Milling processing process for LD5-CS free forging angle-closure deep cavity structural parts

A technology of LD5-CS and structural parts, which is applied in the milling processing technology of free forging aluminum alloy parts, and the milling processing technology of LD5-CS free forging closed angle deep cavity structural parts, which can solve the problem of parts that cannot meet the design requirements and cutting Low efficiency, long processing time and other problems, to achieve the effect of meeting the delivery of production nodes, saving processing costs, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

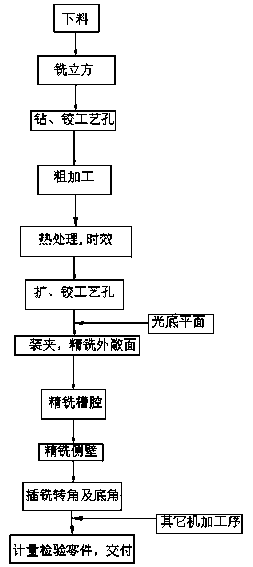

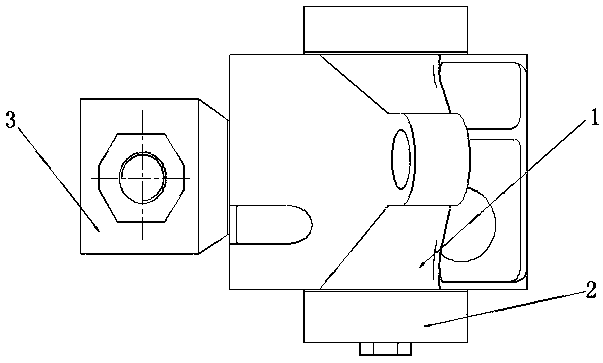

[0037] Attached below Figure 1-4 The present invention is described in further detail: as Figure 1-4 As shown, a milling process of LD5-CS free forging closed angle deep cavity structural parts includes the following steps:

[0038] (1) Blanking: Determine the material grade and furnace batch number of the part, so that the size tolerance of the cubic material to be placed is within +5~+10mm;

[0039] (2) Milling cube: The upper and lower bottom surfaces of the milling cube ensure a flatness of 0.1;

[0040] (3) Drilling and reaming process holes: The purpose is to determine the origin of processing, but in actual drilling, it is very easy to burn the knife, break the drill, etc., it should be noted that the cutting depth is divided into multiple advances and retreats for processing, and the coolant should be replenished in time , Change the drill bit frequently.

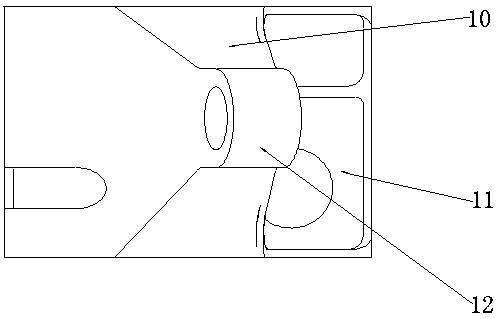

[0041] (4) Rough processing: such as figure 2 As shown, the rough machining of the free forging aluminum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com