A Milling Technology of ld5-cs Free Forging Closed Angle Deep Cavity Structural Parts

A technology of LD5-CS and structural parts, which is applied to the milling processing technology of free forging aluminum alloy parts, and the milling processing technology field of LD5-CS free forging closed angle deep cavity structural parts, which can solve the problems that cannot meet the design requirements and the groove cavity Problems such as expansion and low cutting efficiency of parts can be achieved to meet the delivery of production nodes, reduce tool costs and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

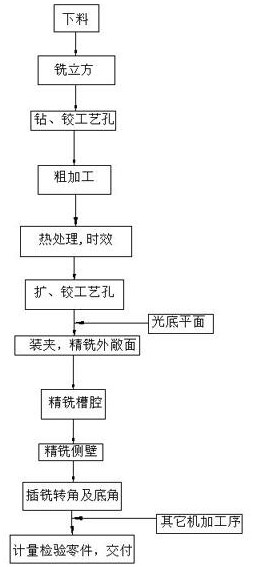

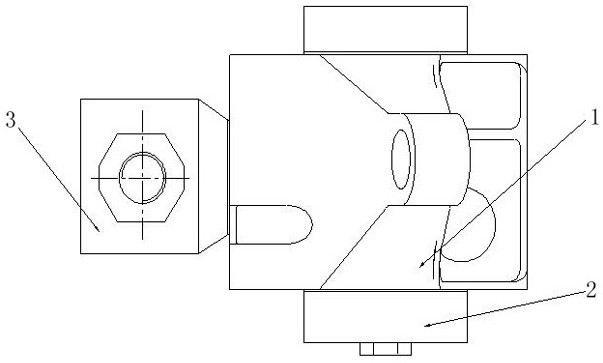

[0037]By the followingFigure 1-4 Further detailed in the present invention:Figure 1-4 As shown, the milling process of the LD5-CS freely forging the corner cavity structure part includes the following steps:

[0038](1) Upper materials: Determine the part material number, the furnace number, so that the underwash size tolerance is guaranteed within + 5 ~ + 10mm;

[0039](2) Milling Cube: The milling cube is rotated in the bottom surface of 0.1;

[0040](3) Diamond, hinge process hole: The purpose is to determine the processing origin, but in the actual drilling, it is easy to have a burnt knife, disconnect diamonds, etc., pay attention to take a small cutult to retrieve the retrieval processing, and supplement the coolant in time. , Change the drill bit.

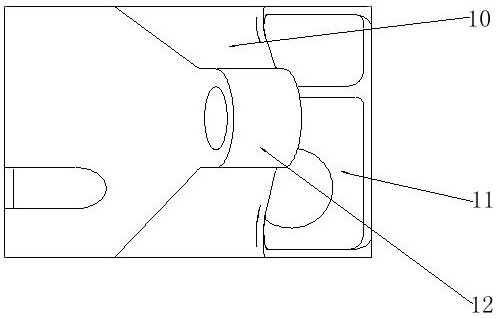

[0041](4) Rough processing:figure 2 As shown, the roughing of the freely forged aluminum alloy parts contains three aspects, one is the outer spacing slope 10, and the second is the lucite 11, and the third is the end 12. When the coarse proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com