Supramolecular microporous framework material supported by functionalized caged borane anion pillars and its preparation method and application

A technology of anion column and frame material, which is applied in separation methods, chemical instruments and methods, adsorption purification/separation, etc., can solve the problems that need to be studied in application, achieve good structural stability, and realize the effect of selective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In a 50mL round-bottomed flask, 242mg (1mmol) of Cu(NO 3 ) 2 ·3H 2 O and 314mg (1mmol) of Na 2 B 12 H 11 I was dissolved in 10 ml of water. In another 25 mL round bottom flask, 360 mg (2 mmol) of 4,4'-dipyridine acetylene was dissolved in 15 mL methanol. The methanol solution was slowly added to the aqueous solution and stirred at 25°C for 24 hours to obtain a grayish purple solid precipitate, which was filtered and washed with methanol. Replace the above solid in anhydrous methanol 3 times with an interval of 12 hours each time to remove the water molecules in the material pores, and then vacuum and degas at 70℃ for 10 hours to obtain activated functionalized cage-like dodecaborane anion supramolecules Microporous frame material, named BSF-20.

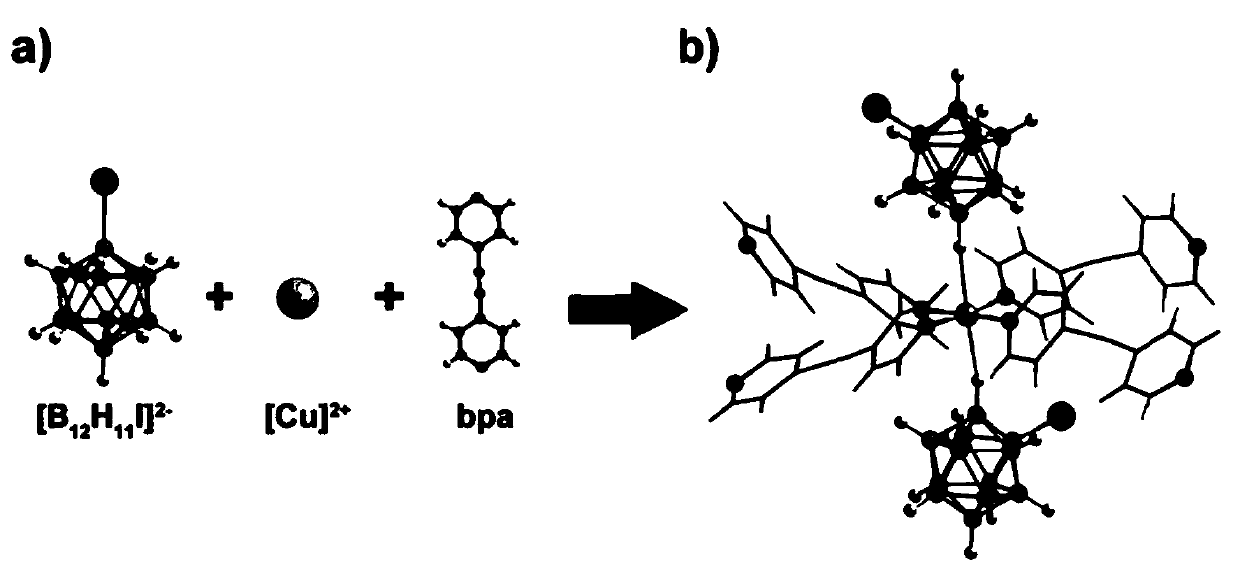

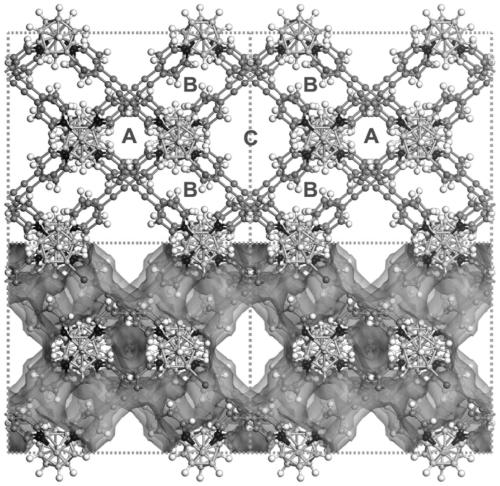

[0036] The self-assembly behavior of BSF-20 is as figure 1 Shown. First, the metallic copper ion is coordinated to four different pyridine rings in the horizontal direction, and to the B-H of two different caged boranes in the ...

Embodiment 2

[0054] In a 50mL round-bottomed flask, 242mg (1mmol) of Cu(NO 3 ) 2 ·3H 2 O and 314mg (1mmol) of Na 2 B 12 H 11 I was dissolved in 10 ml of water. In another 25 mL round bottom flask, 312 mg (2 mmol) of bipyridine was dissolved in 15 mL methanol. The methanol solution was slowly added to the aqueous solution and stirred at 25°C for 2 hours to obtain a grayish purple solid precipitate, which was filtered and washed with methanol. Replace the above solid in anhydrous methanol 3 times with an interval of 12 hours each time to remove the water molecules in the material pores, and then vacuum degas and activate at 80°C for 5 hours to obtain activated functionalized caged dodecaborane anion supramolecules The microporous frame material is named BSF-21.

Embodiment 3

[0056] In a 50mL round-bottomed flask, 242mg (1mmol) of Cu(NO 3 ) 2 ·3H 2 O and 314mg (1mmol) of Na 2 B 12 H 11 I was dissolved in 10 ml of water. In another 25 mL round bottom flask, 464 mg (2 mmol) of bipyridinebenzene was dissolved in 15 mL of methanol. The methanol solution was slowly added to the aqueous solution and stirred at 25°C for 48 hours to obtain a grayish purple solid precipitate, which was filtered and washed with methanol. Replace the above solid in anhydrous methanol 3 times with an interval of 8 hours each time to remove the water molecules in the material pores, and then vacuum degas and activate for 10 hours at 100°C to obtain activated functionalized cage-like dodecaborane anion supramolecules The microporous frame material is named BSF-22.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com