Pyramid lattice reinforced cavity type underwater sound absorption structure

A technology of lattice structure and pyramid, which is applied in the direction of sound-emitting devices and instruments, to achieve excellent sound absorption performance, improve mechanical properties, and good water pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

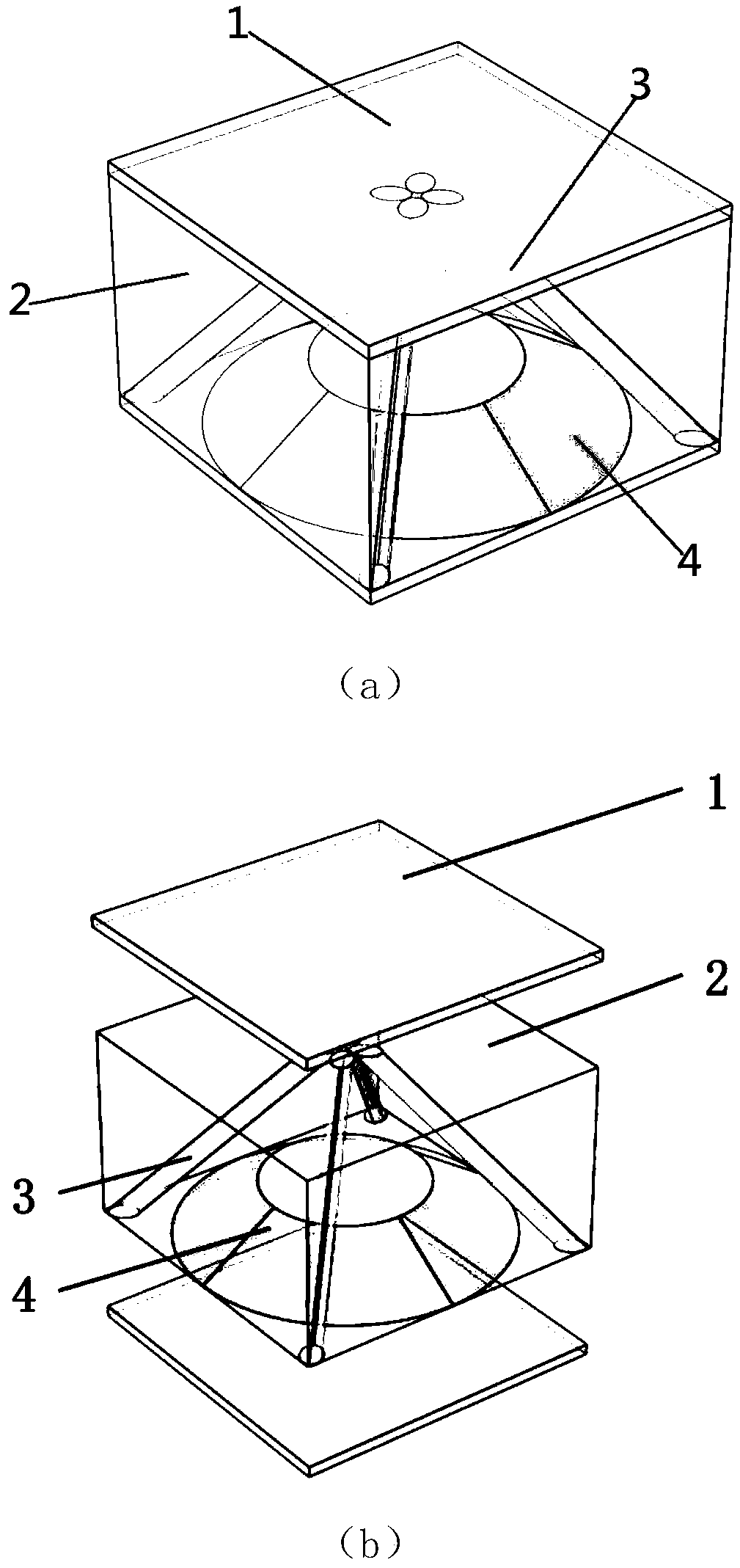

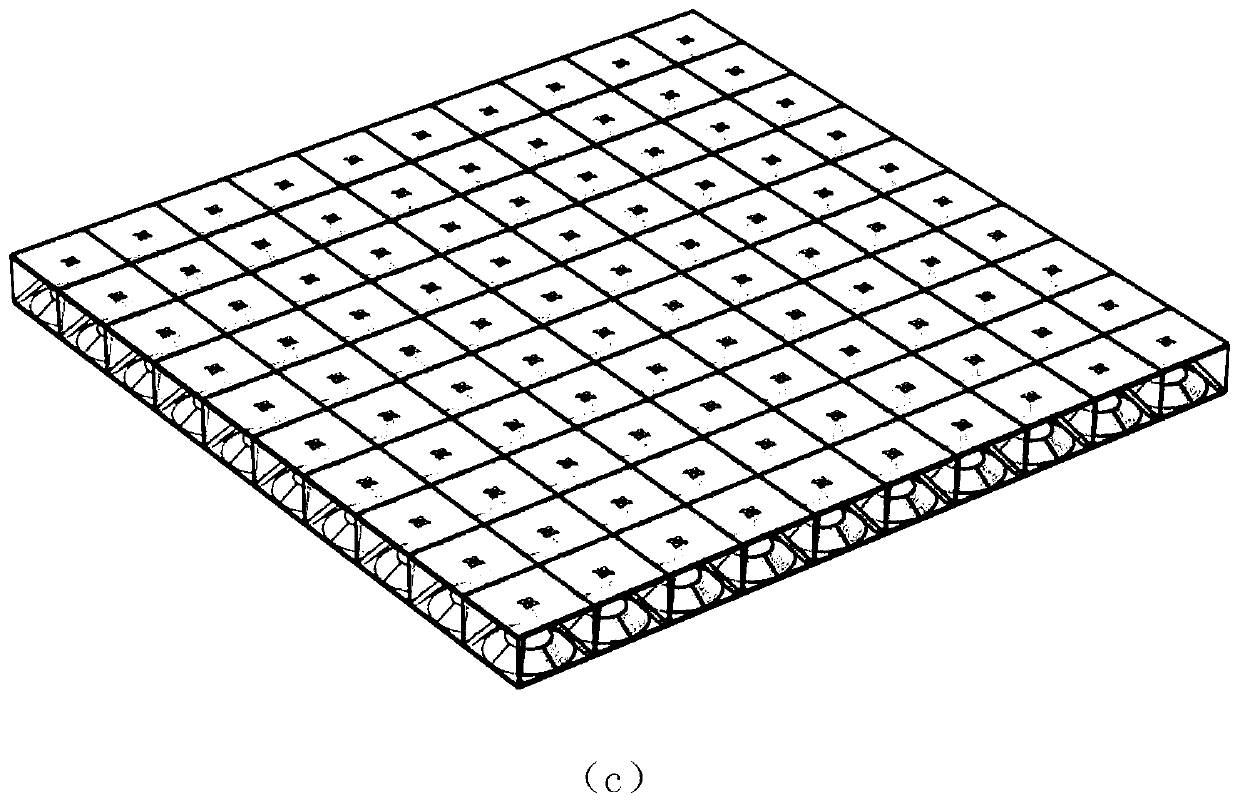

Method used

Image

Examples

Embodiment 1

[0055] The thickness of the panel is 1.5mm, the thickness of the damping layer is 23mm, the cell side length is 40mm, the radius of the diagonal rod is 1.5mm, the length of the diagonal rod is 33mm, the angle between the diagonal rod and the upper and lower panels is 45°, the radius of the upper surface of the cavity is 5mm, and the lower surface of the cavity Radius 20mm, cavity height 5mm.

Embodiment 2

[0057] The thickness of the panel is 2mm, the thickness of the damping layer is 35mm, the cell side length is 60mm, the radius of the diagonal rod is 2mm, the length of the diagonal rod is 50mm, the angle between the diagonal rod and the upper and lower panels is 45°, the radius of the upper surface of the cavity is 15mm, and the radius of the lower surface of the cavity is 30mm , The cavity height is 10mm.

Embodiment 3

[0059] The thickness of the panel is 2.5mm, the thickness of the damping layer is 27mm, the cell side length is 50mm, the radius of the diagonal rod is 2.5mm, the length of the diagonal rod is 38mm, the angle between the diagonal rod and the upper and lower panels is 45°, the radius of the upper surface of the cavity is 10mm, and the lower surface of the cavity Radius 25mm, cavity height 7.5mm.

