Oxygen-free copper microstructure functional surface jet flow polishing solution and polishing method

A technology of polishing liquid and microstructure, which is applied in the direction of polishing compositions containing abrasives, etc., and can solve the problems of easy oxidation, need for improvement, and low removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

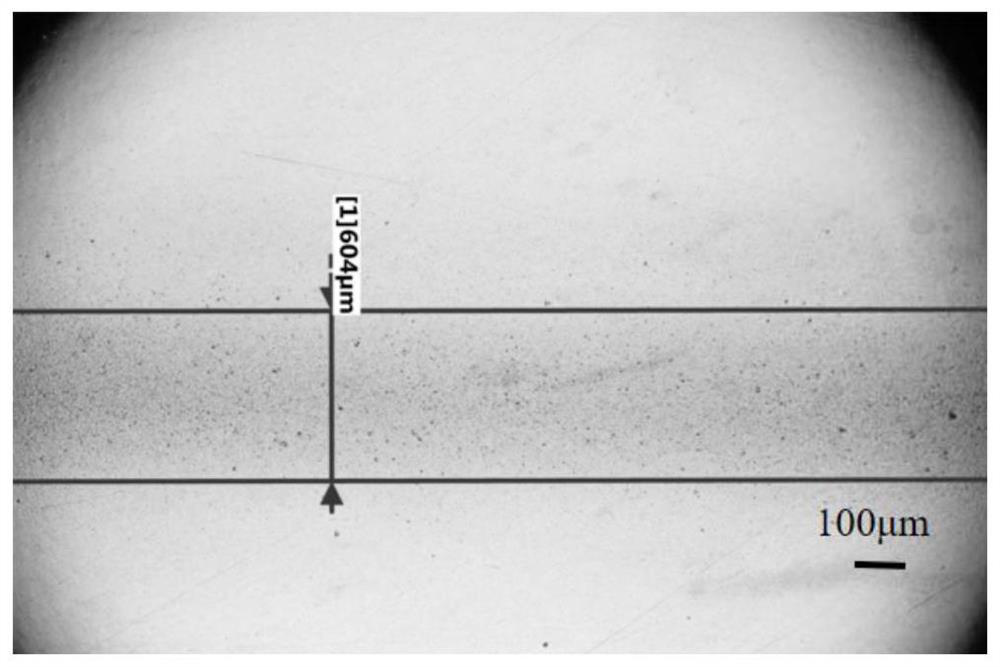

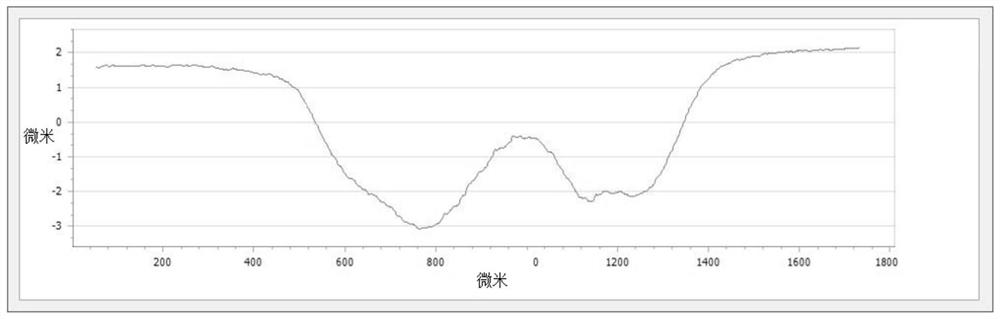

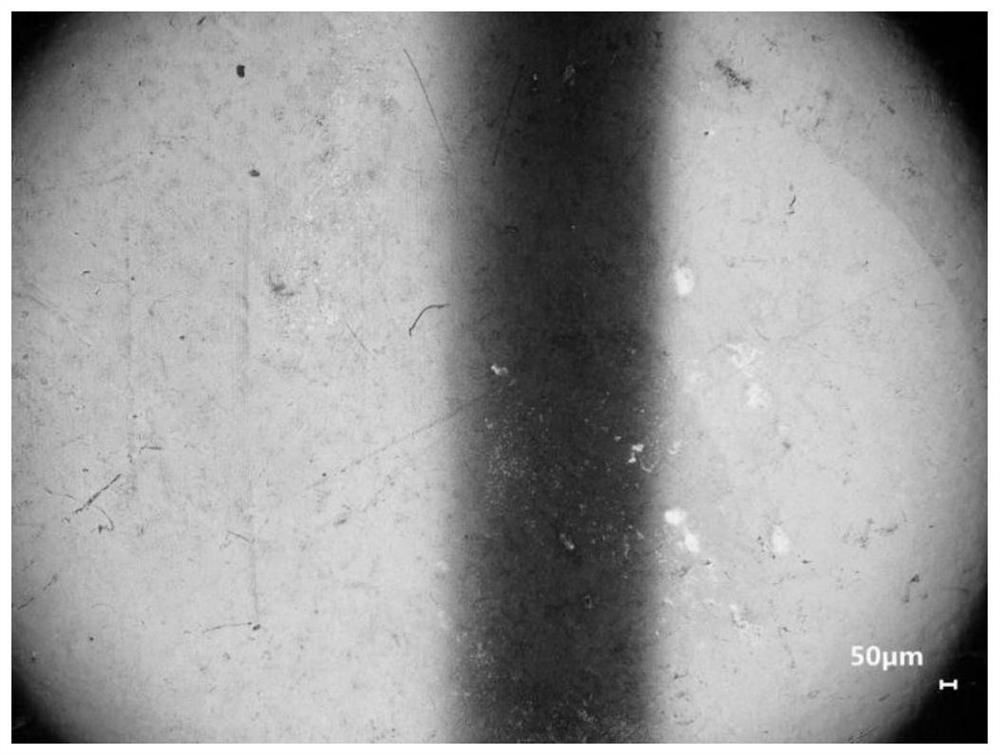

[0041] Add 20wt% of 200nm silicon oxide particles, 0.1wt% perchloric acid, 0.5wt% ethylenediaminetetraacetic acid, 0.5wt% sodium hydroxide, and 0.005wt% liquiritin to the deionized water in sequence, and keep stirring until they are evenly mixed. After uniform mixing, a jet polishing liquid is formed, and the pH of the polishing liquid is 6.8. The oxygen-free copper surface is polished by jet polishing, after polishing, the surface is cleaned and dried. The surface defects (scratches and pits) were observed with an optical microscope, and the polishing depth and surface roughness of the polished samples were measured with a white light interferometer. The results are shown in Table 1.

Embodiment 2

[0043] The remaining operating steps are the same as in Example 1, except that the contents of each component in the polishing solution are: 10 wt% of alumina particles with a diameter of 5000 nm, 10 wt% of hydrogen peroxide, 0.1 wt% of aspartic acid, 1 wt% of ammonia water, and 0.001 wt% of puerarin wt%, stirring continuously until it is uniformly mixed, and then a jet polishing fluid is formed after uniform mixing, and the pH of the polishing fluid is 7.5. The surface defects (scratches and pits) were observed with an optical microscope, and the polishing depth and surface roughness of the polished samples were measured with a white light interferometer. The results are shown in Table 1.

Embodiment 3

[0045] The remaining operating steps are the same as in Example 1, except that the contents of each component in the polishing solution are: 1 wt% of 1000nm diamond particles, 0.2 wt% of sulfuric acid, 1 wt% of glycine, 1 wt% of potassium hydroxide, and 0.002 wt% of delphinidin wt%, stirring continuously until it is uniformly mixed, and then a jet polishing fluid is formed after uniform mixing, and the pH of the polishing fluid is 8.0. The surface defects (scratches and pits) were observed with an optical microscope, and the polishing depth and surface roughness of the polished samples were measured with a white light interferometer. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com