Test frame device for steel grits splashing trend for sand blasting machine equipment production

A technology of sandblasting machine and test stand, which is applied to used abrasive processing devices, metal processing equipment, grinding/polishing equipment, etc., can solve the waste of useless steel sand, cannot be tested by shot blasting machine, and cannot be pre-tested. and other problems, to achieve the effect of uniform quantity and reasonable structure of sandblaster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

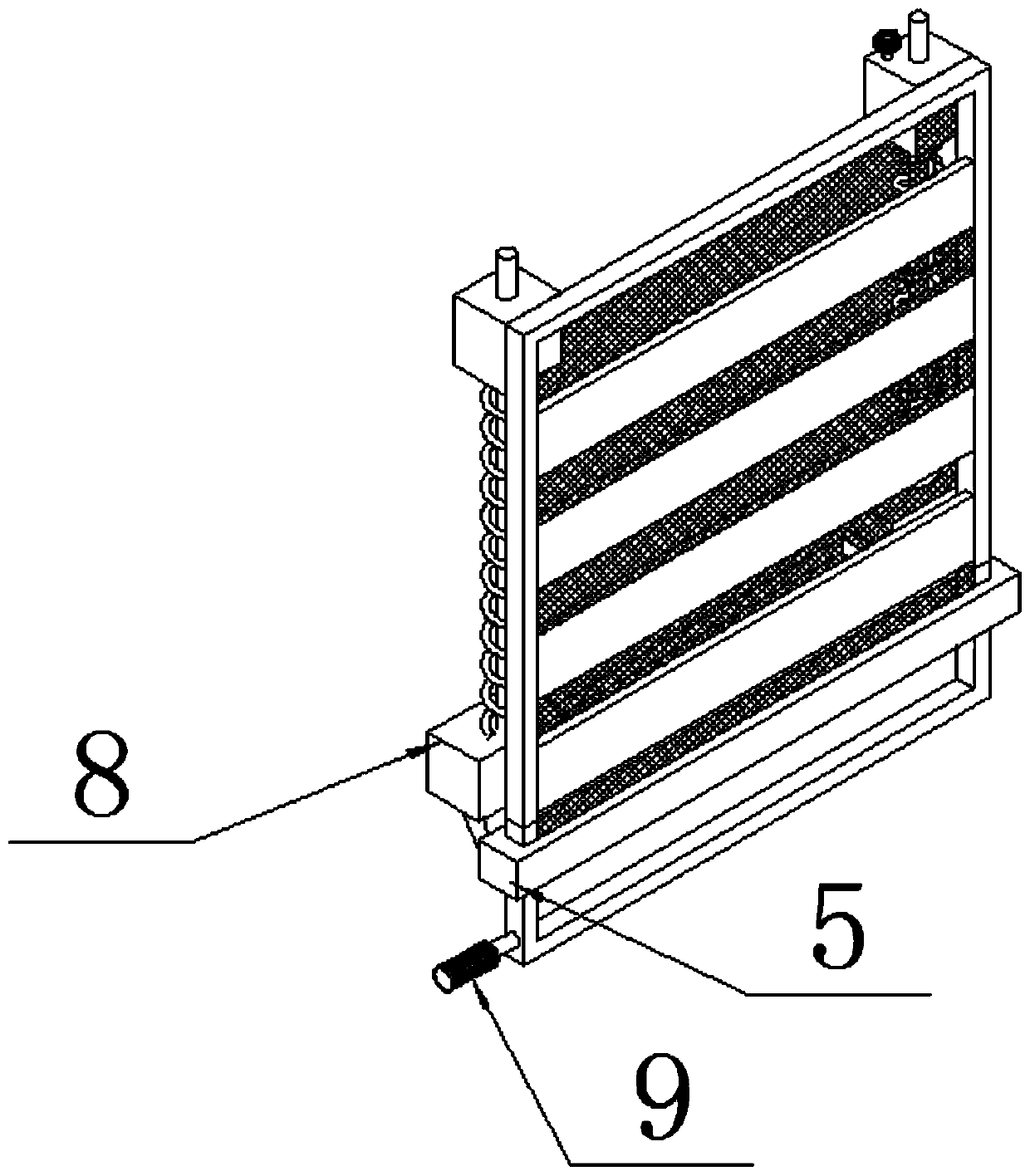

