Continuous production line for plastic battery cases

A production line and battery technology, applied in the directions of packaging/bundling items, packaging, wrapping items, etc., can solve the problems such as the lack of automatic trimming and detection of battery boxes, the lack of automatic packaging of battery boxes, and the large workload of workers. The process is efficient and reasonable, avoiding unstable falling, and the effect of high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

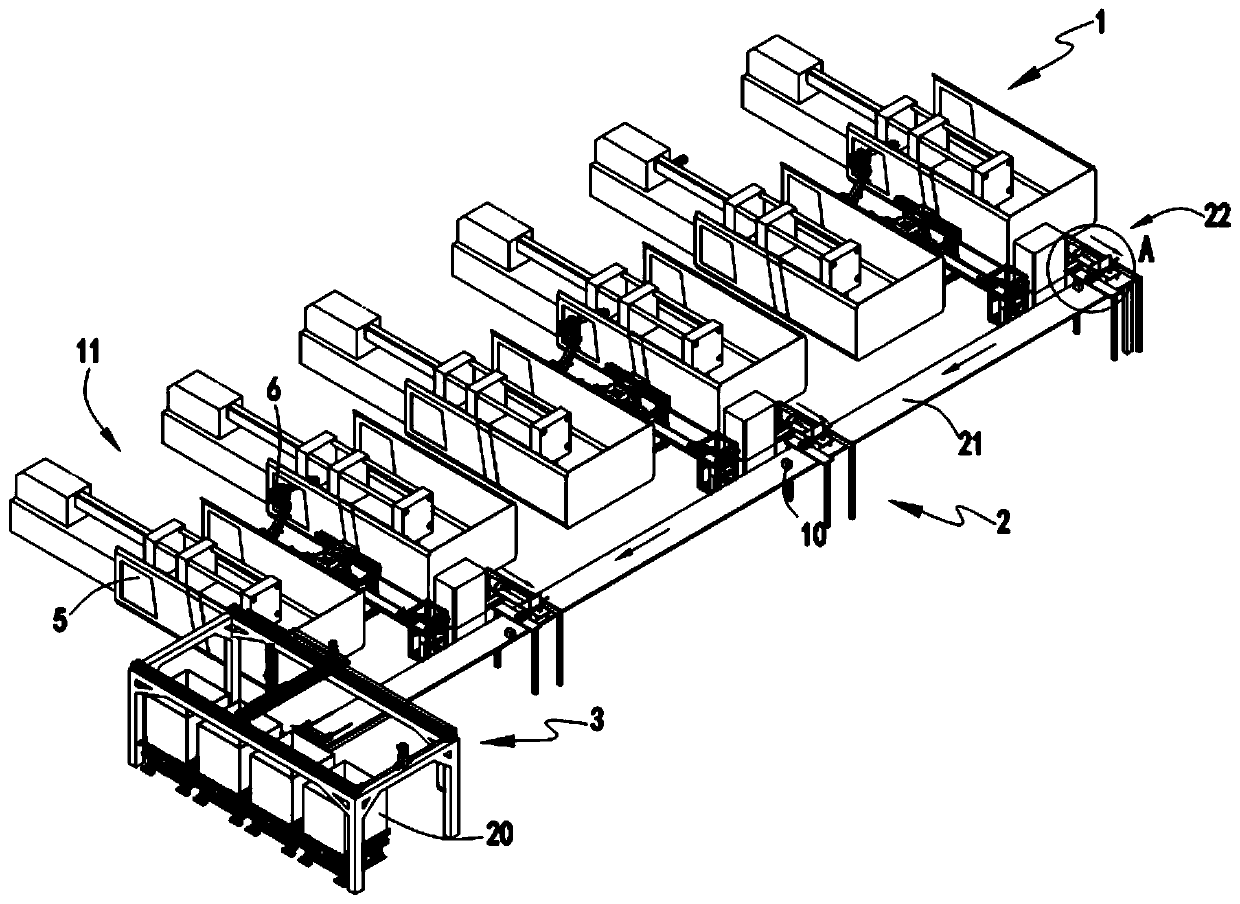

[0068] like Figure 1 to Figure 21 As shown, a battery plastic case continuous production line includes a molding part 1, a transfer transmission part 2 and a packing part 3;

[0069] The molding section 1 includes several molding modules 11, the transfer transmission section 2 includes a conveying line 21 and a transfer device 22 arranged between the conveying line 21 and each molding module 11, and is automatically processed and trimmed by the molding module 11 , The battery box 10 after detection and scrapping is transferred to the transfer device 22, transferred to the top of the conveying line 21 by the transfer device 22 and vertically moved down to the conveying line 21 after completing a 90-degree turn over the conveying line 21;

[0070] The forming module 11 is arranged along the conveying direction of the conveying line 21, and the transfer device 22 corresponding to the previous forming module 11 transfers the formed battery case 10 to the conveying line 21, and th...

