Multi-station integrated repair method for micro-defects on the surface of large-aperture fused silica optical elements

A technology of optical components and repair methods, which is applied in the field of engineering optics, can solve the problems of micro-defect repair and image processing information cannot be effectively shared, and achieve the effects of avoiding damage to optical components, improving efficiency, and improving the effect of micro-defect repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

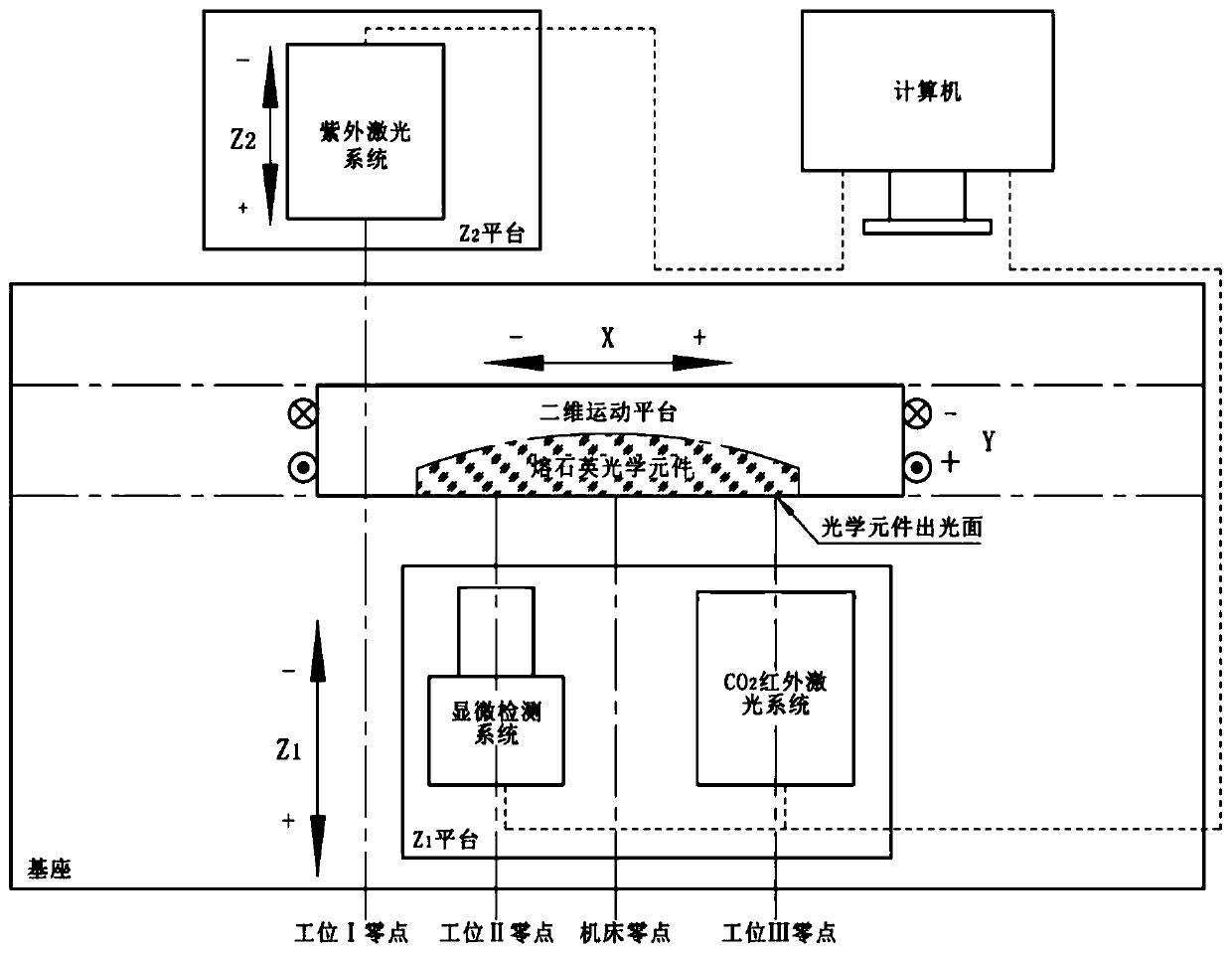

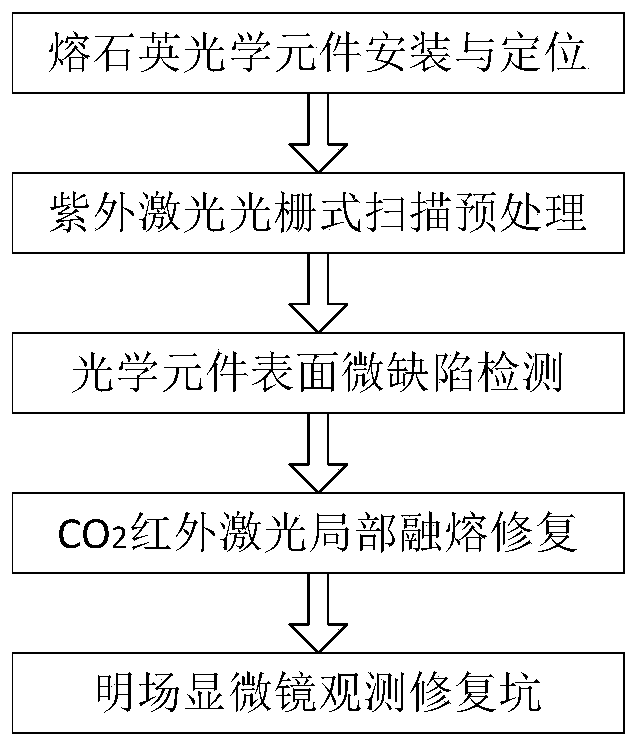

[0065] The optically polished Corning7980 fused silica optical elements are available in various sizes such as 50mm×50mm×5mm, 100mm×100mm×5mm and 430mm×430mm×10mm, according to such as image 3 The process is carried out to verify the multi-station integrated repair function of optical components.

[0066] Step 1. Fused silica optical element installation and positioning

[0067] After starting the system, carry out the zero return operation to establish the coordinate system of the machine tool system, that is, the absolute coordinate system.

[0068] Under the absolute coordinate system, move the two-dimensional motion platform of the machine tool to the optical element installation station, and install the optical element. The fused silica optical element is a hard and brittle material. It is a relatively complicated installation process to ensure that it will not be damaged or introduced surface contamination during the installation process. The installation process will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com