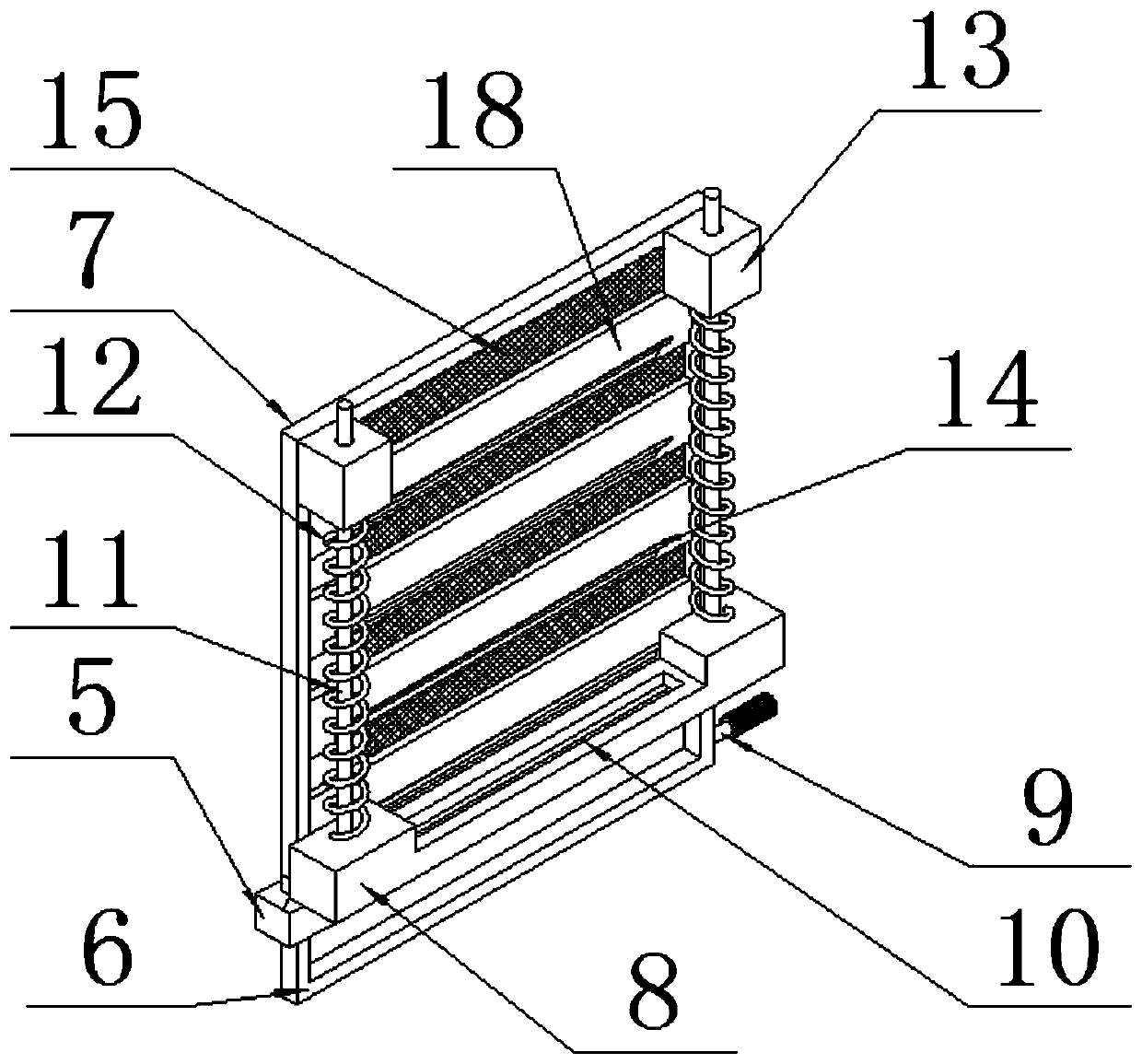

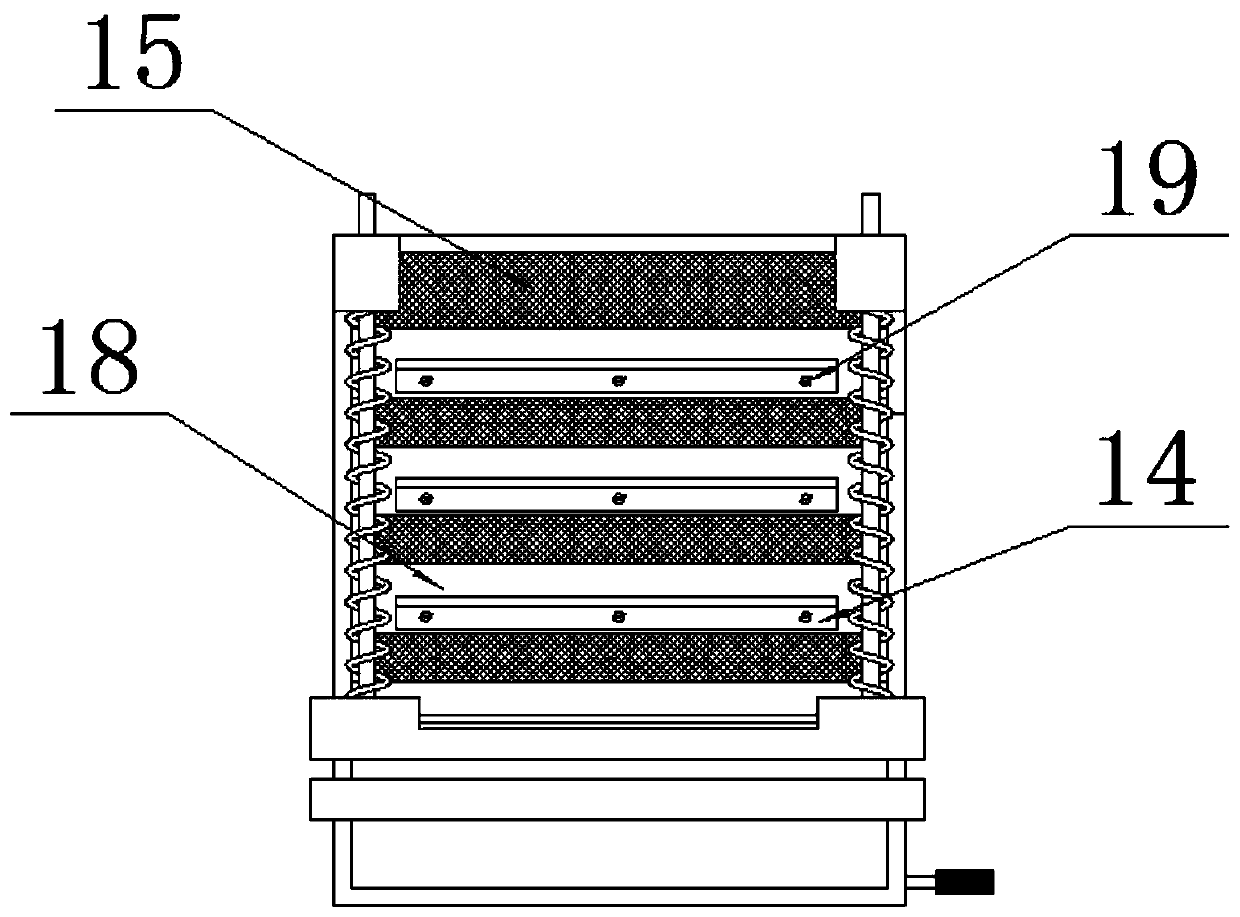

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The invention provides a test frame device for the direction of steel grit splashing used in the production of sandblasting machine equipment, comprising: a sandblasting machine main body 1, a feed port 2, a top cover 3, a hinged door 4, a sliding seat 5, a stopper 6, and a frame 7. Mounting seat 8, lever 9, mounting groove 10, guide rod 11, return spring 12, guide pressure seat 13, sand board 14, observation net 15, lock post 16, lock hole 17, welding plate 18 and threaded plug 19; the top surface of the sliding seat 5 is near the inner position, and a mounting seat 8 is installed by tilting the outer edge; the two sides of the top surface of the mounting seat 8 are bonded and installed with a cylindrical rod structure in a vertical manner. guide rod 11, and a guide rod 11 is also sleeved on the outside of the guide rod 11; the frame 7 is a rectangular outer frame structure, and a guide press seat 13 is also in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap