Cloth defect detection device and method

A detection method and detection device technology, which are applied in image data processing, instrumentation, calculation, etc., can solve problems such as difficulties, and achieve the effects of improving detection rate, reducing production cost, and improving acquisition quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

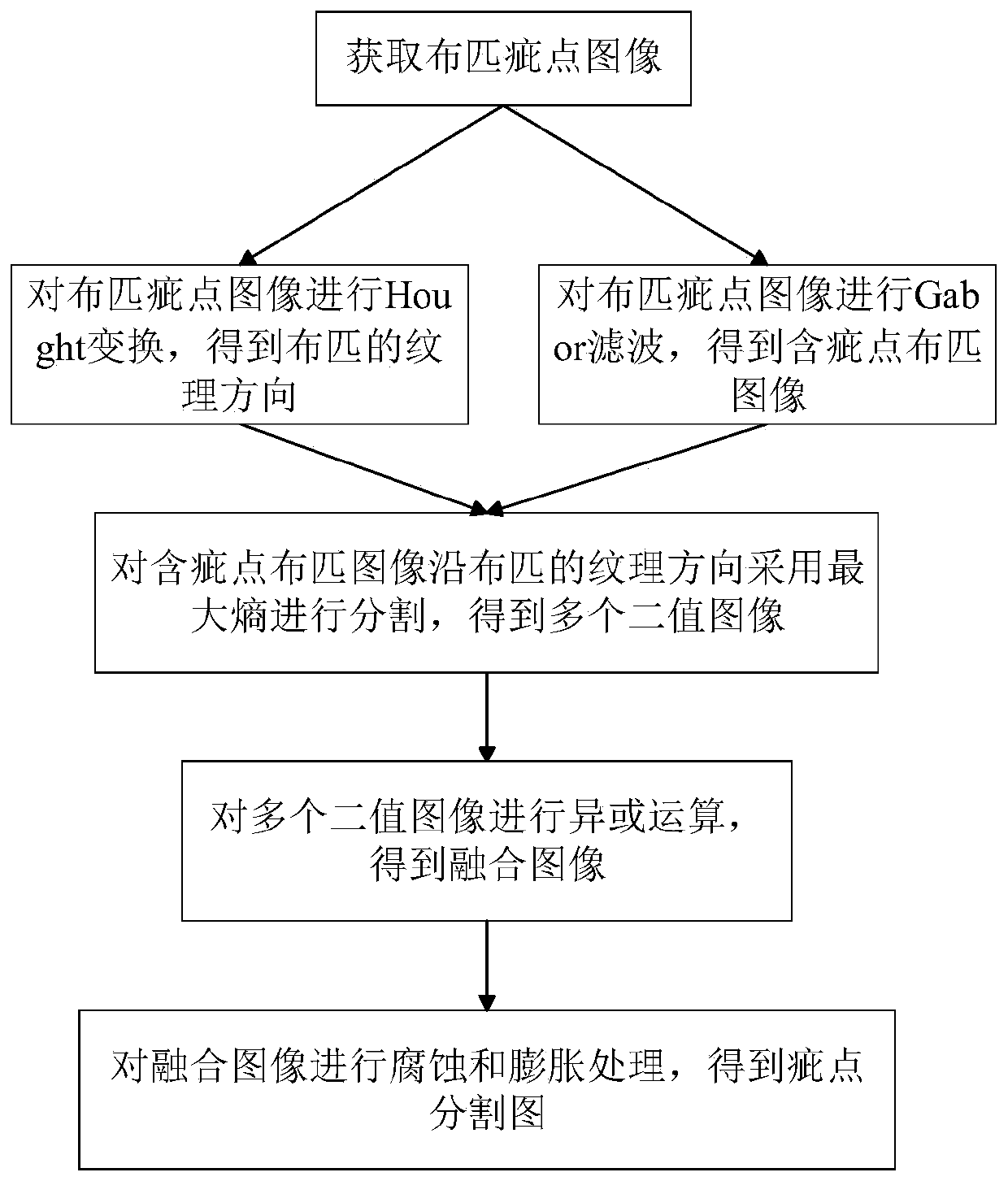

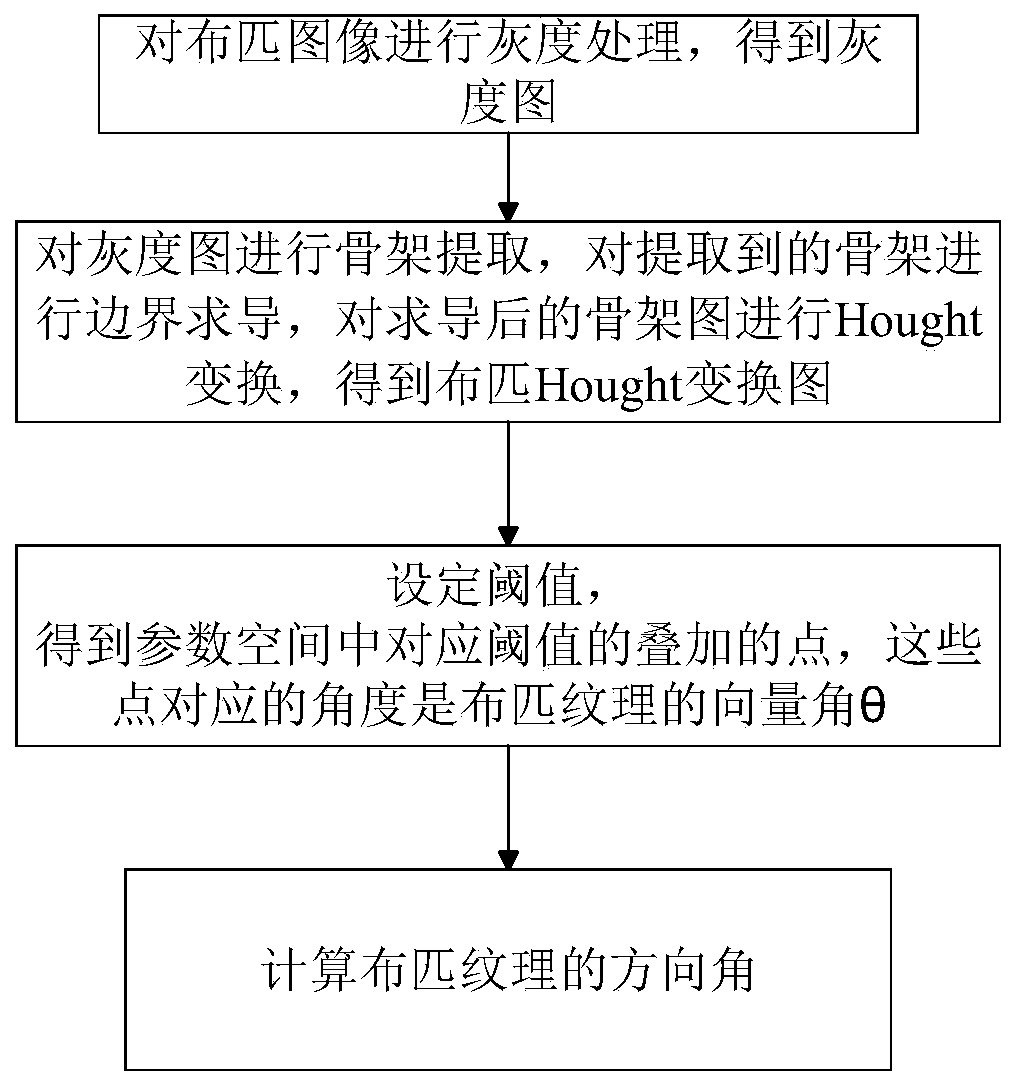

[0037] Such as figure 1 As shown, the Hough transform is used to detect straight lines and curves, and the degree of overlap of defects can be found to determine the degree of collinearity of the straight lines in the image; by selecting the modulus image, the cloth image with defects can be obtained through Gabort transform. By performing histogram equalization processing on the image, the dynamic range of the image pixels is increased to reduce the influence of light, and then the image is Gaussian filtered to obtain a smooth image. The image with defects after Gabor filtering is segmented by maximum entropy to obtain a binary image, and the segmented images along the direction of the cloth image texture are fused by XOR operation to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com