Self-fixing manual cutting device for processing building steel bars

A technology for building steel bars and cutting devices, which is applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. The effect of improving cutting quality, high reliability and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

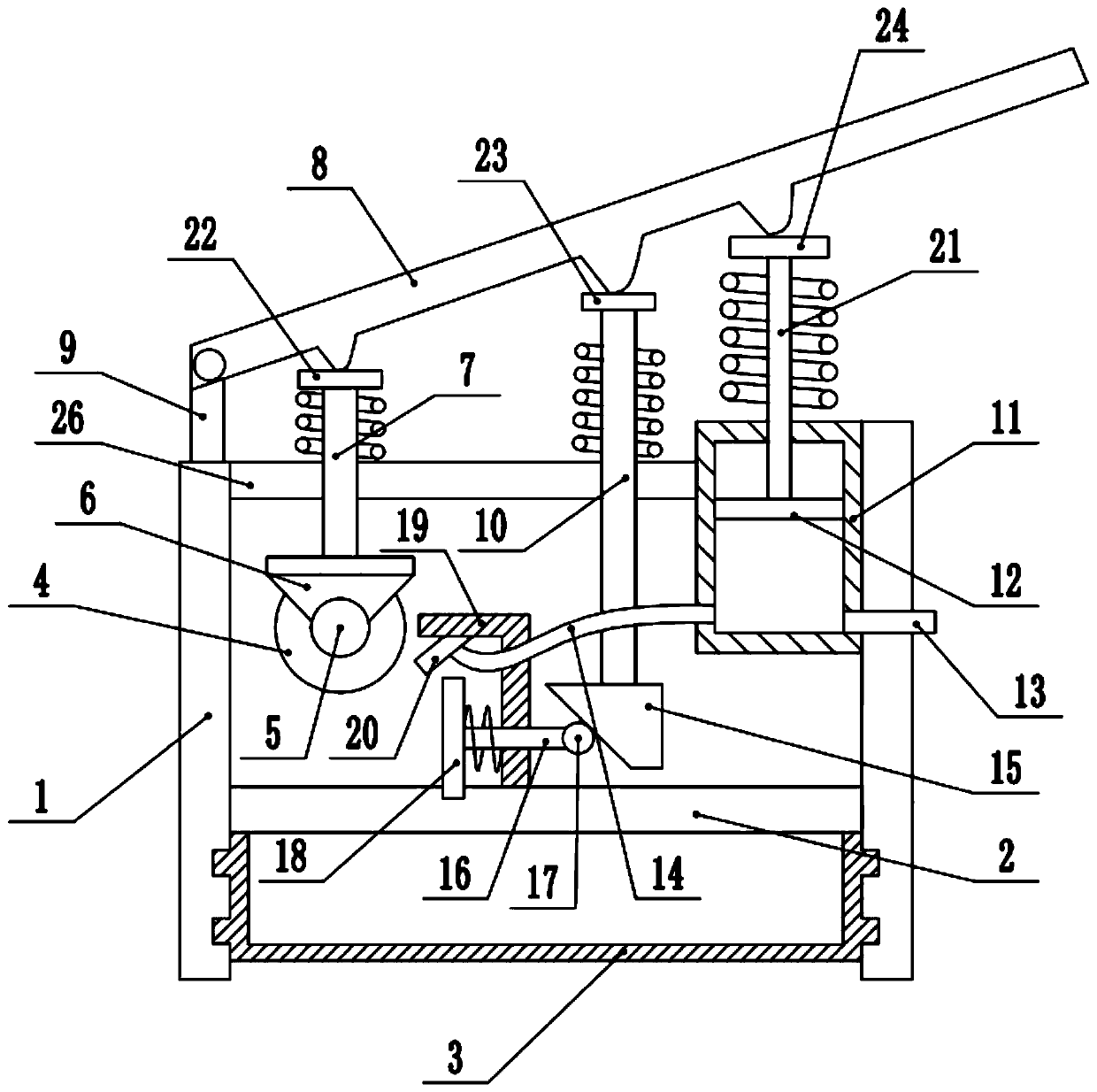

[0028] refer to Figure 1~3 , in an embodiment of the present invention, a self-fixing manual cutting device for processing steel bars for construction, comprising a support frame 1, a workbench 2 is installed in the middle of the lower end of the support frame 1, and a slag storage box 3 is installed at the bottom of the workbench 2, It is used to collect waste slag generated during the cutting process. The two ends of the slag storage box 3 are slidably connected to the bottom end of the support frame 1. A fixing plate 26 is installed on the top of the support frame 1. A cutting column 7 is installed in the middle of the left side of the fixing plate 26. The lower end of the cutting column 7 is equipped with a motor base 6, and the lower end of the motor base 6 is equipped with a cutting motor 5, which is used to drive the cutting wheel 4 to cut and realize the cutting effect. The output end of the cutting motor 5 is equipped with a cutting wheel 4, and the fixed plate 26 Th...

