A method for predicting sewage parameters and a sewage forecasting system

A prediction method and technology for sewage parameters, applied in prediction, measurement device, data processing application, etc., can solve the problems of increasing sewage treatment cost, short sensor life, and high pollutant concentration, and achieve the goal of reducing hardware input cost and avoiding drug waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

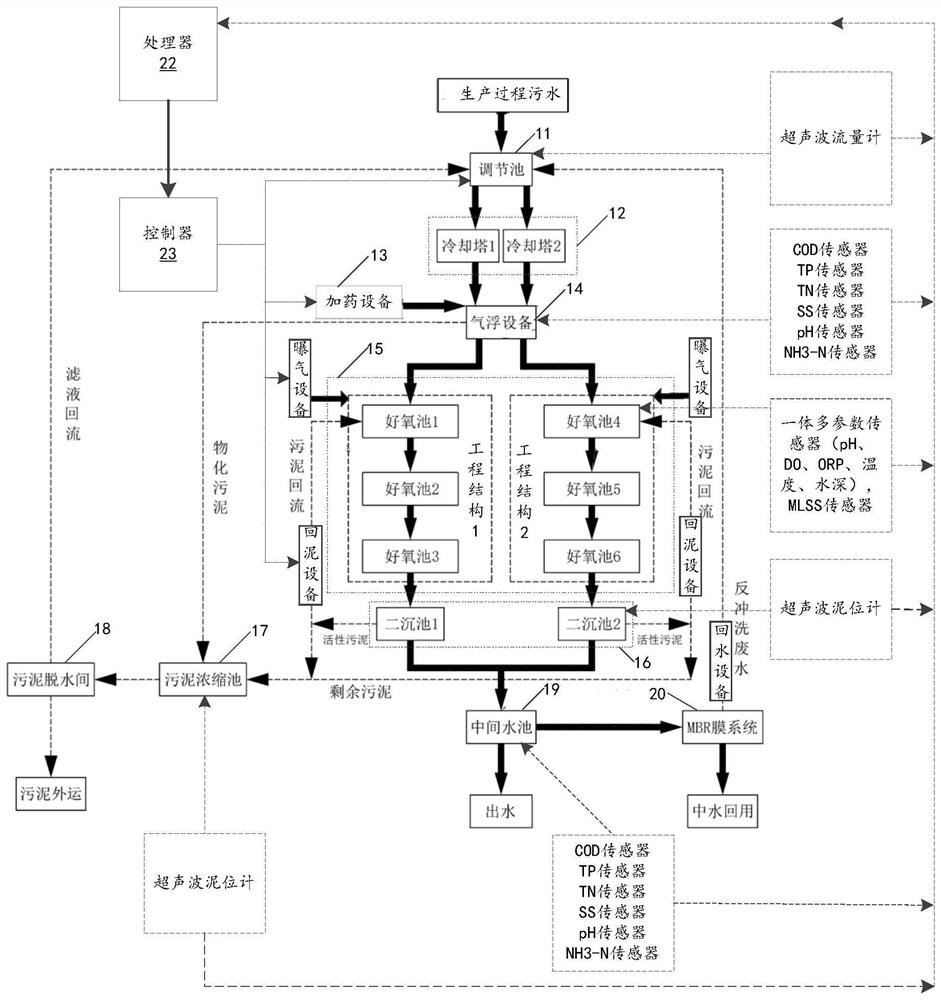

[0055] Please refer to figure 1 , the application discloses a sewage forecasting system, which includes a regulating tank 11, a cooling tower 12, a dosing device 13, an air flotation device 14, a biochemical tank 15, a secondary settling tank 16, a sludge concentration tank 17, and a sludge dehydration room 18 , an intermediate pool 19, a processor 22 and a controller 23. They will be explained separately below.

[0056] The regulating pool 11 is used to receive the sewage generated in the production process of the production equipment, and regulate the amount and quality of the sewage. In general, the quantity and quality of the sewage discharged during the production process have great changes in different time periods. In order to make the back-end sewage treatment process work normally, the discharged sewage should pass through a pool with a certain capacity and stay for a certain period of time. Make the peak flow or high-concentration sewage mixed evenly in the pool, t...

