Full-load sensitive controlled scraper type garbage compressor control method and circuit

A technology of garbage compressor and control method, applied in the direction of press, garbage conveying, garbage collection, etc., can solve the problems of energy waste, inability to adjust the pressure of hydraulic system, lack of load-sensitive control function, etc., to prevent excessive compression, Guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

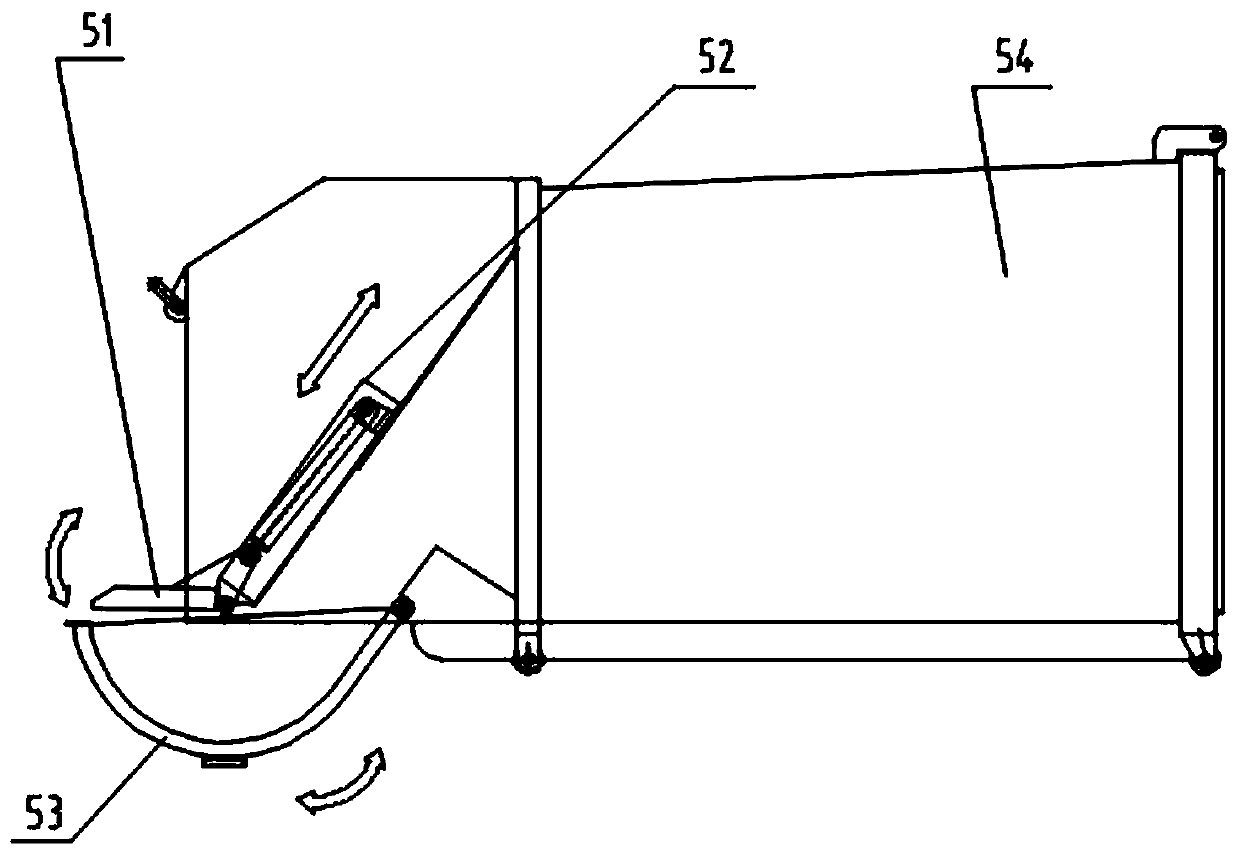

[0059] Such as figure 1 As shown, the scraper type garbage compressor is composed of a scraper 51, a slide 52, a hopper 53, and a box body 54. The scraper 51 is arranged at the front end of the feed port of the garbage compressor; the slide 52 is connected with the scraper 53, and the hopper 53 is arranged on Below the scraper 51 and the slide plate 52, the scraper 51, the slide plate 52, and the hopper 53 form the front end working area of the garbage compressor, and the box body 54 is fixedly arranged behind the working area as a garbage storage area of the garbage compressor.