Embodiment 2

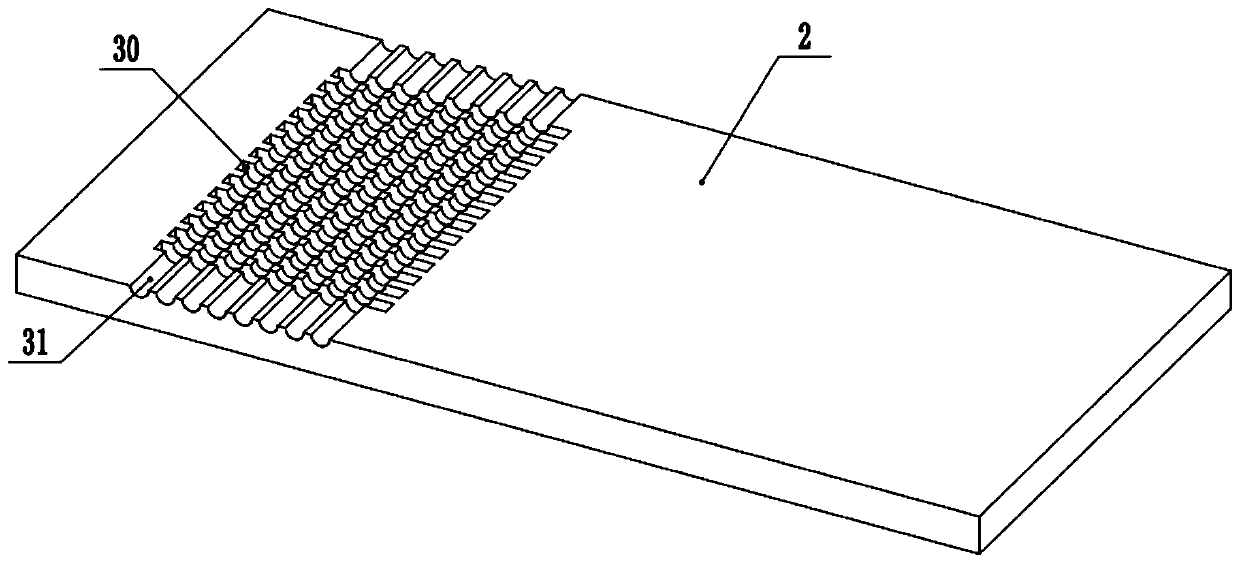

[0030] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that several cutting grooves 30 are provided on the left side of the workbench 2, so that the cutting wheel 4 can give way during the cutting process. , the vertical position of the cutting groove 30 is equipped with a reinforcement groove 31, which is used for placing the reinforcement to be cut.

[0031]In the present invention, when working, the steel bar is placed on the steel bar groove 31 on the workbench 2, and then the cutting motor is started. During the cutting of steel bars, at the same time, the lifting shaft 7 moves downward, and the guide column 16 drives the clamping block 18 to move towards the steel bar through the action of the lifting block 15, so as to realize the extrusion and fixing of the steel bars, and at the same time, the exhaust plate 12 moves along the row The air box 11 moves downwards, and the gas is sprayed out thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com