A non-destructive quantitative test method for three-dimensional mining stress field in working face

A technology of mining stress and testing methods, which is applied to measuring devices, seismology and instruments for logging records, etc., and can solve the problems of high dispersion and poor reliability of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features, and advantages of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0038] The present invention provides a method of non-destructive quantitative testing of three-way pilot stress fields in front of the coal rock body in front of the work, to solve the conventional drilling stress test method can only perform a qualitative test of local single direction stress, test results. Explulsses, high reliability, etc.

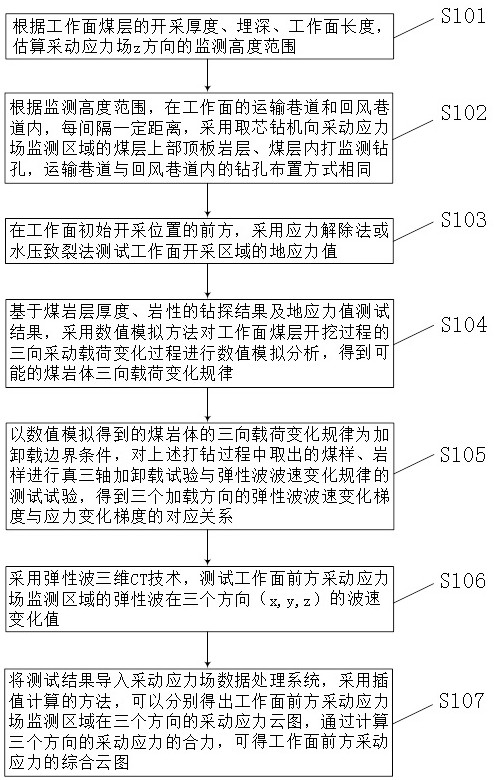

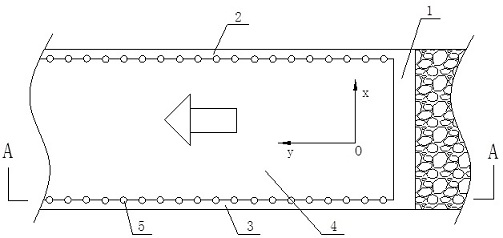

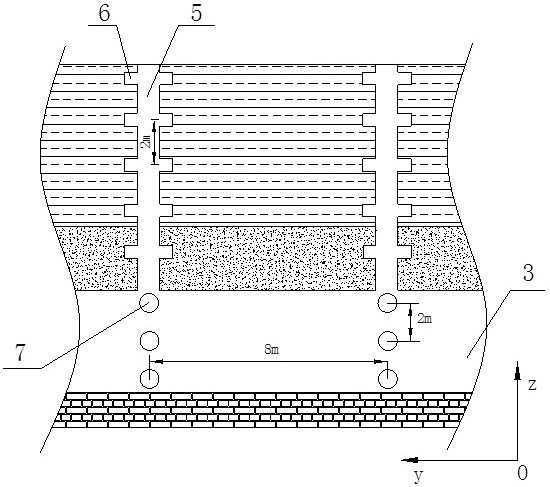

[0039] Specifically, the non-destructive quantitative test method of the working surface three-way pilot field, see figure 1 ,include:

[0040] S101, according to the mining thickness, the depth, the length of the working surface, estimates the monitoring height range of the toner stress field Z direction;

[0041] In the specific implementation process, generally monitored high range is the basic top plate rock format...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com