Method for cooling livestock and poultry carcass

A cooling method and carcass technology, applied in the field of livestock and poultry slaughtering, can solve the problems of economic loss, affecting meat quality, inferior meat, etc., and achieve the effects of improving quality and safety, reducing the number of surface microorganisms, and reducing cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

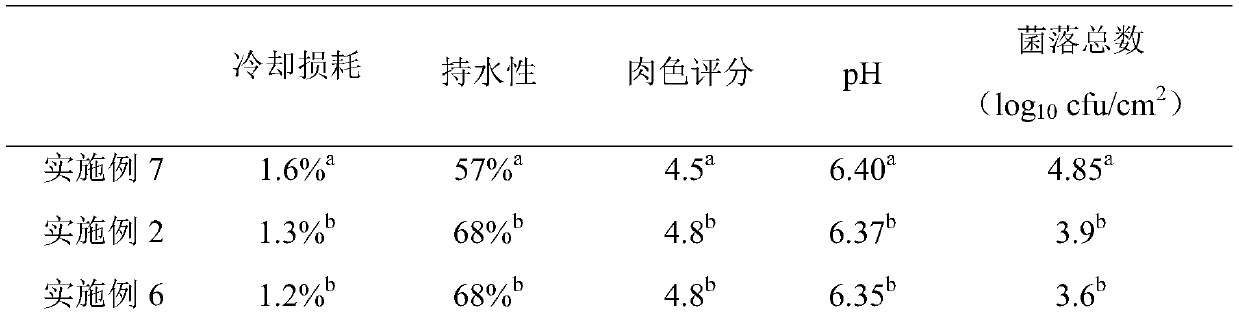

Examples

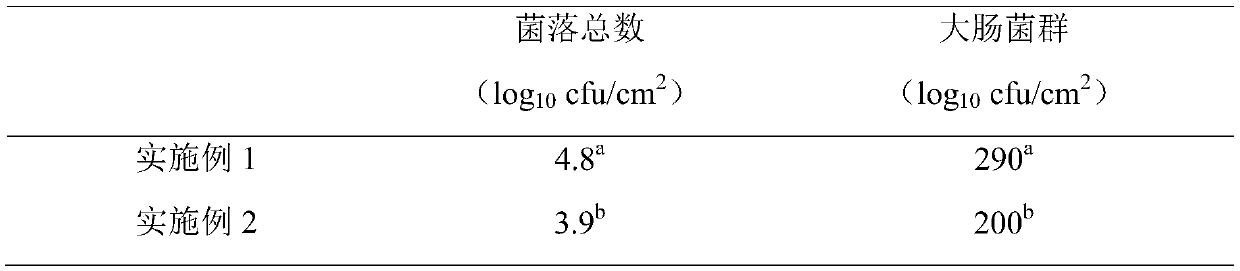

Embodiment 1

[0023] 1) Initial rinse: After the carcass is peeled, rinse with ordinary pressure water at 1 atmosphere for 5 seconds;

[0024] 2) Re-rinsing: to remove the internal organs, and then rinse with ordinary pressure water at 1 atmosphere for 1 min;

[0025] 3) Spraying: Use the mixed solution to spray for 1 min, and the mixed solution is an aqueous solution with a mass fraction of 1.5% lactic acid and 0.8% salt;

[0026] 4) Cooling: sequentially placed at -30°C for 1.5h, placed at 5°C for 8h, placed at 0°C for 14.5h;

[0027] Among them, the water temperature of ordinary pressure water is 20°C.

Embodiment 2

[0029] 1) Initial rinse: After the carcass is peeled, rinse with high pressure water at 1.1 atmospheres for 5 seconds;

[0030] 2) Re-rinsing: remove the internal organs, and then rinse with high-pressure water at 1.1 atmospheres for 0.8 min;

[0031] 3) Spraying: spraying for 0.8min with a mixed liquid, the mixed liquid is an aqueous solution with a mass fraction of 1.5% lactic acid and a mass fraction of 0.8% salt;

[0032] 4) Cooling: Place it at -30℃ for 1 hour, 5℃ for 7.5h, and 0℃ for 14.5h;

[0033] Among them, the temperature of the high-pressure water is 15°C;

[0034] The aperture of the spray nozzle is 0.2mm, and the temperature of the mixed liquid is 5℃

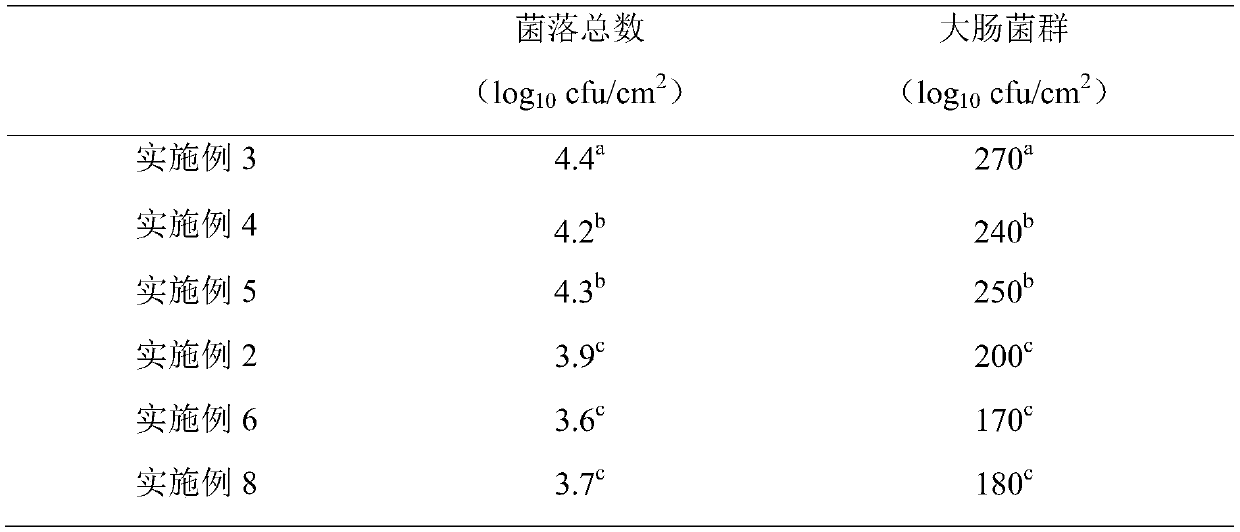

Embodiment 3

[0036] 1) Initial rinse: After the carcass is peeled, rinse with high pressure water of 1.2 atmospheres for 5 seconds;

[0037] 2) Re-rinsing: remove the internal organs, and then rinse with high-pressure water at 1.2 atmospheres for 1 min;

[0038] 3) Spray: Use water to spray for 1 min;

[0039] 4) Cooling: sequentially placed at -30°C for 1.5h, placed at 5°C for 8h, placed at 0°C for 14.5h;

[0040] Among them, the temperature of the high-pressure water is 20°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com