Automatic wire tightening mechanism of wire cutting machine

A wire cutting machine and automatic technology, applied in the field of mechanical processing, can solve the problems of reducing cutting efficiency, prone to broken wires, poor chip removal, etc., and achieve the effects of simple structure, improved cutting efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

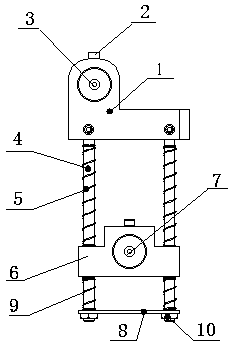

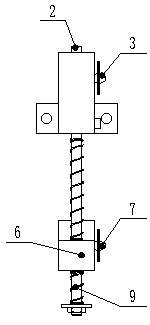

[0016] Specific examples: such as figure 1 , figure 2 As shown, the support seat 1 is connected with the wire cutting body through a thread pair, and the guide groove on the upper guide wheel 3 is on the same plane as the guide wheel groove on the wire cutting body, and the support seat 1 is threaded. The pair is connected to the sliding rod 4, the upper guide wheel 3 is installed on the support seat 1 through the bearing seat, the bearing seat is tightened by the set screw 2, the connecting piece 8 is installed on the lower part of the sliding rod 4, the position of the connecting piece 8 can be adjusted by the adjusting nut 10, The sliding support 6 is slidingly matched with the sliding rod 4. There is an upper spring 5 at the upper end of the sliding support 6, and a lower spring 9 at the bottom. The function of the upper spring 5 can keep the tension of the molybdenum wire constant. When the wire breaks suddenly, the impact force of the sliding support 6 on the connectin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap