Full-polylactic acid fiber mattress cover and manufacturing process thereof

A technology of polylactic acid fiber and polylactic acid, which is applied to mattresses, spring mattresses, and other seating furniture, can solve the problems of high cost and little increase in usage, and achieve easy cleaning and care, good comfort Sexuality, the effect of mitigating environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

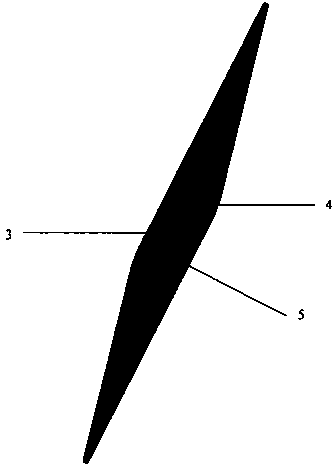

Image

Examples

Embodiment

[0029] Polylactic acid fiber is supported by spinning, spinning weaving, and non-woven technologies. The polylactic acid fabric produced has good strength, comfort, health and safety, and the fiber filling made of it has good warmth retention. The bed sheet of the present invention is made of polylactic acid knitted fabric, polylactic acid fiber filler and polylactic acid spun-bonded non-woven fabric.

[0030] The full polylactic acid fiber bed sheet of the present invention comprises surface layer, filling layer, bottom layer and bounding;

[0031] The surface layer and hemming are made of polylactic acid knitted fabric, and the bottom layer is made of polylactic acid spun-bonded non-woven fabric.

[0032] The filling layer is made of fiber flakes carded from polylactic acid tows and laminated.

[0033] The manufacturing process of the bed sheet of full polylactic acid fiber of the present invention comprises:

[0034] Making polylactic acid fiber flakes:

[0035] The poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com