Embodiment 2

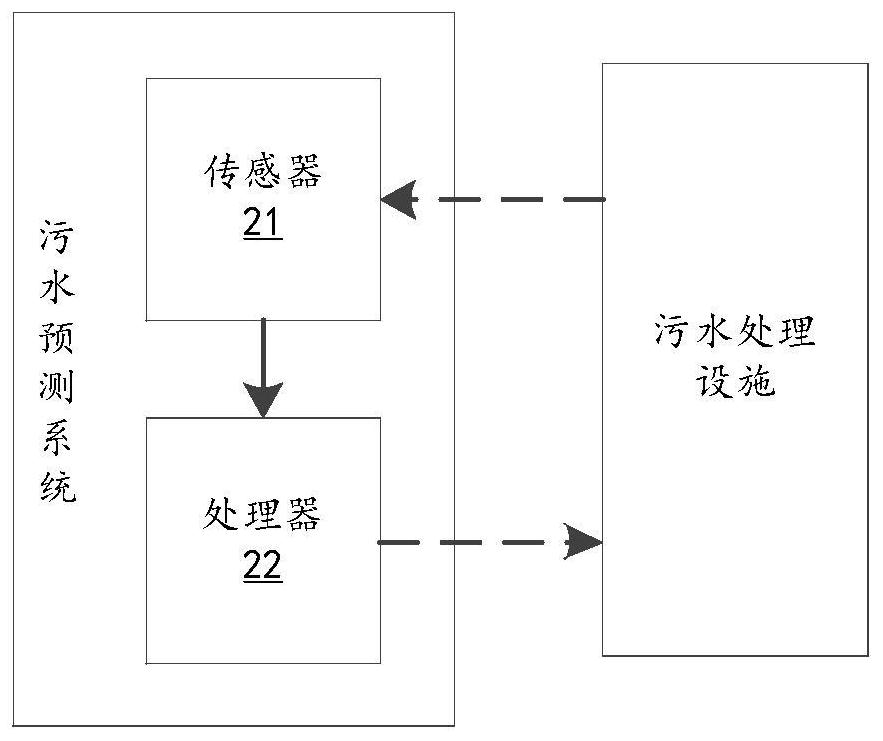

[0074] Please refer to figure 2 , the present application discloses a sewage forecasting system, which includes one or more sensors, and a processor 22 . Instructions are given below.

[0075] Such as figure 1 One or more sensors (such as reference numeral 21) shown in, these sensors 21 are used for monitoring one or more parameters in the sewage; Each sensor point can be equipped with a sensor for monitoring one or more parameters in sewage, and only some of the multiple sensor points are equipped with sensors for monitoring one or more parameters in sewage . Specifically, the sensor 21 is used to be arranged at one or more treatment links of the sewage treatment facility to acquire measurement parameters of each sensor point in real time.

[0076] It should be noted that the sensors involved in this embodiment include COD sensors, TP sensors, TN sensors, pH sensors, SS sensors, MLSS sensors, NH3-N sensors, ultrasonic mud level meters, ultrasonic flow meters, and One or...

Embodiment 3

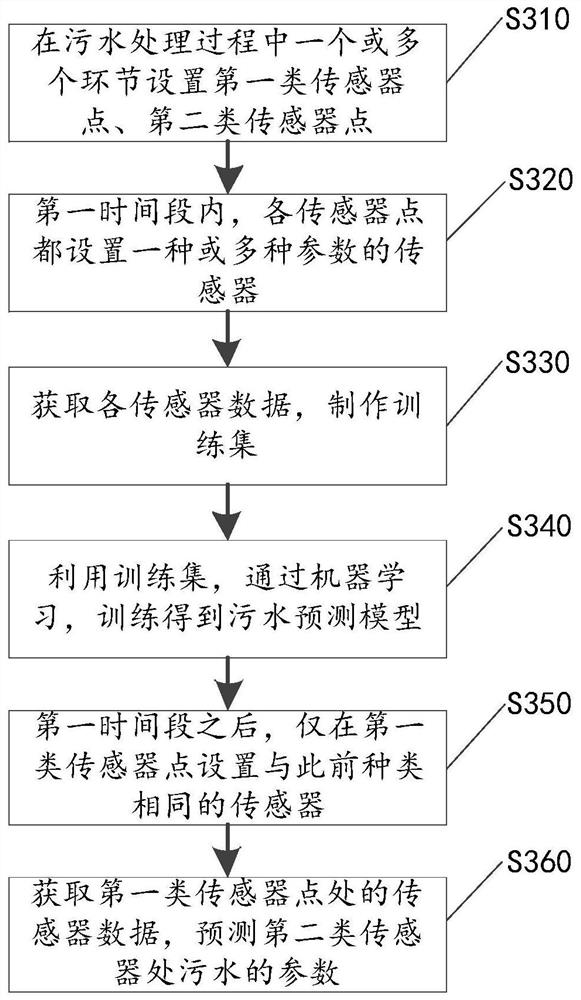

[0080] Please refer to image 3 , on the basis of the sewage prediction system disclosed in Embodiment 1, the present application discloses a sewage parameter prediction method, which includes steps S310-S360, which will be described separately below.

[0081] Step S310, the user sets multiple sensor points at one or more links in the sewage treatment process, and each sensor point can be set with a sensor for monitoring one or more parameters in the sewage; the sensor points are divided into first class of sensor points and sensor points of the second class.

[0082] Step S320, within the first period of time, set a sensor for monitoring one or more parameters in the sewage at each sensor point.

[0083] In step S330, the processor 22 obtains the data of each sensor through the sensors at each sensor point; a training set is made according to the acquired sensor data, wherein the data in the training set is the data of the sensors at the sensor points of the first type, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com