Easy-to-weld container plate with thickness ranging from 40 millimeters to 60 millimeters and excellent center low-temperature toughness, and making method thereof

A technology of low temperature toughness and manufacturing method, applied in the field of metal materials, can solve the problems of high service temperature, unable to guarantee the low temperature impact toughness of the steel plate core, unable to meet the technical requirements of steel for extra-large spherical tanks, etc., and achieves low production cost and excellent quality. The low temperature impact toughness of the core and the effect of pure molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

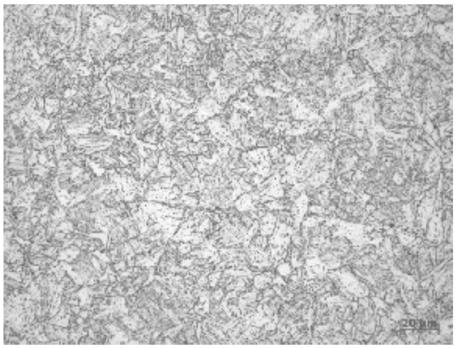

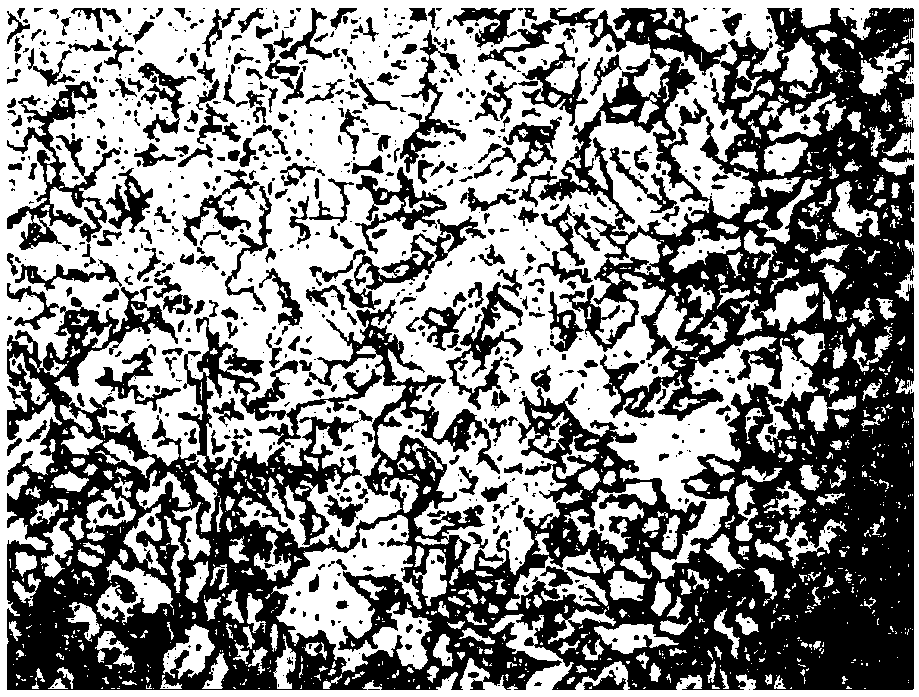

[0031]The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

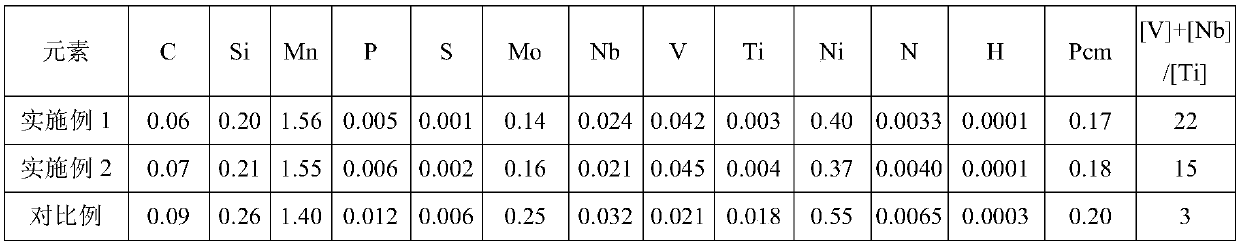

[0032] The smelting chemical compositions of this embodiment and the comparative example are shown in Table 1 (wt%), and the remainder is Fe and unavoidable impurity elements.

[0033] Table 1

[0034]

[0035] The above-mentioned examples and comparative examples were all smelted in the top-bottom combined blowing converter, then went through deep desulfurization and refining treatment in the ladle furnace, and finally went to the vacuum furnace for degassing and soft blowing for more than 15 minutes to fully float and remove large inclusions and ensure the composition Evenly, and then poured into continuous casting slabs by light pressing and protection throughout the process.

[0036] Heat the continuous casting slab to 1170-1220°C, the total time in the furnace is ≥370min, and the soaking time is ≥60min. The starting temperature of rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com