[0060] The scraper garbage compressor adopts PLC control system as the core system of its automatic operation. The system has three parameters of weight, pressure and temperature as the core to realize the system judgment of the overall work of the garbage compressor and the operation requirements. .

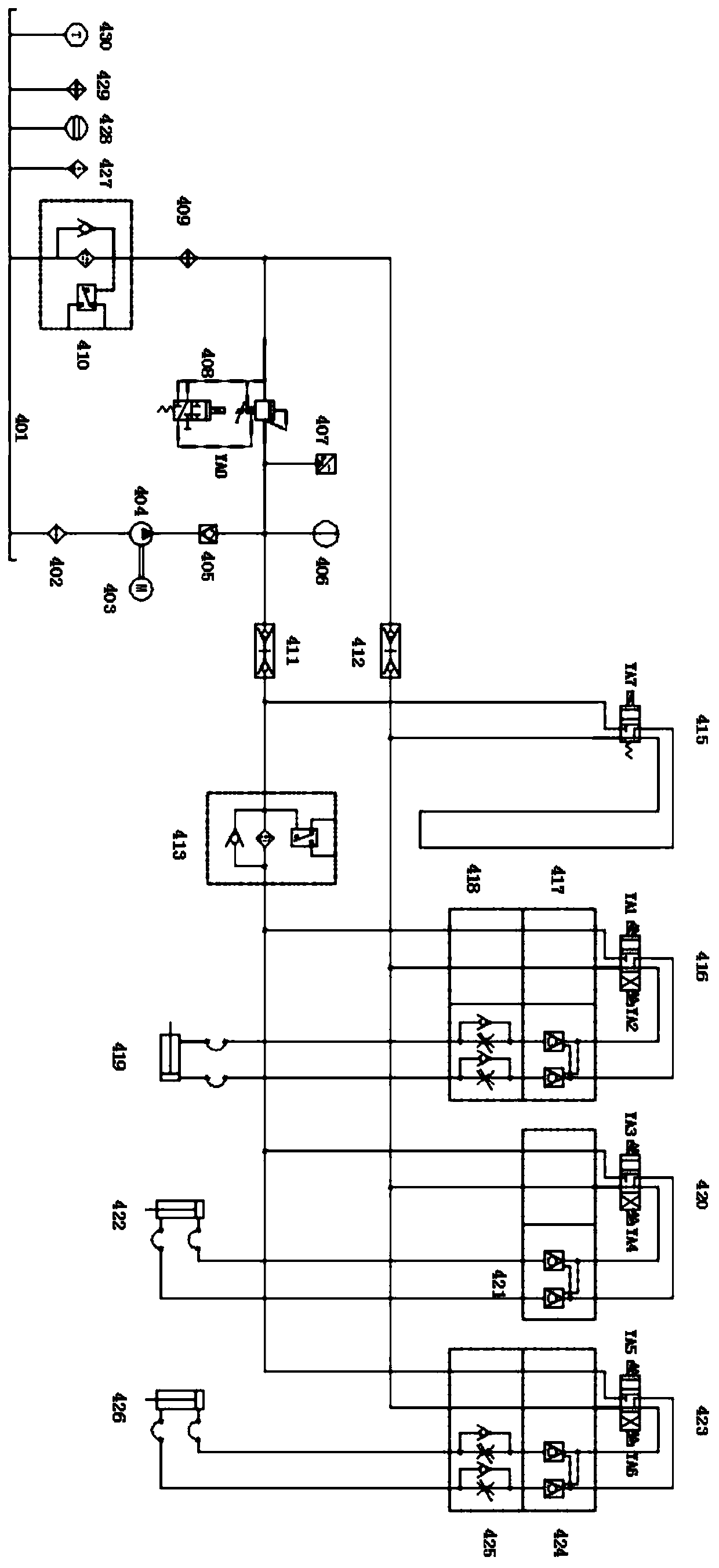

[0061] Such as Figure 4 As shown, a kind of full load sensitive control scraper type refuse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com