Classical garden rockery suitable for cultivating green plants and processing method of rockery

A kind of rockery and classical technology, applied in the field of classical garden rockery and its processing, can solve the problems affecting the environment, achieve the effects of beautifying and purifying the environment, good appearance quality, and excellent compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

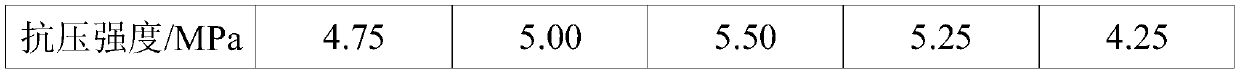

Embodiment 1

[0044] Processing of rockery:

[0045] (1) Mold making: the mold includes an outer mold and an inner mold, and the mold is made according to the established rockery structure;

[0046] (2) Mixing materials: 60kg blast furnace expanded slag of 80 meshes, 30kg Class I fly ash, 20kg Portland cement, 13kg lignocellulose, 10kg asbestos wool, 3kg cement additive hydrolyzed polymaleic anhydride, 5kg binder Styrene-butadiene copolymer and 5kg lubricant talcum powder are added in the mixer, mixed for 10min at a rotating speed of 800r / min, and mixed evenly to obtain the rockery processing material;

[0047] (3) Pouring: import the above-mentioned materials into the mold, insert the vibrating rod into the mold, vibrate and tamp the material, and replenish the material until the material is tamped and flush with the mold opening;

[0048] (4) Demoulding: The material is cured and molded for 48 hours under natural conditions of 25°C, and the outer mold and the inner mold are separated to ...

Embodiment 2

[0051] Taking Example 1 as a comparison, set up Example 2 in which the cement admixture is replaced by hydrolyzed polymaleic anhydride with an equivalent amount of polyaspartic acid, and the rest of the processing operations are exactly the same as Example 1.

Embodiment 3

[0053] Taking Example 1 as a comparison, Example 3 in which structure densification is added during the processing of the rockery is provided, and the rest of the processing operations are exactly the same as Example 1.

[0054] Processing of rockery:

[0055] (1) Mold making: the mold includes an outer mold and an inner mold, and the mold is made according to the established rockery structure;

[0056] (2) Mixing materials: 60kg blast furnace expanded slag of 80 meshes, 30kg Class I fly ash, 20kg Portland cement, 13kg lignocellulose, 10kg asbestos wool, 3kg cement additive hydrolyzed polymaleic anhydride, 5kg binder Styrene-butadiene copolymer and 5kg lubricant talcum powder are added in the mixer, mixed for 10min at a rotating speed of 800r / min, and mixed evenly to obtain the rockery processing material;

[0057] (3) Pouring: import the above-mentioned materials into the mold, insert the vibrating rod into the mold, vibrate and tamp the material, and replenish the material un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com