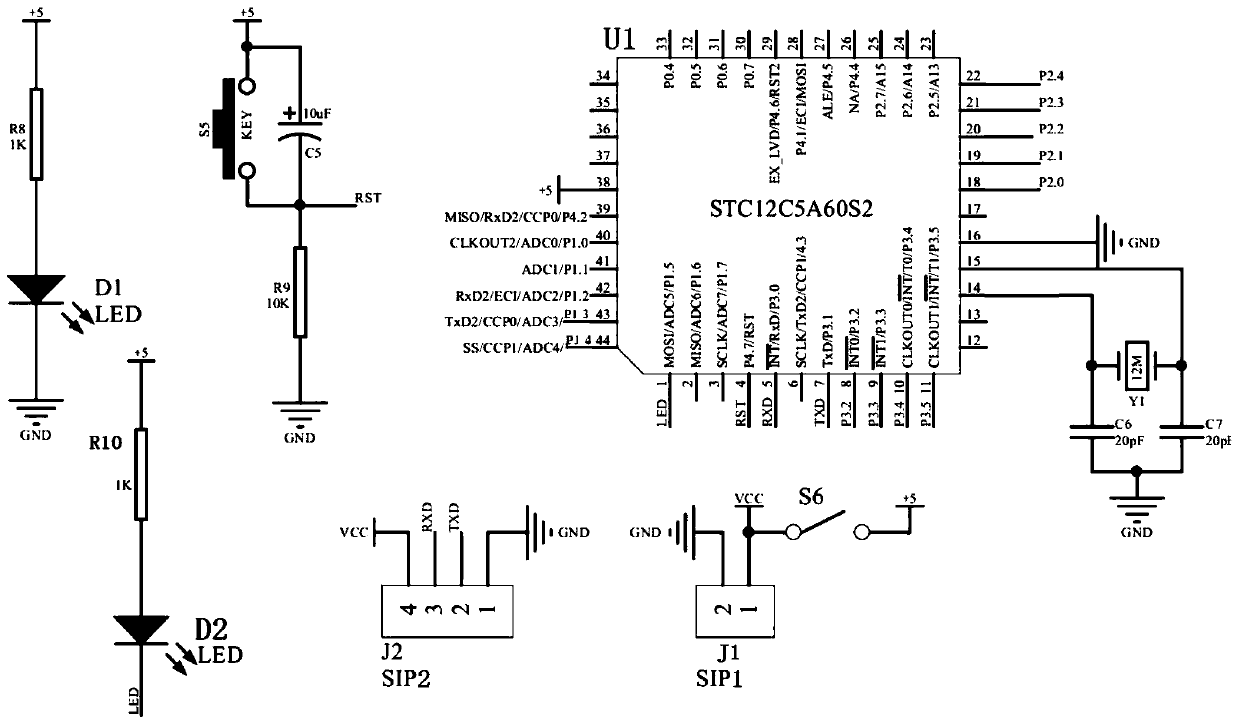

[0030] Such as figure 1 As shown, the present invention discloses a perforating magnetoelectric detonator detonation signal detection device, including a controller 1, and a trigger 2, a frequency divider 3, a display screen 4, and a button connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com