Embodiment 2

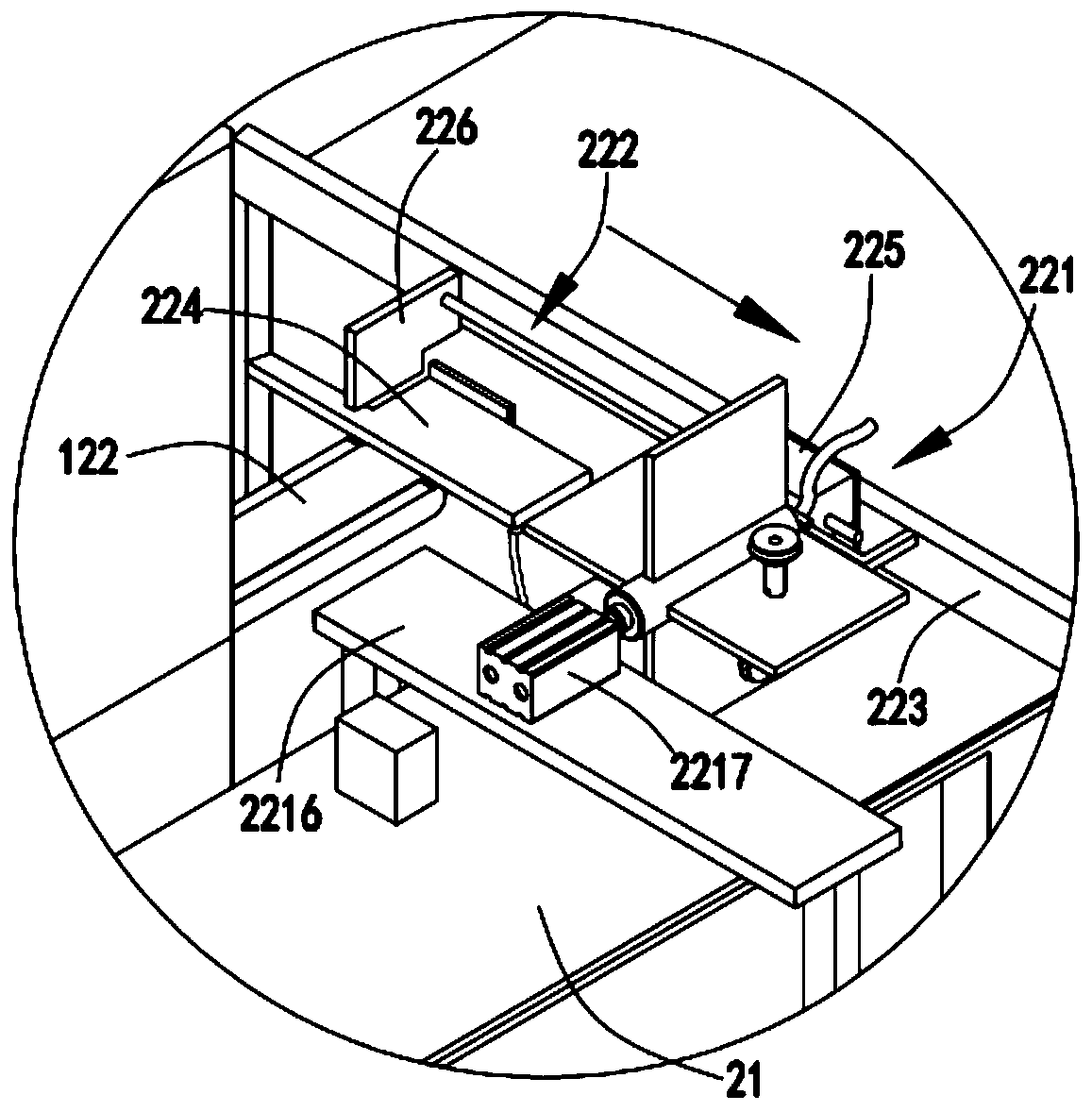

[0097] like Figure 5 to Figure 12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: further, the turning assembly 2211 includes a mandrel 2213 fixed on the bracket c2231, a rotating shaft 2214 sleeved on the mandrel 2213, and along the circumferential direction of the rotating shaft 2214 The support block 2215 arranged on the rotating shaft 2214 in an array, the support 2216 and the rotating member 2217 arranged on the support 2216 for driving the rotating shaft 2214 to rotate around the core shaft 2213,

[0098] The adsorption assembly 2212 includes a sliding rod 2218 fixed on the surface of the support block 2215 and a sliding sleeve 2219 slidably sleeved on the sliding rod (2...

