Free-form optical component surface shape error on-machine detecting device and method based on white light confocal theory

A technology of white light confocal and optical components, which is applied in the direction of using optical devices, measuring devices, measuring/indicating equipment, etc., can solve the problems of poor efficiency, easy damage to the surface of optical components by probes, and low precision, so as to save time and improve Ultra-precision machining efficiency and the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

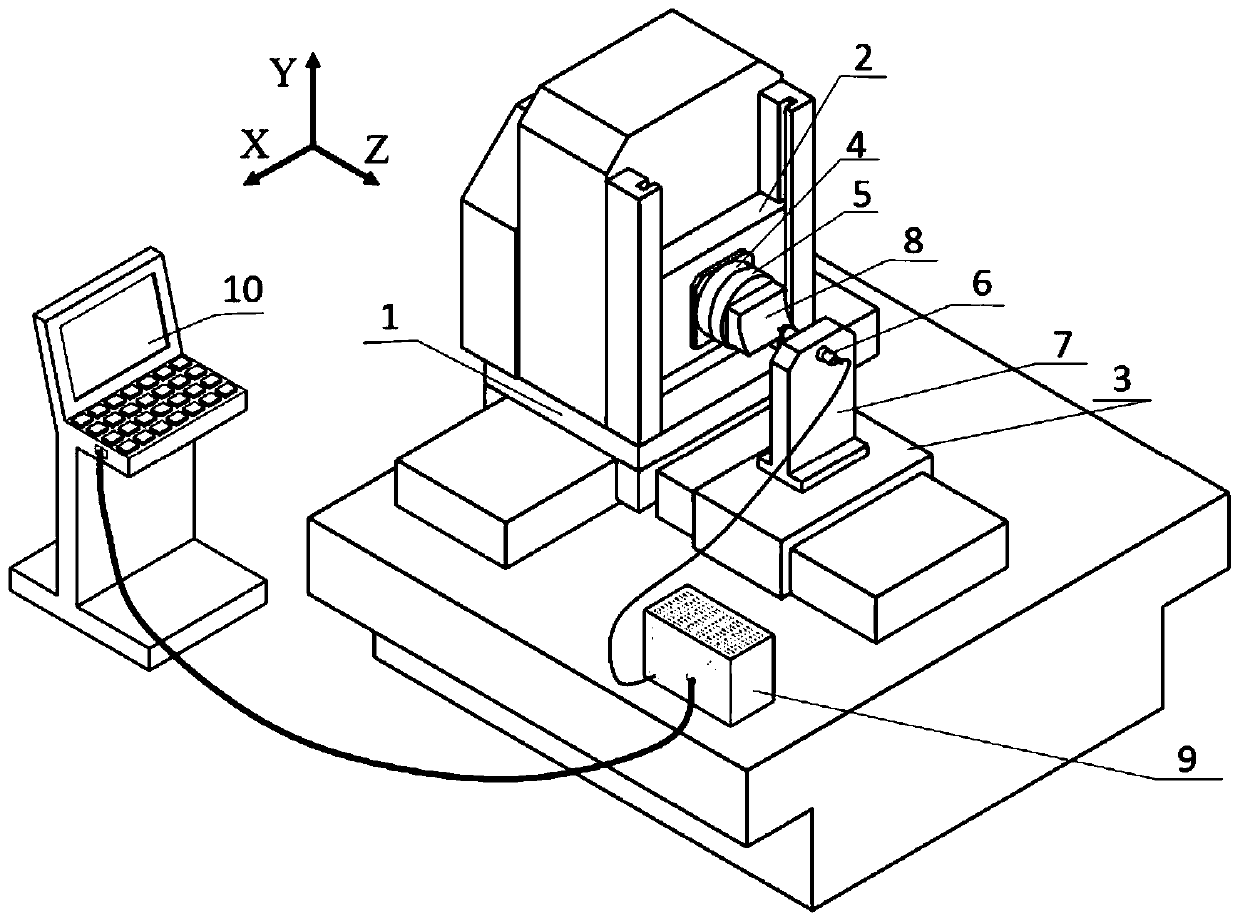

[0046] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the free-form surface optical element surface shape error detection device based on the principle of white light confocal in this embodiment, the detection device includes X-axis moving stage 1, Y-axis moving stage 2, Z-axis moving stage 3, Rotary shaft 4, vacuum chuck 5, white light confocal probe 6, fixture 7, controller 9 and machine tool industrial computer 10;

[0047] The X-axis and the Z-axis are two axes on the horizontal plane, and the Y-axis is the longitudinal axis perpendicular to the horizontal plane. The rotation axis 4 is installed on the Y-axis moving table 2, and a vacuum chuck 5 is installed on the rotation axis 4. The component 8 is installed on the vacuum chuck 5, the white light confocal measuring head 6 is installed on the Z-axis moving table 3 through the fixture 7, the outgoing light of the white light confocal measuring head 6 is parallel to the Z-axis...

specific Embodiment approach 2

[0048] Embodiment 2: In this embodiment, Embodiment 1 is further described. The measuring range of the white-light confocal probe 6 is -75-75 μm, and the inclination range of the surface of the free optical element that can be measured is ±42°.

