Adjusting system and method for preventing probe mark from deviating in wafer test

A wafer testing and adjustment system technology, applied in electronic circuit testing, electrical measurement, and measurement devices, etc., can solve problems such as human judgment differences, reduce machine utilization, and fail to find test problems in time, and achieve the effect of ensuring test quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention. The expression of the structural position of each component such as up, down, top, bottom, etc. in the description is not absolute, but relative. These directional expressions are appropriate when the various components are arranged as shown in the drawings, but when the positions of the various components in the drawings are changed, these directional expressions are also changed accordingly.

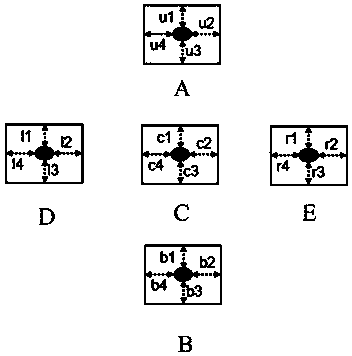

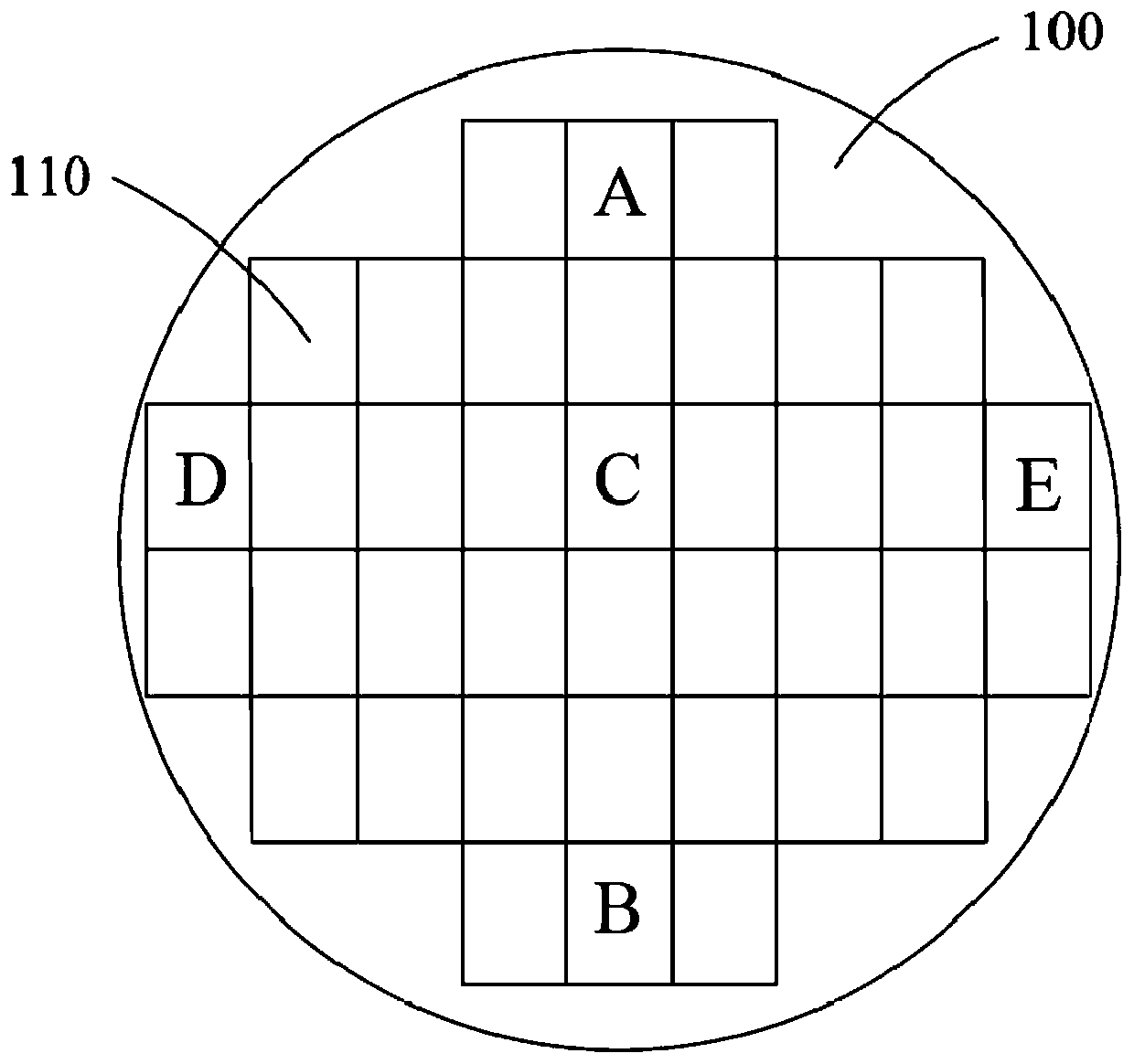

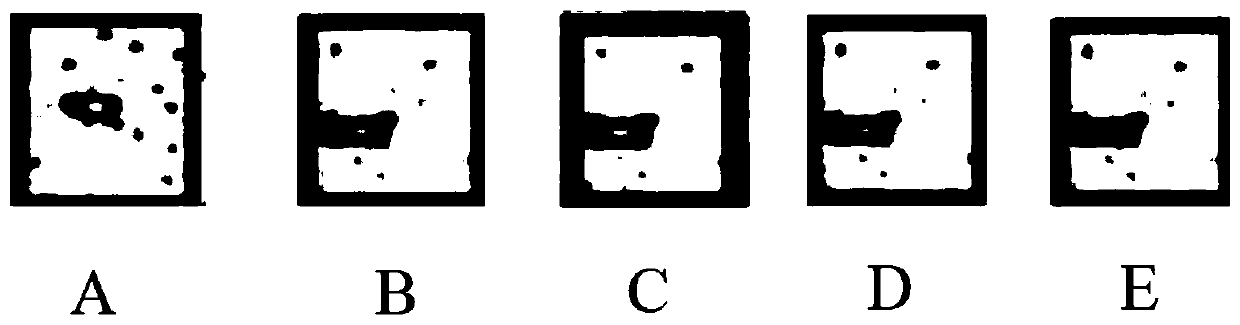

[0030] Wafer testing is aimed at the complete die on the entire chip, and the pads on each die are tested by means of probes, which are used to screen the good and bad products of the die on the chip. Wafer testing is to use the combination of testing machine, needle testing machine and probe card to test each die on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com