Embodiment 3

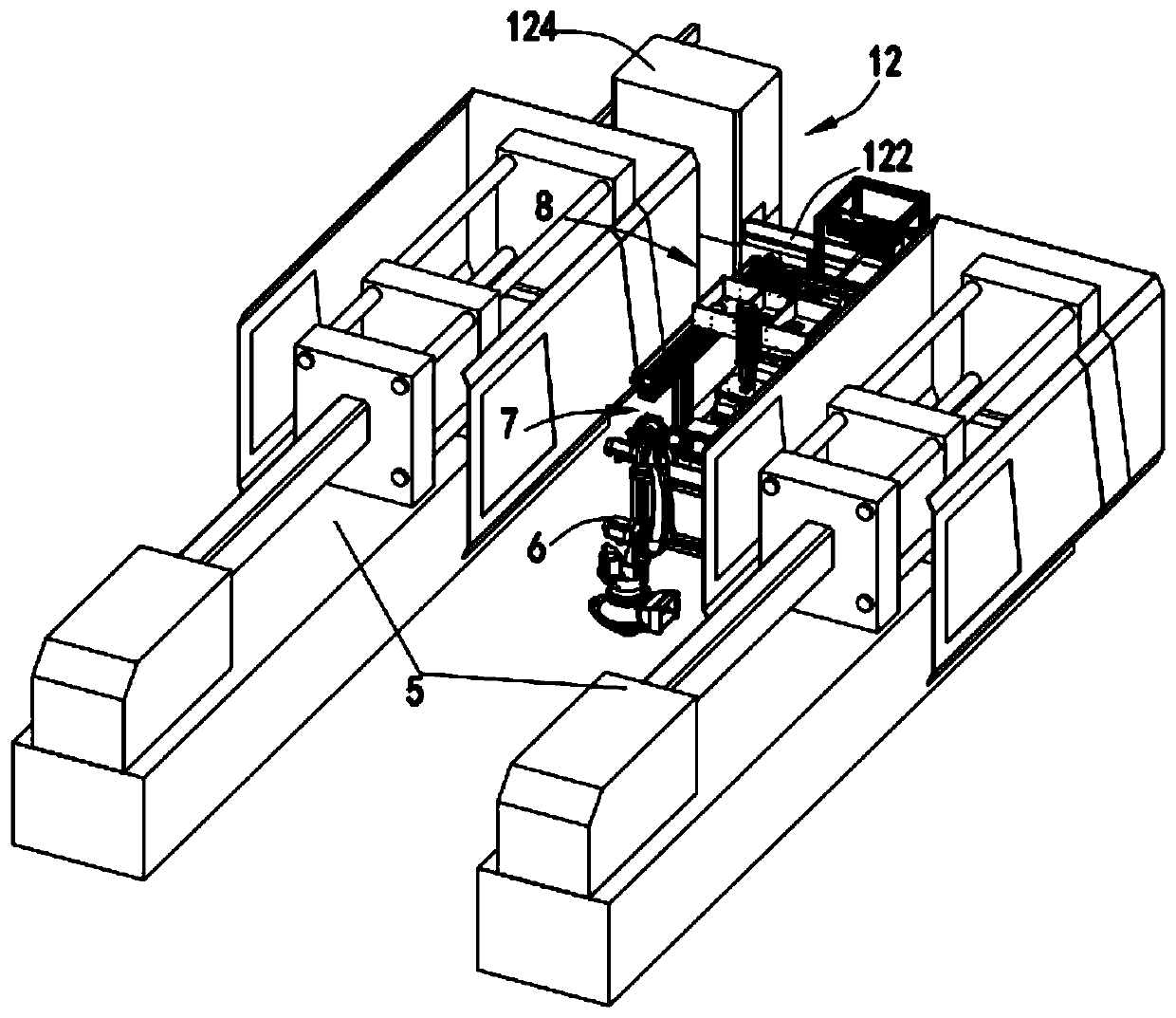

[0102] like Figure 16 and Figure 19 , wherein the same or corresponding components as those in Embodiment 2 use the corresponding reference numerals as in Embodiment 2. For the sake of simplicity, only the differences from Embodiment 2 will be described below. The difference between the third embodiment and the second embodiment is that further, the four corners of the positioning groove 713 are provided with circular arc-shaped through grooves 715, and the upper ends of the four sides are provided with guide limiters. Bit block 716.

[0103] The four corners of the positioning slot are provided with arc-shaped through slots so that the four corners of the battery box and the inner wall of the positioning slot can be avoided from frictional collision during the process of putting the battery box into the positioning slot, which can further ensure The quality of the battery case.

[0104] The working process is as follows:

[0105] Injection molding machine 5 injects and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com