specific Embodiment approach 3

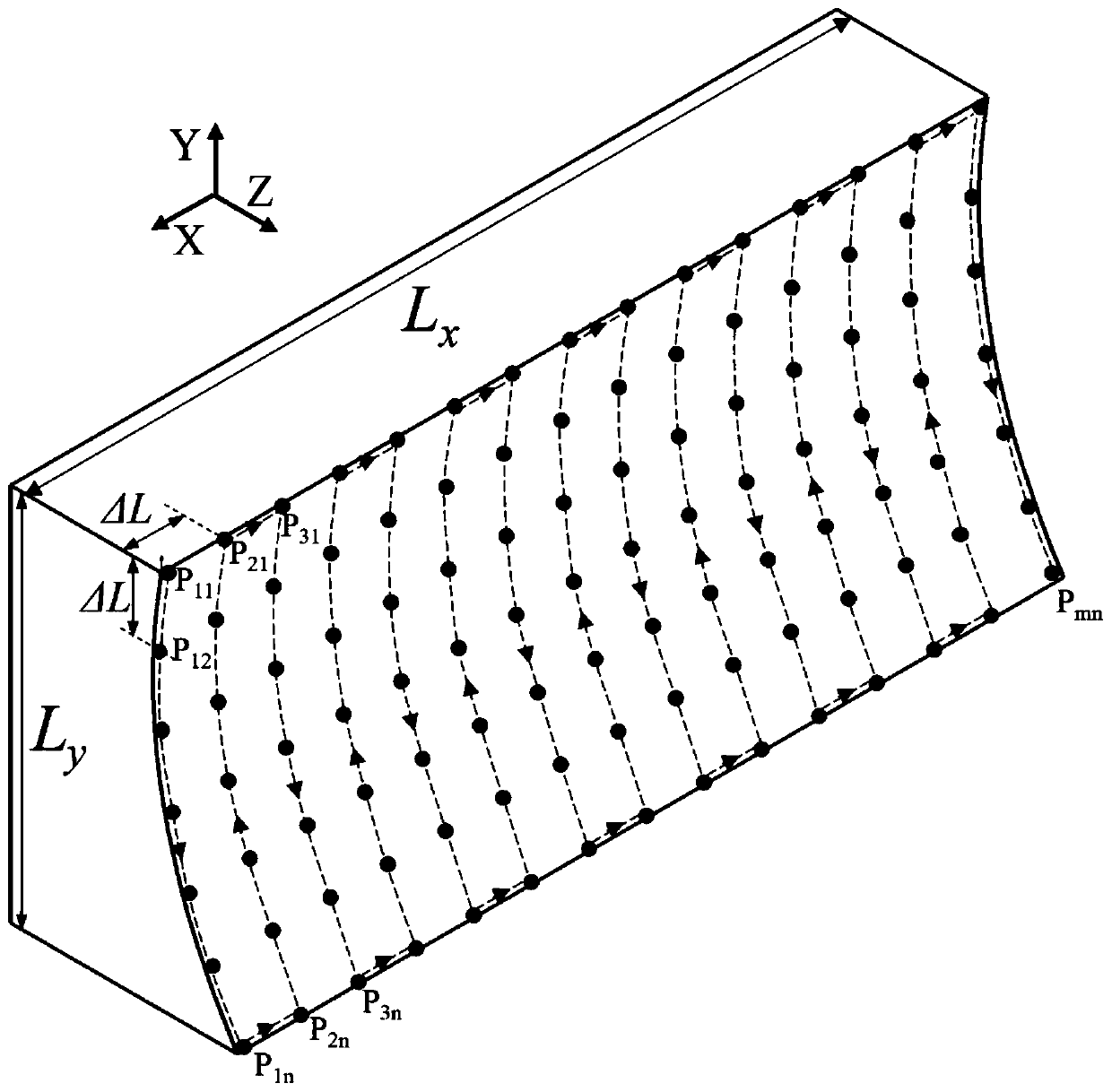

[0049] Specific implementation mode three: the following combination figure 2 Describe this embodiment, the on-machine detection method for the surface error of free-form surface optical elements based on the principle of white light confocal described in this embodiment, the specific process of the detection method is:

[0050] S1. Adjust the X-axis moving stage 1 and the Y-axis moving stage 2, so that the white light confocal probe 6 is facing the point on the upper left edge of the free-form surface optical element 8 to be measured, and adjust the white light confocal measuring head 6 through the Z-axis moving stage 3 The distance from the free-form surface optical element 8 to be measured is such that the output detection data of the white light confocal probe 6 is 0;

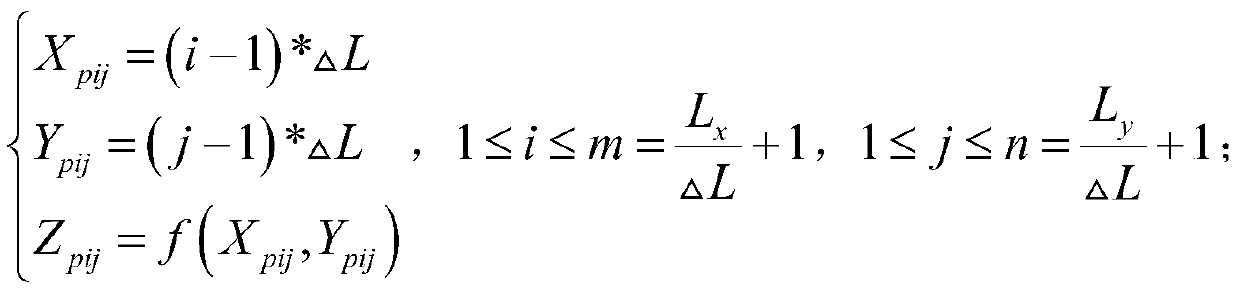

[0051] S2. According to the free-form surface description equation, generate a three-dimensional coordinate point sequence with equal intervals between the X coordinate and the Y coordinate, insert the gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com