Thermal barrier coating containing YAG: Ce and preparation method and application thereof

A technology of thermal barrier coating and stress, applied in coating, metal material coating process, fusion spraying, etc., can solve the problem of inability to accurately monitor coating stress distribution and evolution, low sensitivity of stress-frequency shift factor, and accurate measurement Can not be realized and other problems, to achieve the effect of easy industrialized large-scale production, accurate and safe service life, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In a preferred embodiment of the present invention, the preparation method of YAG:Ce powder comprises the following steps: YAG 3 Al 5 o 12 and CeO 2 After mixing, sintering and grinding, YAG:Ce powder is obtained.

[0059] In a preferred embodiment of the present invention, the particle size of the YAG:Ce powder is 300-400 mesh, so that when the YAG:Ce powder is sprayed to prepare the fluorescent stress sensing layer, it is easier to spray uniformly. Compared with the above particle size range, when the particle size of YAG:Ce powder is too small, the spraying process used is not easy to produce powder, resulting in uneven coating, and the spraying efficiency is low; when the particle size of YAG:Ce powder is too large, the coating inside High porosity and low oxidation resistance.

[0060] Typically, but not limitatively, the particle size of the YAG:Ce powder is 300 mesh, 320 mesh, 350 mesh, 380 mesh or 400 mesh.

[0061] In a preferred embodiment of the present ...

Embodiment 1

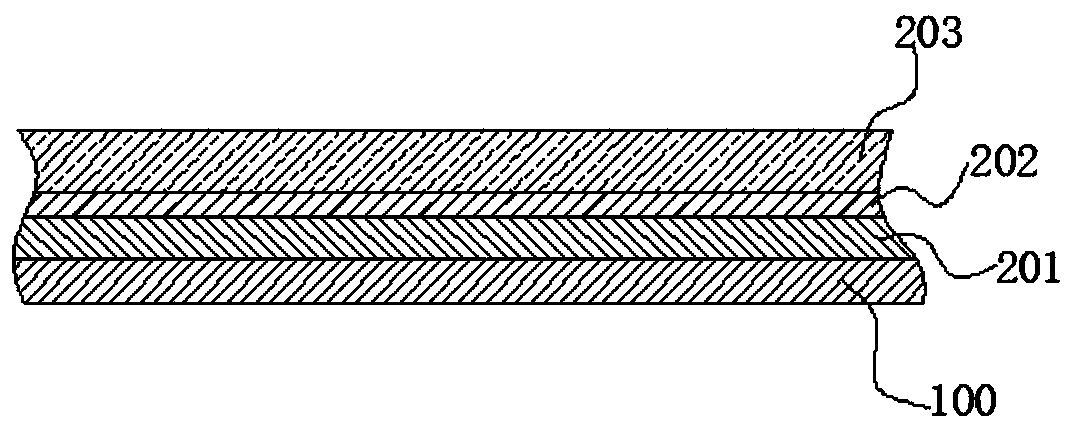

[0098] This embodiment provides a test piece containing YAG:Ce thermal barrier coating, its structure is as follows figure 1 As shown, the test piece includes a nickel alloy substrate 100, and a thermal barrier coating containing YAG:Ce adhered to the nickel alloy substrate 100, and the thermal barrier coating containing YAG:Ce includes sequentially arranged from bottom to top Metal bonding layer 201, fluorescent stress sensing layer 202 and ceramic layer 203, the material of described metal bonding layer 201 is NiCoCrAlY, thickness is 150 μm, fluorescent stress sensing layer 202 is formed by YAG:Ce powder spraying, and thickness is 20 μm, the material of the ceramic layer 203 is Y 2 o 3 Stable ZrO 2 , the thickness is 180 μm, and the fluorescent stress sensing layer is formed by spraying YAG:Ce powder with a particle size of 300 mesh, and the preparation raw material of YAG:Ce powder is Y 3 Al 5 o 12 and CeO 2 , the molar ratio of the two is 99.5:0.5, and the purity of ...

Embodiment 2

[0100] This embodiment provides a test piece of a thermal barrier coating containing YAG:Ce. The structure of the test piece is the same as in Example 1, and will not be repeated here. The difference between it and Example 1 is that the preparation of YAG : Among the raw materials of Ce powder, Y 3 Al 5 o 12 and CeO 2 The molar ratio is 99:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com