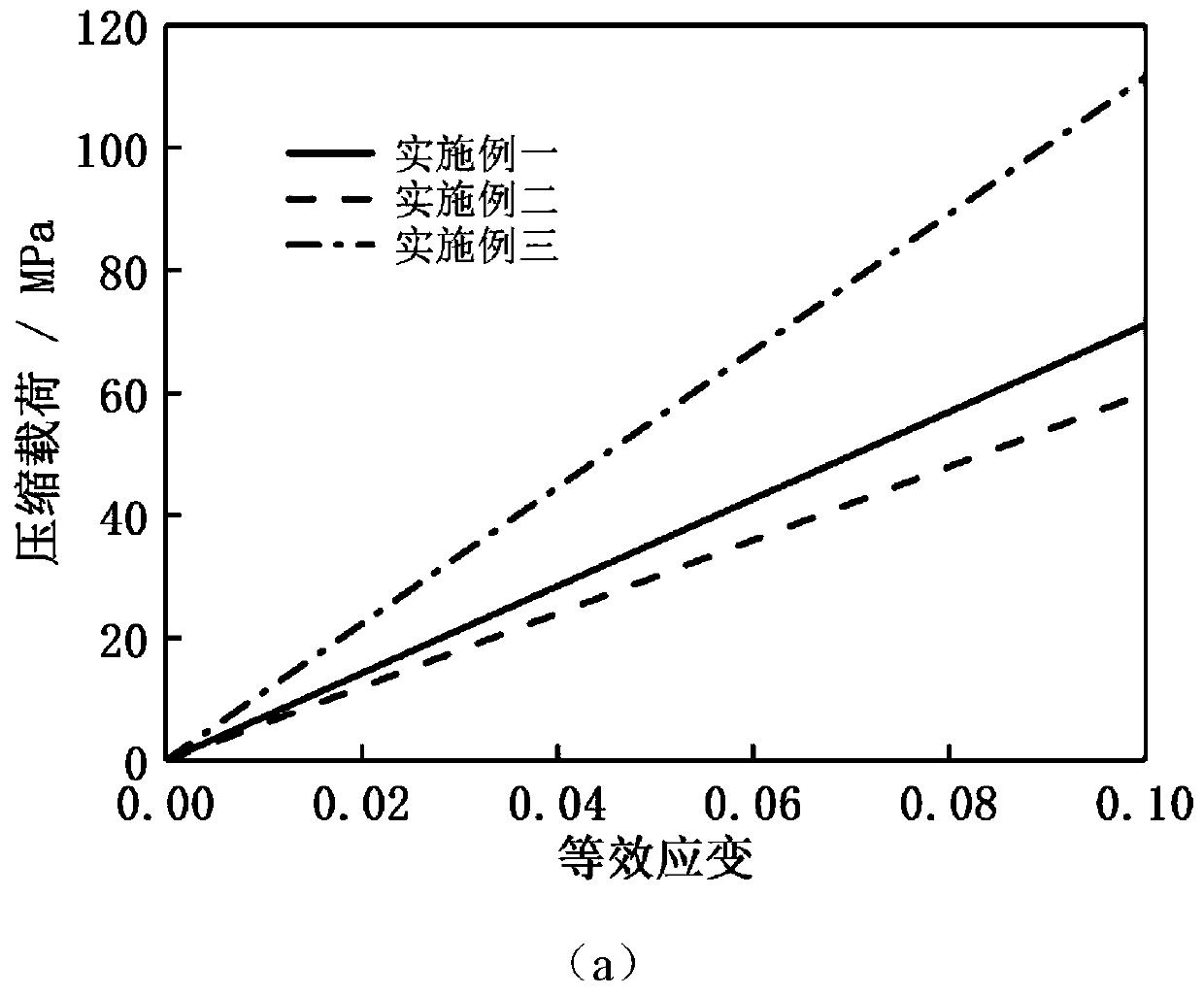

[0060] Adopt above-mentioned material and structure dimension to carry out numerical simulation, the result that provides embodiment is as follows:

[0061] In terms of the mechanical properties of the present invention, please refer to figure 2 (a) is the relationship between the compressive load and the equivalent strain borne by three embodiments of a pyramid-shaped lattice reinforced cavity-type underwater sound-absorbing structure. It can be seen from the figure that the compressive load borne by the present invention has a linear relationship with the equivalent strain, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com